Difference between revisions of "Mechanical engineering" - New World Encyclopedia

William Salt (talk | contribs) |

William Salt (talk | contribs) m (→Tools and Work) |

||

| Line 65: | Line 65: | ||

The process of engineering design is, as described by Pahl and Beitz, "the intellectual attempt to meet certain demands in the best way possible.... an engineering activity that impinges on nearly every sphere of human life, relies on the discoveries and laws of science, and creates the conditions for applying these laws to the manufacture of useful products." (''Engineering Design'') | The process of engineering design is, as described by Pahl and Beitz, "the intellectual attempt to meet certain demands in the best way possible.... an engineering activity that impinges on nearly every sphere of human life, relies on the discoveries and laws of science, and creates the conditions for applying these laws to the manufacture of useful products." (''Engineering Design'') | ||

| − | There are four main phases to engineering design: | + | There are generally four main phases to engineering design: |

*Clarification of Task | *Clarification of Task | ||

*Conceptual Design | *Conceptual Design | ||

| Line 71: | Line 71: | ||

*Detail Design | *Detail Design | ||

| − | Basic | + | Basic aspects of design include: |

*Design Concept | *Design Concept | ||

:*Systems Engineering (function, safety, reliability, maintainability) | :*Systems Engineering (function, safety, reliability, maintainability) | ||

| Line 79: | Line 79: | ||

==Tools and Work== | ==Tools and Work== | ||

| − | |||

Modern analysis and design processes in mechanical engineering are aided by various computational tools including [[finite element analysis]] (FEA), [[computational fluid dynamics]] (CFD), [[computer-aided design]] (CAD)/[[computer-aided manufacturing]] (CAM) and Failure Modes & Effect Analysis (FMEA). These modern processes facilitate engineers to model (create a 3D object in a computer), analyze the quality of design etc, before a prototype is created. By this the invention and experimenting with new designs becomes very easy and can be done without any money invested in tooling and prototypes. Simple models can be free and instantaneous, but complicated models, like those describing the mechanics of living tissue, can require years to develop, and the actual computation can be very processor intensive, requiring powerful computers and a lot of cycle time. | Modern analysis and design processes in mechanical engineering are aided by various computational tools including [[finite element analysis]] (FEA), [[computational fluid dynamics]] (CFD), [[computer-aided design]] (CAD)/[[computer-aided manufacturing]] (CAM) and Failure Modes & Effect Analysis (FMEA). These modern processes facilitate engineers to model (create a 3D object in a computer), analyze the quality of design etc, before a prototype is created. By this the invention and experimenting with new designs becomes very easy and can be done without any money invested in tooling and prototypes. Simple models can be free and instantaneous, but complicated models, like those describing the mechanics of living tissue, can require years to develop, and the actual computation can be very processor intensive, requiring powerful computers and a lot of cycle time. | ||

| Line 112: | Line 111: | ||

Mechatronics is currently used in the following areas of engineering: | Mechatronics is currently used in the following areas of engineering: | ||

| − | *[[Automation]], and | + | *[[Automation]], and [[robotics]]. |

*[[servomechanism|Servo-Mechanics]] | *[[servomechanism|Servo-Mechanics]] | ||

*[[sensor|Sensing]] and [[control system|Control Systems]] | *[[sensor|Sensing]] and [[control system|Control Systems]] | ||

| − | *[[Automotive engineering]], in the design of subsystems such as [[anti-lock braking system]]s | + | *[[Automotive engineering]], in the design of subsystems such as [[anti-lock braking system]]s, as well as engine design, gear design, and other moving parts. |

*[[Computer engineering]], in the design of mechanisms such as hard drives, CD-ROM drives, etc. | *[[Computer engineering]], in the design of mechanisms such as hard drives, CD-ROM drives, etc. | ||

| Line 121: | Line 120: | ||

'''Robotics''' is the application of mechatronics to create robots, which perform tasks that are dangerous, unpleasant, or repetitive. These robots may be of any shape and size, but all are preprogrammed and interact physically with the world. To create a robot, an engineer typically employs kinematics (to determine the robot's range of motion) and mechanics (to determine the [[Stress (physics)|stress]]es within the robot). | '''Robotics''' is the application of mechatronics to create robots, which perform tasks that are dangerous, unpleasant, or repetitive. These robots may be of any shape and size, but all are preprogrammed and interact physically with the world. To create a robot, an engineer typically employs kinematics (to determine the robot's range of motion) and mechanics (to determine the [[Stress (physics)|stress]]es within the robot). | ||

| − | Robots are used extensively in [[Industrial engineering]]. They allow businesses to save money on labor and perform tasks that are either too dangerous or too precise for humans to perform them economically. Many companies employ [[assembly lines]] of robots, and some factories are so | + | Robots are used extensively in [[Industrial engineering]]. They allow businesses to save money on labor and perform tasks that are either too dangerous or too precise for humans to perform them economically. Many companies employ [[assembly lines]] of robots, and some factories are so roboticized that they can run [[Lights out (manufacturing)|by themselves]]. Outside the factory, robots have been employed in bomb disposal, [[space exploration]], and many other fields. Robots are also sold for various residential applications. |

=== Structural analysis === | === Structural analysis === | ||

| Line 135: | Line 134: | ||

Structural analysis may be used the office when designing parts, in the field to analyze failed parts, or in laboratories where parts might undergo controlled failure tests. | Structural analysis may be used the office when designing parts, in the field to analyze failed parts, or in laboratories where parts might undergo controlled failure tests. | ||

| − | === Thermodynamics | + | === Thermodynamics=== |

{{Main|Thermodynamics}} | {{Main|Thermodynamics}} | ||

| − | '''[[Thermodynamics]]''' is an applied science used in several branches of engineering, including Mechanical and [[Chemical Engineering]]. At its simplest, thermodynamics is the study of energy, its use and transformation through a [[physical system|system]]. Typically, engineering thermodynamics is concerned with changing energy from one form to another. As an example, automotive engines convert chemical energy ([[enthalpy]]) from the fuel into heat, and then into mechanical work that eventually turns the wheels. | + | '''[[Thermodynamics]]''' is an applied science used in several branches of engineering, including Mechanical and [[Chemical Engineering]]. At its simplest, thermodynamics is the study of energy, its use, and its transformation through a [[physical system|system]]. Typically, engineering thermodynamics is concerned with changing energy from one form to another. As an example, automotive engines convert chemical energy ([[enthalpy]]) from the fuel into heat, and then into mechanical work that eventually turns the wheels. |

| − | + | Thermodynamic principles are used by mechanical engineers in the fields of [[heat transfer]], [[thermofluids]], and [[energy conversion]]. Mechanical engineers consider thermodynamics in the design of [[engine]]s and [[power plant]]s, heating, ventilation, and air-conditioning ([[HVAC]]) systems, [[heat exchanger]]s, [[heat sink]]s, [[radiator]]s, [[refrigeration]], [[Thermal insulation|insulation]], and other applications that require the movement of energy, work, or the conversion of one into the other. | |

=== Drafting === | === Drafting === | ||

| Line 180: | Line 179: | ||

===Mechatronics=== | ===Mechatronics=== | ||

{{Main|Mechatronics}} | {{Main|Mechatronics}} | ||

| + | |||

| + | ===Biomechanics=== | ||

== See also == | == See also == | ||

Revision as of 19:57, 6 July 2007

Mechanical Engineering is the engineering discipline that involves the application of principles of physics for analysis, design, manufacturing, and maintenance of mechanical systems. It requires a solid understanding of key concepts including mechanics, kinematics, thermodynamics and energy. Mechanical Engineers use these principles and others in the design and analysis of automobiles, aircraft, heating & cooling systems, manufacturing plants, industrial equipment, machinery, and more.

History

Mechanical engineering could be found in many ancient and medieval societies throughout the globe. In ancient Greece, there were brilliant mechanical engineers such as Archimedes (287-212 B.C.E.), as well as Heron of Alexandria (10-70 C.E.). The mechanical works of the latter two deeply influenced mechanics in the Western tradition, although there were many others who contributed to early mechanical science. In ancient China, there were also many notable figures, such as Zhang Heng (78-139 C.E.) and Ma Jun (200-265 C.E.). The medieval Chinese horologist and engineer Su Song (1020-1101 C.E.) incorporated an escapement mechanism into his astronomical clock tower two centuries before any escapement could be found in clocks of medieval Europe, as well as the world's first known endless power-transmitting chain drive.

Before the Industrial Revolution, most engineering was for military and civil uses. Engineers in the military designed fortifications and various war machines. Civil engineers were primarily responsible for buildings and ground structures. "During the early 19th century in England mechanical engineering developed as a separate field to provide manufacturing machines and the engines to power them. The first British professional society of civil engineers was formed in 1818; that for mechanical engineers followed in 1847." In the United States, the first mechanical engineering professional society was formed in 1880, making it the third oldest type of engineering behind civil (1852) and mining & metallurgical (1871)." The first schools in the United States to offer an engineering education were the United States Military Academy in 1817, an institution now known as Norwich University in 1819, and Rensselaer Polytechnic Institute in 1825. An engineering education is based on a strong foundation in mathematics and science; this is followed by courses emphasizing the application of this knowledge to a specific field and studies in the social sciences and humanities to give the engineer a broader education.

Education

A Bachelor of Science (BS) / Bachelor of Arts (BA) degree in Mechanical Engineering is offered at many universities in the United States, and similar programs are offered at universities in most industrialized nations. In the U.S., Japan, Germany, Canada, Taiwan, South Korea, South Africa and many others, Mechanical Engineering programs typically take 4 to 5 years, and result in a Bachelor of Science in Mechanical Engineering or BSc (Mech Eng), but some countries like Singapore, Malaysia, India, and Nigeria offer a 4 year Bachelor of Science (BSc) / Bachelor of Engineering (BEng) degree with Honors (Hons) in Mechanical Engineering. In Australia and New Zealand, requirements are typically a 4 year Bachelor of Engineering (BE or BEng) degree, equivalent to the British MEng level. A BEng degree differ from a BSc degree in that the students obtain a broader education consisting of information relevant to various engineering disciplines.

Most Mechanical Engineering programs in the U.S. are accredited by Accreditation Board for Engineering and Technology (ABET) to ensure similar course requirements and standards between universities. The ABET web site lists 276 accredited Mechanical Engineering programs as of June 19, 2006.[1] Mechanical Engineering programs in Canada are accredited by the Canadian Engineering Accreditation Board (CEAB).[2]

Some Mechanical Engineers go on to pursue a postgraduate degree such as a Master of Engineering, Master of Science, Master of Engineering Management (MEng.Mgt, MEM), a Doctor of Philosophy in Engineering (DEng, PhD) or an Engineer's degree. The Master's and Engineer's degrees may consist of either research, coursework or a mixture of the two. The Doctor of Philosophy consists of a significant research component and is often viewed as the entry point to academia. [3]

Mechanical engineering coursework

Mechanical engineering programs generally cover the same fundamental subjects. Universities in the United States offering accredited programs in mechanical engineering are required to offer several major subjects of study, as determined by ABET. This is to ensure a minimum level of competence among graduating engineers and to inspire confidence in the engineering profession as a whole. The specific courses required to graduate, however, may differ from program to program. Universities will often combine multiple subjects into a single class or split a subject into multiple classes, depending on the faculty available and the University's major area(s) of research. Fundamental subjects of mechanical engineering include:

- statics & dynamics

- strength of materials & solid mechanics,

- instrumentation and measurement,

- thermodynamics, heat transfer, energy conversion, and refrigeration / air conditioning,

- fluid mechanics/fluid dynamics,

- mechanism design (including kinematics and dynamics),

- manufacturing technology or processes,

- hydraulics & pneumatics,

- engineering design,

- mechatronics and/or control theory,

- drafting, CAD (usually including Solid modeling), and CAM.[4][5]

Mechanical engineers are also expected to understand and be able to apply basic concepts from chemistry, chemical engineering, electrical engineering, and physics. Most mechanical engineering programs include several semesters of calculus, as well as advanced mathematical concepts which may include differential equations and partial differential equations, linear and modern algebra, and differential geometry, among others.

In addition to the core mechanical engineering curriculum, many mechanical engineering programs offer more specialized programs and classes, such as mechatronics / robotics, transport and logistics, cryogenics, fuel technology, automotive engineering, biomechanics, vibration, optics and others, if a separate department does not exist for these subjects.[6]

Most mechanical engineering programs also require varying amounts of research or community projects to gain practical problem-solving experience. Mechanical engineering students usually hold one or more internships while studying, though this is not typically mandated by the university.

License

After being awarded a degree, Engineers may seek license by a state or national government. The purpose of this process is to ensure that engineers possess the necessary technical knowledge and real-world experience to engineer safely. Once certified, the engineer is given the title of Professional Engineer (in the United States, Canada, Japan, South Korea and South Africa), Chartered Engineer (in the UK, Ireland, India and Zimbabwe), Chartered Professional Engineer (in Australia and New Zealand) or European Engineer (much of the European Union). Not all mechanical engineers choose to become licensed; those that do can be distinguished as Chartered/Professional Engineers by the post-nominal title PE or CEng, as in: Ryan Jones, PE.

In the U.S., to become a licensed Professional Engineer, an Engineer must

- pass the comprehensive FE (Fundamentals of Engineering) exam,

- work a given number of years as an Engineering Intern (EI) or Engineer-in-Training (EIT),

- pass the Principles and Practice or PE (Practicing Engineer or Professional Engineer) exam.

In the United States, the requirements and steps of this process are set forth by the National Council of Examiners for Engineering and Surveying (NCEES), website, a national non-profit representing all states. In the UK, current graduates require a MSc, MEng or BEng (Hons) in order to become chartered through the Institution of Mechanical Engineers.

"In most modern countries, certain engineering tasks, such as the design of bridges, electric power plants, and chemical plants, must be approved by a Professional Engineer or a Chartered Engineer."[7] In the USA and Canada, only a licensed engineer may seal engineering work for public and private clients.".[8] This requirement is written into state and provincial legislation, such as Quebec's Engineer Act.[9] In other countries, such as Australia, no such legislation exists; however, practically all certifying bodies maintain a code of ethics independent of legislation that they expect all members to abide by or risk expulsion.[10]

- (See Also: FE Exam | Professional Engineer | Chartered Engineer | Incorporated Engineer | Washington Accord)

Salaries and workforce statistics

The total number of engineers employed in the U.S. in 2004 was roughly 1.4 million. Of these, 226,000 were mechanical engineers (15.6%), second only in size to civil engineers at 237,000 (16.4%). The total number of mechanical engineering jobs in 2004 was projected to grow 9 to 17%, with average starting salaries being $50,236 with a bachelor's degree, $59,880 with a master's degree, and $68,299 with a doctorate degree. This places mechanical engineering at 8th of 14 among engineering bachelors degrees, 4th of 11 among masters degrees, and 6th of 7 among doctorate degrees in average annual salary.[11] The median annual earning of mechanical engineers in the U.S. workforce is roughly $63,000. This number is highest when working for the government ($72,500), and lowest when doing general purpose machinery manufacturing in the private sector ($55,850).[12]

Canadian engineers make an average of $28.10 per hour with 3% unemployed. The average for all occupations is $16.91 per hour with 5% unemployed. Eight percent of these engineers are self-employed, and since 1994 the proportion of female engineers has remained constant at 4%.[13]

Process of Mechanical Engineering

The process of engineering design is, as described by Pahl and Beitz, "the intellectual attempt to meet certain demands in the best way possible.... an engineering activity that impinges on nearly every sphere of human life, relies on the discoveries and laws of science, and creates the conditions for applying these laws to the manufacture of useful products." (Engineering Design)

There are generally four main phases to engineering design:

- Clarification of Task

- Conceptual Design

- Embodiment Design

- Detail Design

Basic aspects of design include:

- Design Concept

- Systems Engineering (function, safety, reliability, maintainability)

- Design of Elements (size, shape, material, life)

- Manufacturability (ease/difficulty with which a part can be made)

- Cost (planning, materials, construction)

Tools and Work

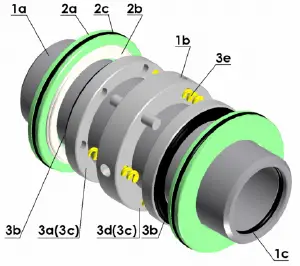

Modern analysis and design processes in mechanical engineering are aided by various computational tools including finite element analysis (FEA), computational fluid dynamics (CFD), computer-aided design (CAD)/computer-aided manufacturing (CAM) and Failure Modes & Effect Analysis (FMEA). These modern processes facilitate engineers to model (create a 3D object in a computer), analyze the quality of design etc, before a prototype is created. By this the invention and experimenting with new designs becomes very easy and can be done without any money invested in tooling and prototypes. Simple models can be free and instantaneous, but complicated models, like those describing the mechanics of living tissue, can require years to develop, and the actual computation can be very processor intensive, requiring powerful computers and a lot of cycle time.

Subdisciplines

The field of mechanical engineering can be thought of as a collection of many mechanical disciplines. Several of these subdisciplines which are typically taught at the undergraduate level are listed below, with a brief explanation and the most common application of each. Some of these subdisciplines are unique to mechanical engineering, while others are a combination of mechanical engineering and one or more other disciplines. Most work that a mechanical engineer does uses skills and techniques from several of these subdisciplines, as well as specialized subdisciplines. Specialized subdisciplines, as used in this article, are usually the subject of graduate studies or on-the-job training more than undergraduate research. Several specialized subdisciplines are discussed at the end of this section.

Mechanics

- See main article on Mechanics

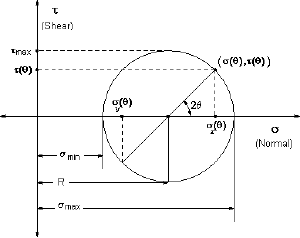

Mechanics is, in the most general sense, the study of forces and their effect upon matter. Typically, engineering mechanics is used to analyze and predict the acceleration and deformation (both elastic and plastic) of objects under known forces (also called loads) or stresses. Subdisciplines of mechanics include

- Statics, the study of non-moving bodies under known loads

- Dynamics (or kinetics), the study of how forces affect moving bodies

- Mechanics of materials, the study of how different materials deform under various types of stress

- Fluid Mechanics, the study of how fluids react to forces. Fluid mechanics can be further split into fluid statics and fluid dynamics, and is itself a subdiscipline of continuum mechanics. The application of fluid mechanics in engineering is called hydraulics.

- Continuum mechanics is a method of applying mechanics that assumes that objects are continuous. It is contrasted by discrete mechanics.

Mechanical engineers typically use mechanics in the design or analysis phases of engineering. If the engineering project were the design of a vehicle, statics might be employed to design the frame of the vehicle, in order to evaluate where the stresses will be most intense. Dynamics might be used when designing the car's engine, to evaluate the forces in the pistons and cams as the engine cycles. Mechanics of materials might be used to choose appropriate materials for the frame and engine. Fluid mechanics might be used to design a ventilation system for the vehicle (see HVAC), or to design the intake system for the engine.

Kinematics

Kinematics is the study of the motion of bodies (objects) and systems (groups of objects), while ignoring the forces that cause the motion. The movement of a crane and the oscillations of a piston in an engine are both simple kinematic systems. The crane is a type of open kinematic chain, while the piston is part of a closed four bar linkage.

Mechanical engineers typically use kinematics in the design and analysis of mechanisms. Kinematics can be used to find the possible range of motion for a given mechanism, or, working in reverse, can be used to design a mechanism that has a desired range of motion.

Mechatronics and robotics

Mechatronics is an interdisciplinary branch of mechanical engineering, electrical engineering and software engineering that is concerned with integrating electrical and mechanical engineering to create hybrid systems. In this way, machines can be automated through the use of electric motors, servo-mechanisms, and other electrical systems in conjunction with special software. A common example of a mechatronics system is a CD-ROM drive. Mechanical systems open and close the drive, spin the CD and move the laser, while an optical system reads the data on the CD and converts it to bits. Integrated software controls the process and communicates the contents of the CD to the computer.

Mechatronics is currently used in the following areas of engineering:

- Automation, and robotics.

- Servo-Mechanics

- Sensing and Control Systems

- Automotive engineering, in the design of subsystems such as anti-lock braking systems, as well as engine design, gear design, and other moving parts.

- Computer engineering, in the design of mechanisms such as hard drives, CD-ROM drives, etc.

Robotics is the application of mechatronics to create robots, which perform tasks that are dangerous, unpleasant, or repetitive. These robots may be of any shape and size, but all are preprogrammed and interact physically with the world. To create a robot, an engineer typically employs kinematics (to determine the robot's range of motion) and mechanics (to determine the stresses within the robot).

Robots are used extensively in Industrial engineering. They allow businesses to save money on labor and perform tasks that are either too dangerous or too precise for humans to perform them economically. Many companies employ assembly lines of robots, and some factories are so roboticized that they can run by themselves. Outside the factory, robots have been employed in bomb disposal, space exploration, and many other fields. Robots are also sold for various residential applications.

Structural analysis

Structural analysis is the branch of mechanical engineering devoted to examining why and how objects fail. Structural failures occur in two general modes: static failure, and fatigue failure. Static structural failure occurs when, upon being loaded (having a force applied) the object being analyzed either breaks or is deformed plastically, depending on the criterion for failure. Fatigue failure occurs when an object fails after a number of repeated loading and unloading cycles. Fatigue failure occurs because of imperfections in the object: a microscopic crack on the surface of the object, for instance, will grow slightly with each cycle (propagation) until the crack is large enough to cause failure.

Failure is not simply defined as when a part breaks, however; it is defined as when a part does not operate as intended. Some systems, such as the perforated top sections of some plastic bags, are designed to break. If these systems do not break, failure analysis might be employed to determine the cause.

Structural analysis is often used by mechanical engineers after a failure has occurred, or when designing to prevent failure. Engineers may use various books and handbooks such as those published by ASM [1] to aid them in determining the type of failure and possible causes.

Structural analysis may be used the office when designing parts, in the field to analyze failed parts, or in laboratories where parts might undergo controlled failure tests.

Thermodynamics

Thermodynamics is an applied science used in several branches of engineering, including Mechanical and Chemical Engineering. At its simplest, thermodynamics is the study of energy, its use, and its transformation through a system. Typically, engineering thermodynamics is concerned with changing energy from one form to another. As an example, automotive engines convert chemical energy (enthalpy) from the fuel into heat, and then into mechanical work that eventually turns the wheels.

Thermodynamic principles are used by mechanical engineers in the fields of heat transfer, thermofluids, and energy conversion. Mechanical engineers consider thermodynamics in the design of engines and power plants, heating, ventilation, and air-conditioning (HVAC) systems, heat exchangers, heat sinks, radiators, refrigeration, insulation, and other applications that require the movement of energy, work, or the conversion of one into the other.

Drafting

Drafting or technical drawing is the means by which mechanical engineers create instructions for manufacturing parts. A technical drawing can be a computer model or hand-drawn schematic showing all the dimensions necessary to manufacture a part, as well as assembly notes, a list of required materials, and other pertinent information. A U.S. mechanical engineer or skilled worker who creates technical drawings may be referred to as a drafter or draftsman. Drafting has historically been a two-dimensional process, but recent Computer-Aided Designing (CAD) programs have begun to allow the designer to create in three dimensions.

Instructions for manufacturing a part must be fed to the necessary machinery, either manually, through programmed instructions, or through the use of a Computer-Aided Manufacturing (CAM) or combined CAD/CAM program. Optionally, an engineer may also have a part manually manufactured using the technical drawings, but this is becoming an increasing rarity, except in the areas of applied spray coatings, finishes, and other processes that cannot economically be done by a machine.

Drafting is used in nearly every subdiscipline of mechanical engineering, and by many other branches of engineering and architecture. Three-dimensional models created using CAD software are also commonly used in Finite element analysis (FEA) and Computational fluid dynamics (CFD).

List of interdisciplinary subdisciplines

The following is a list of some additional subdisciplines and topics within mechanical engineering. These topics may be considered specialized because they are not typically part of undergraduate mechanical engineering requirements, or require training beyond an undergraduate level to be useful.

- Acoustical engineering

- Aerospace engineering

- Alternative energy

- Automotive engineering

- Biomedical engineering

- Computer-aided engineering

- Heating, ventilation, and air conditioning (HVAC)

- Nanotechnology

- Nuclear engineering

- Piping

- Power generation

- Engineering-based programming

Frontiers of Research in Mechanical Engineering

Mechanical engineering is not a static field of engineering. Mechanical engineers are constantly pushing the boundaries of what is physically possible in order to produce safer, cheaper, and more efficient machines and mechanical systems. Some technologies at the cutting edge of mechanical engineering are listed below (see also exploratory engineering).

Mechatronics

Biomechanics

See also

- List of mechanical engineering topics

- Mechanical engineering technology

- Fields of engineering

- Simple machine

- List of mechanical engineers

- List of inventors

- Patent

Notes

- ↑ ABET searchable database of accredited engineering programs, Accessed June 19, 2006

- ↑ Accredited engineering programs in Canada by the Canadian Council of Professional Engineers, Accessed April 18, 2007

- ↑ Types of post-graduate degrees offered at MIT - Accessed 19 June 2006

- ↑ University of Tulsa Required ME Courses - http://www.me.utulsa.edu/Undergraduate.html - Accessed 19 June 2006

- ↑ Harvard Mechanical Engineering Page - Accessed 19 June 2006

- ↑ MIT Engineering Electives - Accessed 19 June 2006

- ↑ Engineering article on Wikipedia

- ↑ Why Should You Get Licensed?. National Society of Professional Engineers. Retrieved July 11, 2005.

- ↑ Engineers Act. Quebec Statutes and Regulations (CanLII). Retrieved July 24, 2005.

- ↑ Codes of Ethics and Conduct. Online Ethics Center. Retrieved July 24, 2005.

- ↑ U.S. Department of Labor, Bureau of Labor Statistics, Engineering - http://www.bls.gov/oco/ocos027.htm#earnings - Accessed 19 June 2006

- ↑ http://www.worldwidelearn.com/online-education-guide/engineering/mechanical-engineering-major.htm - Website cites NACE and Dept. of Labor as sources, but was unable to verify. Accessed 19 June 2006

- ↑ http://www.jobfutures.ca/noc/2132p4.shtml - Accessed June 19, 2006

Related journals

- Experimental Heat Transfer[2]

- Heat Transfer Engineering[3]

- International Journal for Computational Methods in Engineering Science and Mechanics [4]

- International Journal of Optomechatronics[5]

- Machining Science and Technology[6]

- Materials and Manufacturing Processes[7]

- Mechanics Based Design of Structures and Machines[8]

- Mechanics of Advanced Materials and Structures[9]

- Nanoscale and Microscale Thermophysical Engineering[10]

- Numerical Heat Transfer, Part A[11]

- Numerical Heat Transfer, Part B[12]

- Tribology Transactions[13]

- Journal of Fluids Engineering[14]

ReferencesISBN links support NWE through referral fees

<<We need at least 3 reliable references here, formatted according to our guidelines.>>

- Burstall, Aubrey F. (1965). A History of Mechanical Engineering. The MIT Press. ISBN 0-262-52001-X.

External links

<<It would be useful to include some relevant Web sites.>>

- Mechanical Engineering Articles - http://www.mechanicalengineering.cc - Mechanical Engineering Knowledge Base. Accessed June 16, 2007 .

| ||||||||||||||||||||||||||

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.