Difference between revisions of "Silk" - New World Encyclopedia

m (Unlink unwanted links) |

Rick Swarts (talk | contribs) (added updated Wikipedia version) |

||

| Line 1: | Line 1: | ||

{{ready}}{{images OK}} | {{ready}}{{images OK}} | ||

| − | + | {{About|a natural [[fibre]] and the [[textile]] woven from it|other uses|Silk (disambiguation)}} | |

| − | |||

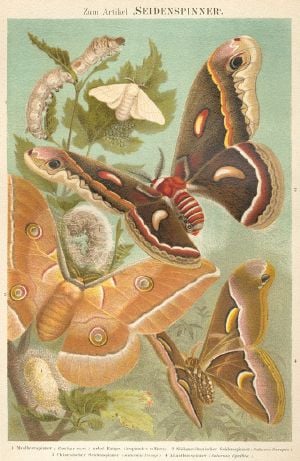

| − | + | [[File:Meyers b14 s0826a.jpg|thumb|Four of the most important domesticated silk worms, together with their adult moth forms, [[Meyers Konversations-Lexikon]] (1885-1892)]] | |

| − | + | '''Silk''' is a natural [[protein]] [[fibre]], some forms of which can be [[weaving|woven]] into [[textile]]s. The best-known type of silk is obtained from the [[Pupa#Cocoon|cocoon]]s of the [[larva]]e of the [[mulberry]] [[silkworm]] ''[[Bombyx mori]]'' reared in captivity ([[sericulture]]). The shimmering appearance of silk is due to the triangular [[prism (optics)|prism]]-like structure of the silk fibre, which allows silk cloth to refract incoming light at different [[angle]]s, thus producing different colors. | |

| − | |||

| − | Silks are produced by several other insects, but only the silk of moth caterpillars has been used for textile | + | Silks are produced by several other insects, but only the silk of moth caterpillars has been used for textile manufacturing. There has been some research into other silks, which differ at the molecular level. Silks are mainly produced by the [[larva]]e of insects undergoing [[Holometabolism|complete metamorphosis]], but also by some adult insects such as [[webspinner]]s. Silk production is especially common in the [[Hymenoptera]] ([[bee]]s, [[wasp]]s, and [[ant]]s), and is sometimes used in nest construction. Other types of [[arthropod]] produce silk, most notably various [[arachnid]]s such as [[spider]]s (see [[spider silk]]). |

| − | ==History of silk | + | ==History== |

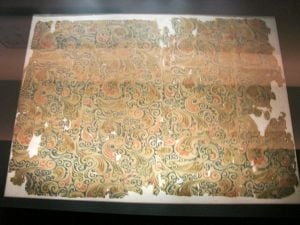

| − | {{ | + | [[File:Silk from Mawangdui 2.jpg|thumb|right|Woven silk textile from tomb no 1. at [[Mawangdui]] in [[Changsha]], [[Hunan]] province, [[China]], from the [[Western Han Dynasty]], 2nd century B.C.E.]] |

| + | [[File:Landscape of quick water from high mountain by Zhao Zuo.jpg|thumb|100px|right|''Landscape of quick water from high mountain'' by Zhao Zho, [[Ming Dynasty]], 1611 C.E. Hand scroll, ink and colour on silk.]] | ||

| + | {{Main|History of silk}} | ||

| + | |||

| + | ===Wild silk=== | ||

| + | A variety of [[wild silk]]s, produced by [[caterpillar]]s other than the mulberry silkworm have been known and used in [[China]], [[South Asia]], and [[Europe]] since ancient times. However, the scale of production was always far smaller than that of cultivated silks. They differ from the domesticated varieties in color and [[wikt:texture|texture]], and cocoons gathered in the wild usually have been damaged by the emerging moth before the cocoons are gathered, so the silk thread that makes up the cocoon has been torn into shorter lengths. Commercially reared silkworm pupae are killed by dipping them in boiling water before the adult moths emerge, or by piercing them with a needle, allowing the whole cocoon to be unraveled as one continuous thread. This permits a much stronger cloth to be woven from the silk. Wild silks also tend to be more difficult to dye than silk from the cultivated silkworm. | ||

===China=== | ===China=== | ||

| − | + | Silk fabric was first developed in ancient [[China]],<ref>{{Cite web|url=http://www.infoplease.com/ce6/society/A0861091.html|title=Silk: History|publisher=''[[Columbia Encyclopedia]]'' Sixth Edition}}</ref> with some of the earliest examples found as early as 3500 B.C.E..<ref>{{Cite web|url=http://www.asianart.com/textiles/intro.html|title=Textile Exhibition: Introduction|publisher=Asian art}}</ref> Legend gives credit for developing silk to a Chinese empress, [[Lei Zu]] (Hsi-Ling-Shih, Lei-Tzu). Silks were originally reserved for the Kings of China for their own use and gifts to others, but spread gradually through [[Chinese culture]] and trade both geographically and socially, and then to many regions of [[Asia]]. Silk rapidly became a popular luxury fabric in the many areas accessible to Chinese merchants because of its texture and luster. Silk was in great demand, and became a staple of pre-[[industrial revolution|industrial]] international [[trade]]. In July 2007, archeologists discovered intricately woven and dyed silk [[textile]]s in a tomb in [[Jiangxi]] province, dated to the Eastern [[Zhou Dynasty]] roughly 2,500 years ago.<ref name="people's daily">{{Cite web|url= http://english.people.com.cn/90001/90782/6228297.html | title = Chinese archaeologists make ground-breaking textile discovery in 2,500-year-old tomb | accessdate = 2007-08-26 | work = | publisher = People's Daily Online.}}</ref> Although historians have suspected a long history of a formative textile industry in ancient China, this find of silk textiles employing "complicated techniques" of weaving and dyeing provides direct and concrete evidence for silks dating before the [[Mawangdui]]-discovery and other silks dating to the [[Han Dynasty]] (202 BC-220 AD).<ref name="people's daily"/> | |

| − | Silk fabric was first developed in ancient [[China]], | ||

| − | The first evidence of the silk trade is the finding of silk in the hair of an [[Egypt]]ian [[mummy]] of the 21st dynasty, c.1070 | + | The first evidence of the silk trade is the finding of silk in the hair of an [[Egypt]]ian [[mummy]] of the 21st dynasty, c.1070 BC.<ref>{{Cite journal |

| + | | unused_data = DUPLICATE DATA: doi = 10.1038/362025b0 | ||

| + | | doi = 10.1038/362025b0 | ||

| + | | volume = 362 | ||

| + | | issue = 6415 | ||

| + | | pages = 25 | ||

| + | | last = Lubec | ||

| + | | first = G. | ||

| + | | coauthors = J. Holaubek, C. Feldl, B. Lubec, E. Strouhal | ||

| + | | title = Use of silk in ancient Egypt | ||

| + | | journal = Nature | ||

| + | | accessdate = 2010-07-24 | ||

| + | | date = 1993-03-04 | ||

| + | }} (also available [http://www.silk-road.com/artl/egyptsilk.shtml here])</ref> Ultimately the silk trade reached as far as the [[India]]n subcontinent, the [[Middle East]], [[Europe]], and [[North Africa]]. This trade was so extensive that the major set of trade routes between Europe and Asia has become known as the [[Silk Road]]. The highest development was in China. | ||

| − | The [[Emperors of China]] strove to keep knowledge of sericulture secret to maintain the Chinese [[monopoly]]. Nonetheless sericulture reached [[Korea]] around 200 | + | The [[Emperors of China]] strove to keep knowledge of [[sericulture]] secret to maintain the Chinese [[monopoly]]. Nonetheless sericulture reached [[Korea]] around 200 BC, about the first half of the 1st century AD had reached ancient [[Khotan]],<ref>Hill, John E. 2003. "Annotated Translation of the Chapter on the Western Regions according to the ''Hou Hanshu''." 2nd Draft Edition. Appendix A. [http://depts.washington.edu/silkroad/texts/hhshu/hou_han_shu.html#a]</ref> and by AD 300 the practice had been established in India.{{Citation needed|date=July 2009}} |

===Thailand=== | ===Thailand=== | ||

| − | + | {{Main|Thai silk}} | |

| − | + | Silk is produced, year round, in Thailand by two types of silkworms, the cultured Bombycidae and wild Saturniidae. Most production is after the rice harvest in the southern and northeast parts of the country. Women traditionally weave silk on hand looms, and pass the skill on to their daughters as weaving is considered to be a sign of maturity and eligibility for marriage. Thai silk textiles often use complicated patterns in various colours and styles. Most regions of Thailand have their own typical silks. A single thread [[fiber|filament]] is too thin to use on its own so women combine many threads to produce a thicker, usable fibre. They do this by hand-reeling the threads onto a wooden spindle to produce a uniform strand of raw silk. The process takes around 40 hours to produce a half kilogram of Thai silk. | |

| − | Silk, | ||

| − | + | Many local operations use a reeling machine for this task, but some silk threads are still hand-reeled. The difference is that hand-reeled threads produce three grades of silk: two fine grades that are ideal for lightweight fabrics, and a thick grade for heavier material. | |

| − | |||

| − | |||

| − | + | The silk fabric is soaked in extremely cold water and bleached before dyeing to remove the natural yellow coloring of Thai silk yarn. To do this, skeins of silk thread are immersed in large tubs of hydrogen peroxide. Once washed and dried, the silk is woven on a traditional hand operated loom.<ref>[http://www.bangkok-thailand.com/about-thai-silk.htm About Thai silk] from World of Thai Silk (commercial)</ref> | |

| − | + | [[File:Khmersilk.JPG|thumb|Woven silk from [[Cambodia]]]] | |

| − | |||

| − | |||

| − | [[ | ||

| − | Silk | + | ===India=== |

| + | Silk, known as "Paat" in Eastern India, ''Pattu'' in southern parts of [[India]] and ''Resham'' in Hindi/Urdu, has a long history in India. Recent archaeological discoveries in [[Harappa]] and [[Chanhu-daro]] suggest that [[sericulture]], employing [[wild silk]] threads from native [[silkworm]] species, existed in [[South Asia]] during the time of the [[Indus Valley Civilization]], roughly contemporaneous with the earliest known silk use in China.<ref>{{Cite journal| last1=Good | first1=I.L. | last2=Kenoyer | first2=J.M. | last3=Meadow | first3=R.H. | title=New evidence for early silk in the Indus civilization | journal=Archaeometry | volume=50 | pages=457 | year=2009 | doi=10.1111/j.1475-4754.2008.00454.x }}</ref> Silk is widely produced today. India is the second largest producer of silk after China. A majority of the silk in India is produced in [[Karnataka]] State, particularly in [[Mysore]] and the North Bangalore regions of [[Muddenahalli]], [[Kanivenarayanapura]], and [[Doddaballapur]].<ref>[http://www.deccanherald.com/content/31009/silk-city-come-up-near.html Silk city to come up near B’lore], ''[[Deccan Herald]]'', 16 October 2009.</ref> India is also the largest consumer of silk in the world. The tradition of wearing silk sarees in marriages by the brides is followed in southern parts of India. Silk is worn by people as a symbol of royalty while attending functions and during festivals. Historically silk was used by the upper classes, while cotton was used by the poorer classes. Today silk is mainly produced in [[Bhoodhan Pochampally]] (also known as [[Silk City]]), [[Kanchipuram]], Dharmavaram, Mysore, etc. in South India and [[Banaras]] in the North for manufacturing [[garments]] and [[saree]]s. "Murshidabad silk", famous from historical times, is mainly produced in Malda and Murshidabad district of West Bengal and woven with hand looms in Birbhum and Murshidabad district. Another place famous for production of silk is [[Bhagalpur]]. The silk from [[Pochampally]] is particularly well-known for its classic designs and enduring quality. The silk is traditionally hand-woven and hand-dyed and usually also has silver threads woven into the cloth. Most of this silk is used to make sarees. The sarees usually are very expensive and vibrant in color. Garments made from silk form an integral part of Indian weddings and other celebrations. In the northeastern state of [[Assam]], three different types of silk are produced, collectively called [[Assam silk]]: Muga, Eri and Pat silk. Muga, the golden silk, and Eri are produced by silkworms that are native only to Assam. The heritage of silk rearing and weaving is very old and continues today especially with the production of Muga and Pat ''riha'' and ''[[mekhela chador]]'', the three-piece silk [[saree]]s woven with traditional motifs. ''Mysore Silk Sarees'', which are known for their soft texture, last many years if carefully maintained. | ||

| − | === | + | ===Ancient Mediterranean=== |

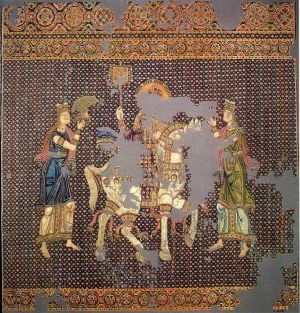

| − | [[ | + | [[File:Gunthertuch.jpg|thumb|right|The ''[[Gunthertuch]]'', an 11th-century silk celebrating a [[Byzantine emperor]]'s triumph]] |

| + | In the [[Odyssey]], 19.233, when Odysseus, while pretending to be someone else, is questioned by Penelope about her husband's clothing, he says that he wore a shirt "gleaming like the skin of a dried onion" (varies with translations, literal translation here)<ref>[[Odyssey]] '''19''' 233-234: | ||

| + | τὸν δὲ χιτῶν' ἐνόησα περὶ χροῒ σιγαλόεντα, οἷόν τε κρομύοιο λοπὸν κάτα ἰσχαλέοιο· = "And I [= [[Odysseus]]</ref> which could refer to the lustrous quality of silk fabric. The [[Roman Empire]] knew of and traded in silk. During the reign of emperor [[Tiberius]], [[sumptuary laws]] were passed that forbade men from wearing silk garments, but these proved ineffectual.<ref>{{Cite book | ||

| + | | last = Tacitus | ||

| + | | authorlink =Tacitus | ||

| + | | title =Annals | ||

| + | | url =http://www.gutenberg.org/etext/7959 | ||

| + | | isbn = 0521315433}}</ref> | ||

| + | Despite the popularity of silk, the secret of silk-making only reached Europe around AD 550, via the [[Byzantine Empire]]. Legend has it that monks working for the emperor [[Justinian I]] smuggled silkworm eggs to [[Constantinople]] in hollow canes from China. All top-quality looms and weavers were located inside the Palace complex in [[Constantinople]] and the cloth produced was used in imperial robes or in diplomacy, as gifts to foreign dignitaries. The remainder was sold at very high prices. | ||

| − | [[ | + | ===Middle East=== |

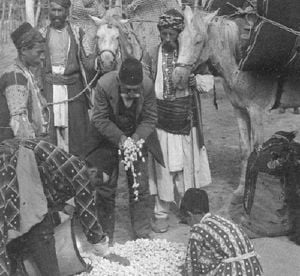

| + | [[File:Silkworm Cocoon purchasing in Antioch.jpg|thumb|right|Purchasing silkworm cocoons in [[Antioch]], circa 1895.]] | ||

| + | [[File:Vestido Javiera Carrera.jpg|thumb|Dress made from silk]] | ||

| + | In [[Islamic]] teachings, Muslim men are forbidden to wear silk. Many religious jurists believe the reasoning behind the prohibition lies in avoiding clothing for men that can be considered feminine or extravagant.<ref>{{Cite web | ||

| + | | title = Silk: Why It Is Haram for Men | ||

| + | |date=2003-09-23 | ||

| + | | url = http://www.islamonline.net/fatwa/english/FatwaDisplay.asp?hFatwaID=61261 | ||

| + | | accessdate = 2007-01-06 |archiveurl = http://web.archive.org/web/20070302204114/http://www.islamonline.net/fatwa/english/FatwaDisplay.asp?hFatwaID=61261 <!-- Bot retrieved archive —> |archivedate = 2007-03-02}}</ref> There are disputes regarding the amount of silk a fabric can consist of (i.e., whether a small decorative silk piece on a cotton caftan is permissible or not) for it to be lawful for men to wear but the dominant opinion of most Muslim scholars is that the wearing of silk for men is forbidden. | ||

| − | + | Despite injunctions against silk for men, silk has retained its popularity in the Islamic world because of its permissibility for women. The Muslim [[Moors]] brought silk with them to Spain during their conquest of the Iberian Peninsula. | |

| − | |||

| − | == | + | ===Medieval and modern Europe=== |

| − | + | [[Venice|Venetian]] merchants traded extensively in silk and encouraged silk growers to settle in [[Italy]]. By the 13th century, Italian silk was a significant source of trade. Since that period, the silk worked in the [[province of Como]] has been the most valuable silk in the world. The wealth of [[Florence]] was largely built on textiles, both [[wool]] and silk, and other cities like [[Lucca]] also grew rich on the trade. Italian silk was so popular in Europe that [[Francis I of France]] invited Armenian silk makers to France to create a French silk industry, especially in [[Lyon]]. Mass emigration (especially of [[Huguenots]]) during periods of religious dispute had seriously damaged French industry and introduced these various textile industries, including silk, to other countries. Silk was expensive in Medieval Europe and used only by the rich. Italian merchants like [[Giovanni Arnolfini]] became hugely wealthy trading it to the Courts of Northern Europe. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:56-aspetti di vita quotidiana,abbigliamento in seta,Taccuino.jpg|200px|thumb|left|Silk clothing in the [[Tacuinum Sanitatis]] (XIV century)]] | |

| − | Silk | ||

| − | + | [[James I of England|James I]] attempted to establish silk production in England, purchasing and planting 100,000 mulberry trees, some on land adjacent to [[Hampton Court Palace]], but they were of a species unsuited to the silk worms, and the attempt failed. In 1717, John Lombe, visited Piedmont and returned to England with details of the Italian machines, and some Italian craftsmen. He was granted a fourteen year patent, and built [[Lombe's Mill]] in Derby. The King of Sardinia retaliated by prohibiting the export of raw silk. Nethertheless, in 1732 John Guardivaglio set up a silk throwing enterprise at [[List of mills in Stockport|Logwood mill in Stockport]], and in 1744, Burton Mill was erected in [[Macclesfield]] and in 1753 Old Mill was built in [[Congleton]].<ref name=Callender> {{Harvnb|Callendine|1993}} </ref>. These three towns remained the centre of the English silk throwing industry until silk throwing was replaced by [[silk waste|silk waste spinning]]. British enterprise also established silk filature in [[Cyprus]] in 1928. In England in the mid 20th Century, raw silk was produced at [[Lullingstone Castle]] in Kent. Silkworms were raised and reeled under the direction of Zoe Lady Hart Dyke. Production started elsewhere later. | |

| − | |||

| − | = | + | In [[Italy]], the [[Stazione Bacologica Sperimentale]] was founded in [[Padua]] in 1871 to research sericulture. In the late 19th century, China, Japan, and Italy were the major producers of silk.<ref name=Rayner>{{Harvnb|Rayner|1903}}</ref> The most important cities for silk production in Italy were [[Como]] and [[Meldola]] <ref>[http://www.genm.it/wp-content/uploads/2008/02/museo-baco-seta-inglese.pdf The Silkworm Museum, Meldola]</ref> ([[Forlì]]). <!-- In medieval times, it was common for silk to be used to make elaborate casings for bananas and other fruits.—> |

| − | |||

| − | === | + | ===North America=== |

| − | ==== | + | [[James I of England]] introduced silk-growing to the American colonies around 1619, ostensibly to discourage [[tobacco]] planting. The [[Shakers]] in Kentucky adopted the practice as did a cottage industry in New England.<ref>{{Cite web| title=Mansfield Historical Society | url=http://www.mansfieldct-history.org/Industry/Silk/silk_production.shtml | year=2008 | accessdate=2009-03-30}} {{Dead link|date=September 2010|bot=H3llBot}}</ref> In the 19th century a new attempt at a silk industry began with European-born workers in [[Paterson, New Jersey]], and the city became a US silk center, although Japanese imports were still more important. |

| − | |||

| − | + | [[World War II]] interrupted the silk trade from [[Japan]]. Silk prices increased dramatically, and US industry began to look for substitutes, which led to the use of [[Synthetic fiber|synthetic]]s such as [[nylon]]. Synthetic silks have also been made from [[lyocell]], a type of [[cellulose]] fiber, and are often difficult to distinguish from real silk (see [[spider silk]] for more on synthetic silks). | |

| − | Silk | ||

| − | == | + | ==Properties== |

| − | + | [[File:Models by David Shankbone.jpg|280px|thumb|Models in silk dresses at the MoMo Falana fashion show]] | |

| − | === | + | ===Physical properties=== |

| + | Silk fibres from the ''Bombyx mori'' silkworm have a [[triangle|triangular]] [[Cross section (geometry)|cross section]] with rounded corners, 5-10 [[μm]] wide. The fibroin-heavy chain is composed mostly of beta-sheets, due to a 59-mer aminoacid repeat sequence with some variations.<ref>"Handbook of Fiber Chemistry", Menachem Lewin, Editor, 3rd ed., 2006, CRC press, ISBN 0-8247-2565-4</ref> The flat surfaces of the fibrils reflect [[light]] at many angles, giving silk a natural shine. The cross-section from other silkworms can vary in shape and diameter: crescent-like for ''Anaphe'' and elongated wedge for ''tussah''. Silkworm fibres are naturally extruded from two silkworm glands as a pair of primary filaments (brin), which are stuck together, with sericin proteins that act like [[glue]], to form a [[bave]]. Bave diameters for tussah silk can reach 65 μm. See cited reference for cross-sectional SEM photographs.<ref>"Handbook of Fiber Chemistry", Menachem Lewin, Editor, 2nd ed.,1998, Marcel Dekker, pp. 438-441, ISBN 0-8247-9471-0</ref> | ||

| − | + | Silk has a smooth, soft texture that is not slippery, unlike many [[synthetic fiber]]s. | |

| − | Silk | ||

| − | |||

| − | + | Silk is one of the strongest natural fibres but loses up to 20% of its strength when wet. It has a good [[moisture regain]] of 11%. Its [[Elasticity (physics)|elasticity]] is moderate to poor: if elongated even a small amount, it remains stretched. It can be weakened if exposed to too much sunlight. It may also be attacked by insects, especially if left dirty. | |

| − | Silk has a good moisture regain of 11%. | ||

| − | + | Silk is a poor conductor of [[electricity]] and thus susceptible to [[static cling]]. | |

| − | Silk is a poor conductor of electricity | ||

| − | + | Unwashed silk chiffon may shrink up to 8% due to a relaxation of the fibre macrostructure. So silk should either be pre-washed prior to garment construction, or [[Dry cleaning|dry cleaned]]. [[Dry cleaning]] may still shrink the chiffon up to 4%. Occasionally, this shrinkage can be reversed by a gentle steaming with a press cloth. There is almost no gradual shrinkage nor shrinkage due to molecular-level deformation. | |

| − | |||

| − | === | + | Natural and synthetic silk is known to manifest piezoelectric properties in proteins, probably due to its molecular structure.<ref>{{Cite web|url=http://fs.tx.ncsu.edu/Past_Meetings/Spring_2003_Loughborough/papers/081-Ellison.pdf|title=Piezoelectricity in Natural and Synthetic Silks|accessdate=28 April 2010}}</ref> |

| − | |||

| − | + | Silkworm silk was used as the standard for the [[Units_of_textile_measurement#Denier|denier]], a measurement of [[linear density]] in fibers. Silkworm silk therefore has a linear density of approximately 1 den, or 1.1 [[Units_of_textile_measurement#Tex|dtex]]. | |

| − | + | {| class="wikitable" | |

| − | + | |- | |

| + | ! Comparison of silk fibers<ref>{{Cite web|url=http://web.mit.edu/course/3/3.064/www/slides/Ko_spider_silk.pdf|title=Engineering Properties of Spider Silk|author=Frank K. Ko |coauthors=Sueo Kawabata, Mari Inoue, Masako Niwa|accessdate=9 July 2010}}</ref> !! Linear Density(dtex) !! Diameter (μm) !! Coeff. Variation | ||

| + | |- | ||

| + | | [[Moth]]: ''[[Bombyx mori]]'' || 1.17 || 12.9 || 24.8% | ||

| + | |- | ||

| + | | [[Spider]]: ''[[Argiope aurentia]]'' || 0.14 || 3.57 || 14.8% | ||

| + | |} | ||

| − | + | ===Chemical properties=== | |

| − | === | + | Silk emitted by the silkworm consists of two main proteins, [[sericin]] and [[fibroin]], fibroin being the structural center of the silk, and serecin being the sticky material surrounding it. Fibroin is made up of the [[amino acid]]s [[Glycine|Gly]]-[[Serine|Ser]]-Gly-[[Alanine|Ala]]-Gly-Ala and forms [[beta sheet|beta pleated sheet]]s. [[Hydrogen bond]]s form between chains, and side chains form above and below the plane of the hydrogen bond network. |

| − | Silk | ||

| − | + | The high proportion (50%) of glycine, which is a small [[amino acid]], allows tight packing and the fibers are strong and resistant to breaking. The tensile strength is due to the many interseeded hydrogen bonds, and when stretched the force is applied to these numerous bonds and they do not break. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Silk is resistant to most [[mineral acid]]s, except for [[sulfuric acid]], which dissolves it. It is yellowed by perspiration. | |

| − | Silk | ||

| − | == | + | ==Uses== |

| − | + | [[File:Turkeye.Urgüp02.jpg|200px|thumb||Silk filaments being unraveled from silk cocoons, [[Cappadocia]], [[Turkey]], 2007.]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Silk's [[absorption (chemistry)|absorbency]] makes it comfortable to wear in warm weather and while active. Its low conductivity keeps warm air close to the skin during cold weather. It is often used for clothing such as [[shirt]]s, [[necktie|ties]], [[blouse]]s, formal [[dress]]es, high fashion clothes, [[lingerie]], [[pyjama]]s, [[robe]]s, dress [[suit]]s, sun dresses and [[kimono]]s. | |

| − | |||

| − | [[ | + | Silk's attractive luster and drape makes it suitable for many [[furnishing]] applications. It is used for [[upholstery]], wall coverings, window treatments (if blended with another fiber), [[Carpet|rug]]s, [[bedding]] and wall hangings.{{Citation needed|date=March 2009}} |

| − | + | While on the decline now, due to artificial fibers, silk has had many industrial and commercial uses; [[parachute]]s, bicycle [[tire]]s, [[silk comforter|comforter filling]] and [[artillery]] [[gunpowder]] bags.{{Citation needed|date=March 2009}} | |

| − | + | A special manufacturing process removes the outer irritant sericin coating of the silk, which makes it suitable as non-absorbable [[surgical suture]]s. This process has also recently led to the introduction of specialist silk underclothing for children and adults with [[eczema]] where it can significantly reduce [[itch]].{{Citation needed|date=March 2009}} | |

| − | |||

| − | ==Production | + | ==Production== |

| − | + | The cultivation of silk is called [[sericulture]]. Over 30 countries produce silk, the major ones are [[China]] (54%) and [[India]] (14%). | |

| − | + | <blockquote><p>To produce 1 kg of silk, 104 kg of mulberry leaves must be eaten by 3000 silkworms. It takes about 5000 silkworms to make a pure silk [[kimono]].<ref>Fritz, Anne and Cant, Jennifer (1986). ''Consumer Textiles''. [[Oxford University Press]] Australia. Reprint 1987. ISBN 0 19 554647 4.</ref>{{Rp|104}}</p></blockquote> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | === | + | {| border="1" cellpadding="3" cellspacing="0" width="100%" class="wikitable" align=left style="clear:left" |

| − | # | + | ! colspan=5|Top Ten Cocoons (Reelable) Producers — 2005 |

| − | # | + | |- |

| − | # | + | ! bgcolor="#DDDDFF" width="30%" | Country |

| − | + | ! bgcolor="#DDDDFF" width="25%" | Production {{nowrap|(Int $1000)}} | |

| − | + | ! bgcolor="#DDDDFF" width="10%" | Footnote | |

| − | + | ! bgcolor="#DDDDFF" width="25%" | Production {{nowrap|(1000 kg)}} | |

| − | + | ! bgcolor="#DDDDFF" width="10%" | Footnote | |

| − | * | + | |- |

| − | + | | {{PRC}} || 978,013 || C || 290,003 || F | |

| + | |- | ||

| + | | {{IND}} || 259,679 || C || 77,000 || F | ||

| + | |- | ||

| + | | {{UZB}} || 57,332 || C || 17,000 || F | ||

| + | |- | ||

| + | | {{BRA}} || 37,097 || C || 11,000 || F | ||

| + | |- | ||

| + | | {{IRN}} || 20,235 || C || 6,000 || F | ||

| + | |- | ||

| + | | {{THA}} || 16,862 || C || 5,000 || F | ||

| + | |- | ||

| + | | {{VNM}} || 10,117 || C || 3,000 || F | ||

| + | |- | ||

| + | | {{DPRK}} || 5,059 || C || 1,500 || F | ||

| + | |- | ||

| + | | {{ROU}} || 3,372 || C || 1,000 || F | ||

| + | |- | ||

| + | | {{JPN}} || 2,023 || C || 600 || F | ||

| + | |- | ||

| + | |colspan=5 style="font-size:.7em"|No symbol = official figure, F = FAO estimate, * = Unofficial figure, C = Calculated figure;<br> | ||

| + | Production in Int $1000 have been calculated based on 1999-2001 international prices<br> | ||

| + | Source: [http://www.fao.org/es/ess/top/commodity.html?lang=en&item=1185&year=2005 Food And Agricultural Organization of United Nations: Economic And Social Department: The Statistical Division] | ||

| + | |} | ||

| + | {{-}} | ||

| − | + | ===Cultivation=== | |

| + | [[File:Bombyx mori Cocon 02.jpg|thumb|[[Pupa#Cocoon|Cocoon]]]] | ||

| + | Silk moths lay eggs on specially prepared paper. The eggs hatch and the caterpillars (silkworms) are fed fresh mulberry leaves. After about 35 days and 4 moltings, the caterpillars are 10,000 times heavier than when hatched and are ready to begin spinning a cocoon. A straw frame is placed over the tray of caterpillars, and each caterpillar begins spinning a cocoon by moving its head in a "figure 8" pattern. Two glands produce liquid silk and force it through openings in the head called spinnerets. Liquid silk is coated in sericin, a water-soluble protective gum, and solidifies on contact with the air. Within 2–3 days, the caterpillar spins about 1 mile of filament and is completely encased in a cocoon. The silk farmers then kill most caterpillars by heat, leaving some to [[metamorphosis|metamorphose]] into moths to breed the next generation of caterpillars. | ||

| − | ''' | + | Harvested cocoons are then soaked in boiling water to soften the sericin holding the silk fibers together in a cocoon shape. The fibers are then unwound to produce a continuous thread. Since a single thread is too fine and fragile for commercial use, anywhere from three to ten strands are spun together to form a single thread of silk.<ref>Carrie Gleason: ''The Biography of Silk'', page 12. Crabtree Publishing Company 2007.</ref> |

| − | < | + | ==Animal rights== |

| − | + | As the process of harvesting the silk from the cocoon kills the larvae, sericulture has been criticized in the early 21st century by [[animal rights]] activists, especially since [[artificial silk]]s are available.<ref>{{Cite web | |

| − | + | | title = Down and Silk: Birds and Insects Exploited for Fabric | |

| − | + | | publisher =[[PETA]] | |

| − | </ | + | | url = http://www.peta.org/mc/factsheet_display.asp?ID=121 |

| − | + | | accessdate = 2007-01-06 }}</ref> | |

| − | + | [[Mohandas Karamchand Gandhi|Mohandas Gandhi]] was also critical of silk production based on the [[Ahimsa]] philosophy "not to hurt any living thing." This led to Gandhi's promotion of cotton spinning machines, an example of which can be seen at the Gandhi Institute. He also promoted ''[[Ahimsa silk]]'', [[wild silk]] made from the cocoons of wild and semi-wild silk moths.<ref>"Mahatma Gandhi: 100 years", 1968, [http://books.google.com/books?id=LGVuAAAAMAAJ&q=%22ahimsa+silk%22&dq=%22ahimsa+silk%22 p. 349]</ref> Ahimsa silk is promoted in parts of Southern India for those who prefer not to wear silk produced by killing silkworms.<ref>[http://www.actionagainstpoisoning.com/NEWSACTIONREQUEST/page233/NewssilkMothsflyfree.html Silk Moths Fly Free] Kusuma Rajaiah's Ahimsa project.</ref><ref>[http://www.thebetterindia.com/135/ahimsa-silk-silk-saree-without-killing-a-single-silkworm/ Silk saree without killing a single silkworm] Another article about Rajaiah and his methods.</ref> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | = | ||

| − | |||

| − | |||

| − | |||

| − | |||

==See also== | ==See also== | ||

| − | + | * [[Art silk]] | |

| + | * [[Byzantine silk]] | ||

| + | * [[History of silk]] | ||

| + | * [[International Year of Natural Fibres]] 2009 | ||

* [[Mommes]], the traditional density unit for silk. | * [[Mommes]], the traditional density unit for silk. | ||

* [[Rayon]] | * [[Rayon]] | ||

| − | * [[ | + | * [[Silk in the Indian subcontinent]] |

* [[Silk Road]] | * [[Silk Road]] | ||

| + | * [[Silk waste]] | ||

* [[Spider silk]] (with a discussion of synthetic silk) | * [[Spider silk]] (with a discussion of synthetic silk) | ||

* [[Tenun Pahang Diraja]], famous woven silk fabric of [[Pahang]], [[Malaysia]]. | * [[Tenun Pahang Diraja]], famous woven silk fabric of [[Pahang]], [[Malaysia]]. | ||

| − | * [[ | + | * [[Thai silk]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==References== | ==References== | ||

| − | * | + | ;Notes |

| − | * [http://depts.washington.edu/silkroad/texts/weilue/weilue.html The Peoples of the West from the | + | {{Reflist}} |

| − | * | + | ;Bibliography |

| − | * | + | * {{cite journal|last=Callandine|first=Anthony|year=1993|title=Lombe's Mill: An Exercise in reconstruction|journal=Industrial Archaelogy Review|publisher=Maney Publishing|volume=XVI|issue=1|issn=0309-0728}} |

| + | * Good, Irene. 1995. “On the question of silk in pre-Han Eurasia” ''Antiquity'' Vol. 69, Number 266, December 1995, pp. 959–968 | ||

| + | * Hill, John E. 2004. [http://depts.washington.edu/silkroad/texts/weilue/weilue.html ''The Peoples of the West from the Weilüe''] 魏略 ''by Yu Huan'' 魚豢'': A Third Century Chinese Account Composed between 239 and 265 C.E.'' Draft annotated English translation. Appendix E. | ||

| + | * Kuhn, Dieter. 1995. “Silk Weaving in Ancient China: From Geometric Figures to Patterns of Pictorial Likeness.” ''Chinese Science'' 12 (1995): pp. 77–114. | ||

| + | * [[Xinru Liu|Liu, Xinru]] (1996). ''Silk and Religion: An Exploration of Material Life and the Thought of People, AD 600-1200''. Oxford University Press. | ||

| + | * [[Xinru Liu|Liu, Xinru]] (2010). ''The Silk Road in World History''. Oxford University Press. ISBN 978-0-19-516174-8; ISBN 978-0-19-533810-2 (pbk). | ||

| + | * {{cite book|last=Rayner|first=Hollins|title=Silk throwing and waste silk spinning |url=http://openlibrary.org/books/OL7174062M/Silk_throwing_and_waste_silk_spinning|year=1903|publisher=Scott, Greenwood, Van Nostrand}} | ||

* Sung, Ying-Hsing. 1637. ''Chinese Technology in the Seventeenth Century - T'ien-kung K'ai-wu''. Translated and annotated by E-tu Zen Sun and Shiou-chuan Sun. Pennsylvania State University Press, 1966. Reprint: Dover, 1997. Chap. 2. Clothing materials. | * Sung, Ying-Hsing. 1637. ''Chinese Technology in the Seventeenth Century - T'ien-kung K'ai-wu''. Translated and annotated by E-tu Zen Sun and Shiou-chuan Sun. Pennsylvania State University Press, 1966. Reprint: Dover, 1997. Chap. 2. Clothing materials. | ||

| − | * Kadolph, Sara J. | + | * Kadolph, Sara J. Textiles. 10th ed. Upper Saddle River: Pearson Prentice Hall, 2007. 76-81. |

| + | |||

| + | ==External links== | ||

| + | {{Wiktionary}} | ||

| + | {{Commons category|Silk}} | ||

| + | * [http://penelope.uchicago.edu/Thayer/E/Roman/Texts/secondary/SMIGRA*/Sericum.html References to silk by Roman and Byzantine writers] | ||

| + | * [http://www.geospace.co.uk/silk/worldsilk.html A series of maps depicting the global trade in silk] | ||

| + | * [http://www.gather.com/viewArticle.jsp?articleId=281474977152137 History of traditional silk in martial arts uniforms] | ||

| + | * [http://www.suekayton.com/silk.htm Raising silkworms in classrooms for educational purposes (with photos)] | ||

| + | * [http://www.physorg.com/news171790220.html New thread in fabric of insect silks | physorg.com] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{{fibers}} | {{fibers}} | ||

| + | {{fabric}} | ||

| + | {{Clothing}} | ||

| + | {{Use dmy dates|date=September 2010}} | ||

| + | |||

| + | [[Category:Silk| ]] | ||

| + | [[Category:Fibers]] | ||

| + | [[Category:Woven fabrics]] | ||

| + | |||

[[Category:Life sciences]] | [[Category:Life sciences]] | ||

| − | {{credits| | + | {{credits|412989843}} |

Revision as of 00:49, 11 February 2011

- This article is about a natural fibre and the textile woven from it. For other uses, see Silk (disambiguation).

Silk is a natural protein fibre, some forms of which can be woven into textiles. The best-known type of silk is obtained from the cocoons of the larvae of the mulberry silkworm Bombyx mori reared in captivity (sericulture). The shimmering appearance of silk is due to the triangular prism-like structure of the silk fibre, which allows silk cloth to refract incoming light at different angles, thus producing different colors.

Silks are produced by several other insects, but only the silk of moth caterpillars has been used for textile manufacturing. There has been some research into other silks, which differ at the molecular level. Silks are mainly produced by the larvae of insects undergoing complete metamorphosis, but also by some adult insects such as webspinners. Silk production is especially common in the Hymenoptera (bees, wasps, and ants), and is sometimes used in nest construction. Other types of arthropod produce silk, most notably various arachnids such as spiders (see spider silk).

History

Wild silk

A variety of wild silks, produced by caterpillars other than the mulberry silkworm have been known and used in China, South Asia, and Europe since ancient times. However, the scale of production was always far smaller than that of cultivated silks. They differ from the domesticated varieties in color and texture, and cocoons gathered in the wild usually have been damaged by the emerging moth before the cocoons are gathered, so the silk thread that makes up the cocoon has been torn into shorter lengths. Commercially reared silkworm pupae are killed by dipping them in boiling water before the adult moths emerge, or by piercing them with a needle, allowing the whole cocoon to be unraveled as one continuous thread. This permits a much stronger cloth to be woven from the silk. Wild silks also tend to be more difficult to dye than silk from the cultivated silkworm.

China

Silk fabric was first developed in ancient China,[1] with some of the earliest examples found as early as 3500 B.C.E.[2] Legend gives credit for developing silk to a Chinese empress, Lei Zu (Hsi-Ling-Shih, Lei-Tzu). Silks were originally reserved for the Kings of China for their own use and gifts to others, but spread gradually through Chinese culture and trade both geographically and socially, and then to many regions of Asia. Silk rapidly became a popular luxury fabric in the many areas accessible to Chinese merchants because of its texture and luster. Silk was in great demand, and became a staple of pre-industrial international trade. In July 2007, archeologists discovered intricately woven and dyed silk textiles in a tomb in Jiangxi province, dated to the Eastern Zhou Dynasty roughly 2,500 years ago.[3] Although historians have suspected a long history of a formative textile industry in ancient China, this find of silk textiles employing "complicated techniques" of weaving and dyeing provides direct and concrete evidence for silks dating before the Mawangdui-discovery and other silks dating to the Han Dynasty (202 B.C.E.-220 C.E.).[3]

The first evidence of the silk trade is the finding of silk in the hair of an Egyptian mummy of the 21st dynasty, c.1070 B.C.E.[4] Ultimately the silk trade reached as far as the Indian subcontinent, the Middle East, Europe, and North Africa. This trade was so extensive that the major set of trade routes between Europe and Asia has become known as the Silk Road. The highest development was in China.

The Emperors of China strove to keep knowledge of sericulture secret to maintain the Chinese monopoly. Nonetheless sericulture reached Korea around 200 B.C.E., about the first half of the 1st century AD had reached ancient Khotan,[5] and by AD 300 the practice had been established in India.[citation needed]

Thailand

Silk is produced, year round, in Thailand by two types of silkworms, the cultured Bombycidae and wild Saturniidae. Most production is after the rice harvest in the southern and northeast parts of the country. Women traditionally weave silk on hand looms, and pass the skill on to their daughters as weaving is considered to be a sign of maturity and eligibility for marriage. Thai silk textiles often use complicated patterns in various colours and styles. Most regions of Thailand have their own typical silks. A single thread filament is too thin to use on its own so women combine many threads to produce a thicker, usable fibre. They do this by hand-reeling the threads onto a wooden spindle to produce a uniform strand of raw silk. The process takes around 40 hours to produce a half kilogram of Thai silk.

Many local operations use a reeling machine for this task, but some silk threads are still hand-reeled. The difference is that hand-reeled threads produce three grades of silk: two fine grades that are ideal for lightweight fabrics, and a thick grade for heavier material.

The silk fabric is soaked in extremely cold water and bleached before dyeing to remove the natural yellow coloring of Thai silk yarn. To do this, skeins of silk thread are immersed in large tubs of hydrogen peroxide. Once washed and dried, the silk is woven on a traditional hand operated loom.[6]

India

Silk, known as "Paat" in Eastern India, Pattu in southern parts of India and Resham in Hindi/Urdu, has a long history in India. Recent archaeological discoveries in Harappa and Chanhu-daro suggest that sericulture, employing wild silk threads from native silkworm species, existed in South Asia during the time of the Indus Valley Civilization, roughly contemporaneous with the earliest known silk use in China.[7] Silk is widely produced today. India is the second largest producer of silk after China. A majority of the silk in India is produced in Karnataka State, particularly in Mysore and the North Bangalore regions of Muddenahalli, Kanivenarayanapura, and Doddaballapur.[8] India is also the largest consumer of silk in the world. The tradition of wearing silk sarees in marriages by the brides is followed in southern parts of India. Silk is worn by people as a symbol of royalty while attending functions and during festivals. Historically silk was used by the upper classes, while cotton was used by the poorer classes. Today silk is mainly produced in Bhoodhan Pochampally (also known as Silk City), Kanchipuram, Dharmavaram, Mysore, etc. in South India and Banaras in the North for manufacturing garments and sarees. "Murshidabad silk", famous from historical times, is mainly produced in Malda and Murshidabad district of West Bengal and woven with hand looms in Birbhum and Murshidabad district. Another place famous for production of silk is Bhagalpur. The silk from Pochampally is particularly well-known for its classic designs and enduring quality. The silk is traditionally hand-woven and hand-dyed and usually also has silver threads woven into the cloth. Most of this silk is used to make sarees. The sarees usually are very expensive and vibrant in color. Garments made from silk form an integral part of Indian weddings and other celebrations. In the northeastern state of Assam, three different types of silk are produced, collectively called Assam silk: Muga, Eri and Pat silk. Muga, the golden silk, and Eri are produced by silkworms that are native only to Assam. The heritage of silk rearing and weaving is very old and continues today especially with the production of Muga and Pat riha and mekhela chador, the three-piece silk sarees woven with traditional motifs. Mysore Silk Sarees, which are known for their soft texture, last many years if carefully maintained.

Ancient Mediterranean

In the Odyssey, 19.233, when Odysseus, while pretending to be someone else, is questioned by Penelope about her husband's clothing, he says that he wore a shirt "gleaming like the skin of a dried onion" (varies with translations, literal translation here)[9] which could refer to the lustrous quality of silk fabric. The Roman Empire knew of and traded in silk. During the reign of emperor Tiberius, sumptuary laws were passed that forbade men from wearing silk garments, but these proved ineffectual.[10] Despite the popularity of silk, the secret of silk-making only reached Europe around AD 550, via the Byzantine Empire. Legend has it that monks working for the emperor Justinian I smuggled silkworm eggs to Constantinople in hollow canes from China. All top-quality looms and weavers were located inside the Palace complex in Constantinople and the cloth produced was used in imperial robes or in diplomacy, as gifts to foreign dignitaries. The remainder was sold at very high prices.

Middle East

In Islamic teachings, Muslim men are forbidden to wear silk. Many religious jurists believe the reasoning behind the prohibition lies in avoiding clothing for men that can be considered feminine or extravagant.[11] There are disputes regarding the amount of silk a fabric can consist of (i.e., whether a small decorative silk piece on a cotton caftan is permissible or not) for it to be lawful for men to wear but the dominant opinion of most Muslim scholars is that the wearing of silk for men is forbidden.

Despite injunctions against silk for men, silk has retained its popularity in the Islamic world because of its permissibility for women. The Muslim Moors brought silk with them to Spain during their conquest of the Iberian Peninsula.

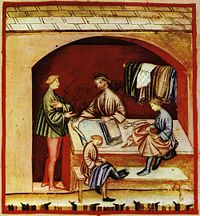

Medieval and modern Europe

Venetian merchants traded extensively in silk and encouraged silk growers to settle in Italy. By the 13th century, Italian silk was a significant source of trade. Since that period, the silk worked in the province of Como has been the most valuable silk in the world. The wealth of Florence was largely built on textiles, both wool and silk, and other cities like Lucca also grew rich on the trade. Italian silk was so popular in Europe that Francis I of France invited Armenian silk makers to France to create a French silk industry, especially in Lyon. Mass emigration (especially of Huguenots) during periods of religious dispute had seriously damaged French industry and introduced these various textile industries, including silk, to other countries. Silk was expensive in Medieval Europe and used only by the rich. Italian merchants like Giovanni Arnolfini became hugely wealthy trading it to the Courts of Northern Europe.

James I attempted to establish silk production in England, purchasing and planting 100,000 mulberry trees, some on land adjacent to Hampton Court Palace, but they were of a species unsuited to the silk worms, and the attempt failed. In 1717, John Lombe, visited Piedmont and returned to England with details of the Italian machines, and some Italian craftsmen. He was granted a fourteen year patent, and built Lombe's Mill in Derby. The King of Sardinia retaliated by prohibiting the export of raw silk. Nethertheless, in 1732 John Guardivaglio set up a silk throwing enterprise at Logwood mill in Stockport, and in 1744, Burton Mill was erected in Macclesfield and in 1753 Old Mill was built in Congleton.[12]. These three towns remained the centre of the English silk throwing industry until silk throwing was replaced by silk waste spinning. British enterprise also established silk filature in Cyprus in 1928. In England in the mid 20th Century, raw silk was produced at Lullingstone Castle in Kent. Silkworms were raised and reeled under the direction of Zoe Lady Hart Dyke. Production started elsewhere later.

In Italy, the Stazione Bacologica Sperimentale was founded in Padua in 1871 to research sericulture. In the late 19th century, China, Japan, and Italy were the major producers of silk.[13] The most important cities for silk production in Italy were Como and Meldola [14] (Forlì).

North America

James I of England introduced silk-growing to the American colonies around 1619, ostensibly to discourage tobacco planting. The Shakers in Kentucky adopted the practice as did a cottage industry in New England.[15] In the 19th century a new attempt at a silk industry began with European-born workers in Paterson, New Jersey, and the city became a US silk center, although Japanese imports were still more important.

World War II interrupted the silk trade from Japan. Silk prices increased dramatically, and US industry began to look for substitutes, which led to the use of synthetics such as nylon. Synthetic silks have also been made from lyocell, a type of cellulose fiber, and are often difficult to distinguish from real silk (see spider silk for more on synthetic silks).

Properties

Physical properties

Silk fibres from the Bombyx mori silkworm have a triangular cross section with rounded corners, 5-10 μm wide. The fibroin-heavy chain is composed mostly of beta-sheets, due to a 59-mer aminoacid repeat sequence with some variations.[16] The flat surfaces of the fibrils reflect light at many angles, giving silk a natural shine. The cross-section from other silkworms can vary in shape and diameter: crescent-like for Anaphe and elongated wedge for tussah. Silkworm fibres are naturally extruded from two silkworm glands as a pair of primary filaments (brin), which are stuck together, with sericin proteins that act like glue, to form a bave. Bave diameters for tussah silk can reach 65 μm. See cited reference for cross-sectional SEM photographs.[17]

Silk has a smooth, soft texture that is not slippery, unlike many synthetic fibers.

Silk is one of the strongest natural fibres but loses up to 20% of its strength when wet. It has a good moisture regain of 11%. Its elasticity is moderate to poor: if elongated even a small amount, it remains stretched. It can be weakened if exposed to too much sunlight. It may also be attacked by insects, especially if left dirty.

Silk is a poor conductor of electricity and thus susceptible to static cling.

Unwashed silk chiffon may shrink up to 8% due to a relaxation of the fibre macrostructure. So silk should either be pre-washed prior to garment construction, or dry cleaned. Dry cleaning may still shrink the chiffon up to 4%. Occasionally, this shrinkage can be reversed by a gentle steaming with a press cloth. There is almost no gradual shrinkage nor shrinkage due to molecular-level deformation.

Natural and synthetic silk is known to manifest piezoelectric properties in proteins, probably due to its molecular structure.[18]

Silkworm silk was used as the standard for the denier, a measurement of linear density in fibers. Silkworm silk therefore has a linear density of approximately 1 den, or 1.1 dtex.

| Comparison of silk fibers[19] | Linear Density(dtex) | Diameter (μm) | Coeff. Variation |

|---|---|---|---|

| Moth: Bombyx mori | 1.17 | 12.9 | 24.8% |

| Spider: Argiope aurentia | 0.14 | 3.57 | 14.8% |

Chemical properties

Silk emitted by the silkworm consists of two main proteins, sericin and fibroin, fibroin being the structural center of the silk, and serecin being the sticky material surrounding it. Fibroin is made up of the amino acids Gly-Ser-Gly-Ala-Gly-Ala and forms beta pleated sheets. Hydrogen bonds form between chains, and side chains form above and below the plane of the hydrogen bond network.

The high proportion (50%) of glycine, which is a small amino acid, allows tight packing and the fibers are strong and resistant to breaking. The tensile strength is due to the many interseeded hydrogen bonds, and when stretched the force is applied to these numerous bonds and they do not break.

Silk is resistant to most mineral acids, except for sulfuric acid, which dissolves it. It is yellowed by perspiration.

Uses

Silk's absorbency makes it comfortable to wear in warm weather and while active. Its low conductivity keeps warm air close to the skin during cold weather. It is often used for clothing such as shirts, ties, blouses, formal dresses, high fashion clothes, lingerie, pyjamas, robes, dress suits, sun dresses and kimonos.

Silk's attractive luster and drape makes it suitable for many furnishing applications. It is used for upholstery, wall coverings, window treatments (if blended with another fiber), rugs, bedding and wall hangings.[citation needed]

While on the decline now, due to artificial fibers, silk has had many industrial and commercial uses; parachutes, bicycle tires, comforter filling and artillery gunpowder bags.[citation needed]

A special manufacturing process removes the outer irritant sericin coating of the silk, which makes it suitable as non-absorbable surgical sutures. This process has also recently led to the introduction of specialist silk underclothing for children and adults with eczema where it can significantly reduce itch.[citation needed]

Production

The cultivation of silk is called sericulture. Over 30 countries produce silk, the major ones are China (54%) and India (14%).

To produce 1 kg of silk, 104 kg of mulberry leaves must be eaten by 3000 silkworms. It takes about 5000 silkworms to make a pure silk kimono.[20]

| Top Ten Cocoons (Reelable) Producers — 2005 | ||||

|---|---|---|---|---|

| Country | Production (Int $1000) | Footnote | Production (1000 kg) | Footnote |

| 978,013 | C | 290,003 | F | |

| 259,679 | C | 77,000 | F | |

| 57,332 | C | 17,000 | F | |

| 37,097 | C | 11,000 | F | |

| 20,235 | C | 6,000 | F | |

| 16,862 | C | 5,000 | F | |

| 10,117 | C | 3,000 | F | |

| 5,059 | C | 1,500 | F | |

| 3,372 | C | 1,000 | F | |

| 2,023 | C | 600 | F | |

| No symbol = official figure, F = FAO estimate, * = Unofficial figure, C = Calculated figure; Production in Int $1000 have been calculated based on 1999-2001 international prices | ||||

Cultivation

Silk moths lay eggs on specially prepared paper. The eggs hatch and the caterpillars (silkworms) are fed fresh mulberry leaves. After about 35 days and 4 moltings, the caterpillars are 10,000 times heavier than when hatched and are ready to begin spinning a cocoon. A straw frame is placed over the tray of caterpillars, and each caterpillar begins spinning a cocoon by moving its head in a "figure 8" pattern. Two glands produce liquid silk and force it through openings in the head called spinnerets. Liquid silk is coated in sericin, a water-soluble protective gum, and solidifies on contact with the air. Within 2–3 days, the caterpillar spins about 1 mile of filament and is completely encased in a cocoon. The silk farmers then kill most caterpillars by heat, leaving some to metamorphose into moths to breed the next generation of caterpillars.

Harvested cocoons are then soaked in boiling water to soften the sericin holding the silk fibers together in a cocoon shape. The fibers are then unwound to produce a continuous thread. Since a single thread is too fine and fragile for commercial use, anywhere from three to ten strands are spun together to form a single thread of silk.[21]

Animal rights

As the process of harvesting the silk from the cocoon kills the larvae, sericulture has been criticized in the early 21st century by animal rights activists, especially since artificial silks are available.[22] Mohandas Gandhi was also critical of silk production based on the Ahimsa philosophy "not to hurt any living thing." This led to Gandhi's promotion of cotton spinning machines, an example of which can be seen at the Gandhi Institute. He also promoted Ahimsa silk, wild silk made from the cocoons of wild and semi-wild silk moths.[23] Ahimsa silk is promoted in parts of Southern India for those who prefer not to wear silk produced by killing silkworms.[24][25]

See also

- Art silk

- Byzantine silk

- History of silk

- International Year of Natural Fibres 2009

- Mommes, the traditional density unit for silk.

- Rayon

- Silk in the Indian subcontinent

- Silk Road

- Silk waste

- Spider silk (with a discussion of synthetic silk)

- Tenun Pahang Diraja, famous woven silk fabric of Pahang, Malaysia.

- Thai silk

ReferencesISBN links support NWE through referral fees

- Notes

- ↑ Silk: History. Columbia Encyclopedia Sixth Edition.

- ↑ Textile Exhibition: Introduction. Asian art.

- ↑ 3.0 3.1 Chinese archaeologists make ground-breaking textile discovery in 2,500-year-old tomb. People's Daily Online.. Retrieved 2007-08-26.

- ↑ Lubec, G. and J. Holaubek, C. Feldl, B. Lubec, E. Strouhal (1993-03-04). Use of silk in ancient Egypt. Nature 362 (6415): 25. (also available here)

- ↑ Hill, John E. 2003. "Annotated Translation of the Chapter on the Western Regions according to the Hou Hanshu." 2nd Draft Edition. Appendix A. [1]

- ↑ About Thai silk from World of Thai Silk (commercial)

- ↑ (2009). New evidence for early silk in the Indus civilization. Archaeometry 50: 457.

- ↑ Silk city to come up near B’lore, Deccan Herald, 16 October 2009.

- ↑ Odyssey 19 233-234: τὸν δὲ χιτῶν' ἐνόησα περὶ χροῒ σιγαλόεντα, οἷόν τε κρομύοιο λοπὸν κάτα ἰσχαλέοιο· = "And I [= Odysseus

- ↑ Tacitus. Annals. ISBN 0521315433.

- ↑ Silk: Why It Is Haram for Men (2003-09-23). Archived from the original on 2007-03-02. Retrieved 2007-01-06.

- ↑ Callendine 1993

- ↑ Rayner 1903

- ↑ The Silkworm Museum, Meldola

- ↑ Mansfield Historical Society (2008). Retrieved 2009-03-30.

- ↑ "Handbook of Fiber Chemistry", Menachem Lewin, Editor, 3rd ed., 2006, CRC press, ISBN 0-8247-2565-4

- ↑ "Handbook of Fiber Chemistry", Menachem Lewin, Editor, 2nd ed.,1998, Marcel Dekker, pp. 438-441, ISBN 0-8247-9471-0

- ↑ Piezoelectricity in Natural and Synthetic Silks. Retrieved 28 April 2010.

- ↑ Frank K. Ko; Sueo Kawabata, Mari Inoue, Masako Niwa. Engineering Properties of Spider Silk. Retrieved 9 July 2010.

- ↑ Fritz, Anne and Cant, Jennifer (1986). Consumer Textiles. Oxford University Press Australia. Reprint 1987. ISBN 0 19 554647 4.

- ↑ Carrie Gleason: The Biography of Silk, page 12. Crabtree Publishing Company 2007.

- ↑ Down and Silk: Birds and Insects Exploited for Fabric. PETA. Retrieved 2007-01-06.

- ↑ "Mahatma Gandhi: 100 years", 1968, p. 349

- ↑ Silk Moths Fly Free Kusuma Rajaiah's Ahimsa project.

- ↑ Silk saree without killing a single silkworm Another article about Rajaiah and his methods.

- Bibliography

- Callandine, Anthony (1993). Lombe's Mill: An Exercise in reconstruction. Industrial Archaelogy Review XVI (1).

- Good, Irene. 1995. “On the question of silk in pre-Han Eurasia” Antiquity Vol. 69, Number 266, December 1995, pp. 959–968

- Hill, John E. 2004. The Peoples of the West from the Weilüe 魏略 by Yu Huan 魚豢: A Third Century Chinese Account Composed between 239 and 265 C.E. Draft annotated English translation. Appendix E.

- Kuhn, Dieter. 1995. “Silk Weaving in Ancient China: From Geometric Figures to Patterns of Pictorial Likeness.” Chinese Science 12 (1995): pp. 77–114.

- Liu, Xinru (1996). Silk and Religion: An Exploration of Material Life and the Thought of People, AD 600-1200. Oxford University Press.

- Liu, Xinru (2010). The Silk Road in World History. Oxford University Press. ISBN 978-0-19-516174-8; ISBN 978-0-19-533810-2 (pbk).

- Rayner, Hollins (1903). Silk throwing and waste silk spinning. Scott, Greenwood, Van Nostrand.

- Sung, Ying-Hsing. 1637. Chinese Technology in the Seventeenth Century - T'ien-kung K'ai-wu. Translated and annotated by E-tu Zen Sun and Shiou-chuan Sun. Pennsylvania State University Press, 1966. Reprint: Dover, 1997. Chap. 2. Clothing materials.

- Kadolph, Sara J. Textiles. 10th ed. Upper Saddle River: Pearson Prentice Hall, 2007. 76-81.

External links

- References to silk by Roman and Byzantine writers

- A series of maps depicting the global trade in silk

- History of traditional silk in martial arts uniforms

- Raising silkworms in classrooms for educational purposes (with photos)

- New thread in fabric of insect silks | physorg.com

| ||||||||||

| |||||||||||||||||||||||||||||||||||||

Template:Clothing Template:Use dmy dates

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.