Difference between revisions of "Soaps and Detergents" - New World Encyclopedia

| Line 8: | Line 8: | ||

There are, however, alternate ways in which the terms ''detergent'' and ''soap'' are used. For instance, the word ''detergent'' is often used when referring to synthetic cleaning agents that are not soaps (that is, not salts of fatty acids). Also, the word ''soap'' is applied to cleaning materials (such as "laundry soap") that do not contain salts of fatty acids. Most kinds of "soap" in use today are actually synthetic detergents, which are less expensive, more effective, and easier to manufacture. | There are, however, alternate ways in which the terms ''detergent'' and ''soap'' are used. For instance, the word ''detergent'' is often used when referring to synthetic cleaning agents that are not soaps (that is, not salts of fatty acids). Also, the word ''soap'' is applied to cleaning materials (such as "laundry soap") that do not contain salts of fatty acids. Most kinds of "soap" in use today are actually synthetic detergents, which are less expensive, more effective, and easier to manufacture. | ||

| + | Detergents are commonly used in products for personal hygiene, dishwashing, and laundry. They are also used as ingredients in antiseptic agents, dry-cleaning solutions, lubricating oils, and gasoline. | ||

| − | + | Although detergents are very useful, the excessive use of certain ingredients has led to adverse effects on the environment. For instance, [[phosphate]] additives used for [[water softener]]s led to an increase in phosphorus content in lakes and rivers, triggering [[algal bloom]]s that in turn consumed most of the [[oxygen]] in the waters, killing fish and plants. Efforts have been made to reduce such negative effects, but the results have been mixed. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== History == | == History == | ||

| Line 103: | Line 91: | ||

[[Image:Soap P1140887.jpg|thumb|200px|Handmade soaps sold at a shop in [[Hyères]], [[France]].]] | [[Image:Soap P1140887.jpg|thumb|200px|Handmade soaps sold at a shop in [[Hyères]], [[France]].]] | ||

| − | Some soap | + | Some individuals continue to make soap in the home. The traditional name "[[soaper]]," for a soap maker, is still used by those who make soap as a [[hobby]]. Those who make their own soaps are also known as soap crafters. |

| − | The | + | The most popular process for handmade soaps today is the cold process, where oils such as [[olive oil]] are reacted with [[lye]]. Some soap makers use the "melt and pour" process, where a pre-made soap base is melted and poured into individual molds. Some [[soaper]]s also practice other processes, such as the historical hot process, and make special soaps such as clear soap ([[glycerin soap]]). |

| − | |||

| − | |||

===Use of fats and oils === | ===Use of fats and oils === | ||

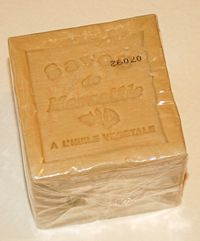

[[Image:Savon de Marseille.jpg|thumb|200px|Handicraft made [[Marseille soap]].]] | [[Image:Savon de Marseille.jpg|thumb|200px|Handicraft made [[Marseille soap]].]] | ||

| − | Soap is derived from either oils or fats. ''[[Sodium tallowate]]'', a common ingredient in many soaps, is | + | Soap is derived from either oils or fats. ''[[Sodium tallowate]]'', a common ingredient in many soaps, is derived from [[Kitchen rendering|rendered]] beef fat. Soap can also be made of vegetable oils, such as [[palm oil]], and the product is typically softer. |

| − | An array of quality oils and butters are used in the process | + | An array of quality oils and butters are used in the process, such as olive, coconut, palm, cocoa butter, [[hemp oil]] and shea butter. Each oil chosen by the soap maker has unique characteristics that provide different qualities to handmade soaps including mildness, lathering and hardness. For example, olive oil provides mildness in soap; coconut oil provides lots of lather while coconut and palm oils provides hardness. Most common, though, is a combination of coconut, palm, and olive oils. |

| + | |||

| + | If soap is made from pure [[olive oil]] it may be called [[Castile soap]] or [[Marseille soap]]. The term "Castile soap" is also sometimes applied to soaps with a mix of oils, but a high percentage of olive oil. | ||

===Reactions with alkali=== | ===Reactions with alkali=== | ||

| − | When fat is reacted with lye ([[sodium hydroxide]]), the product is a hard soap. When fat is reacted with [[potassium hydroxide]], the product is a soap that is either soft or liquid. Either reaction is known as ''[[saponification]]''. The fat is [[Hydrolysis|hydrolyzed]] by the alkali, yielding [[glycerol]] and crude soap. Historically, the alkali used was potassium hydroxide, made from the deliberate burning of vegetation such as [[bracken]], or from wood ashes. | + | When fat (or oil) is reacted with lye ([[sodium hydroxide]]), the product is a hard soap. When fat is reacted with [[potassium hydroxide]], the product is a soap that is either soft or liquid. Either reaction is known as ''[[saponification]]''. The fat is [[Hydrolysis|hydrolyzed]] by the alkali, yielding [[glycerol]] and crude soap. Historically, the alkali used was potassium hydroxide, made from the deliberate burning of vegetation such as [[bracken]], or from wood ashes. |

=== Cold and hot processes === | === Cold and hot processes === | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

;Hot process | ;Hot process | ||

| − | In the hot-process method, lye and [[fatty acid|fat]] are boiled together at 80 – 100 °C until saponification occurs, | + | In the hot-process method, lye and [[fatty acid|fat]] are boiled together at 80–100 °C until saponification occurs. After saponification, the soap is sometimes [[precipitation (chemistry)|precipitated]] from the solution by adding salt, and the excess liquid drained off. The hot, soft soap is then spooned into a mold. |

| − | + | The hot-process method was used when the purity of lye was unreliable, and when naturally produced lye, such as [[potash]], was used. The main benefit of hot processing is that the exact concentration of the lye solution does not need to be known to perform the process with adequate success. | |

| − | |||

| − | The hot-process method was used when the purity of lye was unreliable, and | ||

| + | Unlike cold-processed soap, hot-processed soap can be used right away because lye and fat saponify more quickly at the higher temperatures used in hot-process soap making. | ||

;Cold process | ;Cold process | ||

| Line 140: | Line 122: | ||

In the cold-process method, fats such as [[olive oil]] are reacted with [[Sodium Hydroxide|lye]], at a temperature that is sufficiently above room temperature to ensure the [[melting|liquefaction]] of the fat being used. It requires that the lye and fat be kept warm after mixing to ensure that the soap is completely saponified. | In the cold-process method, fats such as [[olive oil]] are reacted with [[Sodium Hydroxide|lye]], at a temperature that is sufficiently above room temperature to ensure the [[melting|liquefaction]] of the fat being used. It requires that the lye and fat be kept warm after mixing to ensure that the soap is completely saponified. | ||

| − | The cold process requires exact measurement of lye to fat using saponification charts, to ensure that the finished product is mild and skin friendly. Excess unreacted lye in the soap will result in a very high pH and can burn or irritate skin. Not enough lye, and the soap is greasy and oily. Most soap makers formulate their recipes with a 4-10% discount of lye so that all of the lye is reacted and that excess fat is left for skin conditioning benefits. | + | The cold process requires exact measurement of lye to fat using saponification charts, to ensure that the finished product is mild and skin friendly. Excess unreacted lye in the soap will result in a very high pH and can burn or irritate skin. Not enough lye, and the soap is greasy and oily. Most soap makers formulate their recipes with a 4-10% discount of lye so that all of the lye is reacted and that excess fat is left for skin conditioning benefits. (Saponification charts can also be used in hot-process soap making, but are not as necessary as for the cold-process method.) |

| − | + | The lye is dissolved in water. Then oils are heated, or melted if they are solid at room temperature. Once both substances have cooled to approximately 100-110 degrees Fahrenheit, and are no more than 10 degrees Fahrenheit apart in temperature, they may be combined. This lye-fat mixture is stirred until it reaches a stage called "trace"—the point at which the saponification process is sufficiently advanced that the soap has begun to thicken. (Modern-day amateur soap makers often use a stick blender to speed this process.). There are varying levels of trace: light, medium, and heavy. | |

| − | + | [[Essential oil]]s, [[fragrance oil]]s, botanicals, herbs, oatmeal or other additives are added at light trace, just as the mixture starts to thicken. The batch is then poured into molds, kept warm with towels or blankets, and left to continue saponification for 18 to 48 hours. | |

| − | + | After the insulation period, the soap is firm enough to be removed from the mold and cut into bars. At this time, it is safe to use the soap since saponification is complete. However, cold-process soaps are typically cured and hardened on a drying rack for 2-6 weeks (depending on initial water content) before use. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | After the insulation period the soap is firm enough to be removed from the mold and cut into bars. At this time, it is safe to use the soap since saponification is complete. However, cold-process soaps are typically cured and hardened on a drying rack for 2-6 weeks (depending on initial water content) before use | ||

===Purification and finishing=== | ===Purification and finishing=== | ||

| Line 166: | Line 142: | ||

[[Sand]] or [[pumice]] may be added to produce a [[wiktionary:scouring|scouring]] soap. This process is most common in creating soaps used for human hygiene. The scouring agents serve to remove dead skin cells from the surface being cleaned. This process is called [[exfoliation (cosmetology)|exfoliation]]. Many newer materials are used for exfoliating soaps which are effective but do not have the sharp edges and poor size distribution of pumice. | [[Sand]] or [[pumice]] may be added to produce a [[wiktionary:scouring|scouring]] soap. This process is most common in creating soaps used for human hygiene. The scouring agents serve to remove dead skin cells from the surface being cleaned. This process is called [[exfoliation (cosmetology)|exfoliation]]. Many newer materials are used for exfoliating soaps which are effective but do not have the sharp edges and poor size distribution of pumice. | ||

| − | === | + | ==Disadvantages== |

| − | |||

| − | + | Today, fat-based soaps have mostly been superseded by modern [[detergent]]s. Washing agents do not contain soap for cleaning fabric, but for reducing foam. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | Today, fat-based soaps have mostly been superseded by modern [[detergent]]s. | ||

The disadvantages of commercial soaps are: | The disadvantages of commercial soaps are: | ||

*Due to the fact that most commercial soaps eliminate the glycerine from soaps to use in other industires, this deprives the [[skin]] of the natural, moisturising glycerine and generally leaves the skin feeling dry. | *Due to the fact that most commercial soaps eliminate the glycerine from soaps to use in other industires, this deprives the [[skin]] of the natural, moisturising glycerine and generally leaves the skin feeling dry. | ||

*Some antibacterial soaps have chemicals killing bacteria that coexist on the skin's surface and are essential to skin health. More alarmingly, the rise of antibacterial soaps contributes to [[antibiotic resistant]] bacteria. {{fact}} | *Some antibacterial soaps have chemicals killing bacteria that coexist on the skin's surface and are essential to skin health. More alarmingly, the rise of antibacterial soaps contributes to [[antibiotic resistant]] bacteria. {{fact}} | ||

| − | *Soap-based products often contain the additive [[sodium laureth sulfate]], which research has found to be harsh on skin. This product is also present in many non-soap cleaners for personal hygiene (shampoos, bathfoams, toothpaste | + | *Soap-based products often contain the additive [[sodium laureth sulfate]], which research has found to be harsh on skin. This product is also present in many non-soap cleaners for personal hygiene (such as shampoos, bathfoams, toothpaste). |

*Soap can react mildly [[Base (chemistry)|basically]] with fabrics resulting in damage over the long term. This is usually due to excess [[sodium]] [[hydroxide]] ([[sodium hydroxide|NaOH]], an [[alkali]]/base) left from manufacture, but can also be caused by the very slight presence of NaOH from the [[equilibrium reaction]]:<br/>R-COO-Na + H<sub>2</sub>O ↔ R-COO<sup>-</sup> + Na<sup>+</sup> + H<sub>2</sub>O ↔ R-COOH + NaOH <br/>However, this equilibrium strongly favors the left-hand side so the fraction of NaOH formed is minuscule | *Soap can react mildly [[Base (chemistry)|basically]] with fabrics resulting in damage over the long term. This is usually due to excess [[sodium]] [[hydroxide]] ([[sodium hydroxide|NaOH]], an [[alkali]]/base) left from manufacture, but can also be caused by the very slight presence of NaOH from the [[equilibrium reaction]]:<br/>R-COO-Na + H<sub>2</sub>O ↔ R-COO<sup>-</sup> + Na<sup>+</sup> + H<sub>2</sub>O ↔ R-COOH + NaOH <br/>However, this equilibrium strongly favors the left-hand side so the fraction of NaOH formed is minuscule | ||

*Soap reacts with [[Lime (mineral)|lime]] to form an insoluble deposit (soap scum) in "[[Water Hardness|hard water]]":<br/>2Na<sup>+</sup>(R-COO)<sup>-</sup><sub>(aq)</sub> + Ca<sup>2+</sup>(HCO<sub>3</sub><sup>-</sup>)<sub>2</sub><sub>(aq)</sub> → 2Na<sup>+</sup>(HCO<sub>3</sub>)<sup>-</sup><sub>(aq)</sub> + Ca(R-COO)<sub>2</sub><sub>(s)</sub> - where R stands for an [[alkyl]] group (precipitate) | *Soap reacts with [[Lime (mineral)|lime]] to form an insoluble deposit (soap scum) in "[[Water Hardness|hard water]]":<br/>2Na<sup>+</sup>(R-COO)<sup>-</sup><sub>(aq)</sub> + Ca<sup>2+</sup>(HCO<sub>3</sub><sup>-</sup>)<sub>2</sub><sub>(aq)</sub> → 2Na<sup>+</sup>(HCO<sub>3</sub>)<sup>-</sup><sub>(aq)</sub> + Ca(R-COO)<sub>2</sub><sub>(s)</sub> - where R stands for an [[alkyl]] group (precipitate) | ||

| − | |||

*Poorly finished soaps contain [[alkali]] ([[sodium hydroxide|NaOH]]) and react mildly [[Base (chemistry)|basically]] with skin and fabric; commercial products are finished to neutrality or to a weak [[acid]] content to prevent this and be more compatible with the [[skin|skin's]] slightly [[acidic]] [[pH]]. | *Poorly finished soaps contain [[alkali]] ([[sodium hydroxide|NaOH]]) and react mildly [[Base (chemistry)|basically]] with skin and fabric; commercial products are finished to neutrality or to a weak [[acid]] content to prevent this and be more compatible with the [[skin|skin's]] slightly [[acidic]] [[pH]]. | ||

| − | *Commercial products use [[chelation|chelating]] molecules ([[sequestrant]]s), often [[EDTA]] derivatives to bind with any free {{Calcium}} or {{Magnesium}} ions and prevent [[soap scum]]. These also help reduce fragrance loss, | + | *Commercial products use [[chelation|chelating]] molecules ([[sequestrant]]s), often [[EDTA]] derivatives to bind with any free {{Calcium}} or {{Magnesium}} ions and prevent [[soap scum]]. These also help reduce fragrance loss, discoloration. and [[Rancidification|rancidity]]. |

*Castile soap has a very high alkalinity level, measured at about 9. pH of skin and hair has a slightly acidic pH level known to be about 5 to 6. Due to the high pH level, liquid castile soap is usually not recommended by soapmakers who market this high pH soap for washing hair because it is not pH-balanced and it may cause hair to become dry. | *Castile soap has a very high alkalinity level, measured at about 9. pH of skin and hair has a slightly acidic pH level known to be about 5 to 6. Due to the high pH level, liquid castile soap is usually not recommended by soapmakers who market this high pH soap for washing hair because it is not pH-balanced and it may cause hair to become dry. | ||

== Environmental concerns == | == Environmental concerns == | ||

| − | In the 1960s, detergent manufacturers waged an advertising battle over who had the longest lasting suds, and detergent compounds quickly appeared in the waterways. Suds began to appear in streams, rivers, lakes | + | In the 1960s, detergent manufacturers waged an advertising battle over who had the longest lasting suds, and detergent compounds quickly appeared in the waterways. Suds began to appear in streams, rivers, and lakes. At the foot of the [[Niagara Falls]], piles of discolored detergent foam rose eight feet high. |

Detergents also contain phosphate additives to soften the water and thereby improve the effectiveness of the detergent molecules. It was noted that between 1940 and 1970 the amount of [[phosphates]] in city wastewater increased from 20,000 to 150,000 tons per year. | Detergents also contain phosphate additives to soften the water and thereby improve the effectiveness of the detergent molecules. It was noted that between 1940 and 1970 the amount of [[phosphates]] in city wastewater increased from 20,000 to 150,000 tons per year. | ||

| Line 198: | Line 165: | ||

==Uses== | ==Uses== | ||

| − | [[Image:Washingpowder.jpg|thumb|[[Laundry detergent]]s are | + | [[Image:Washingpowder.jpg|thumb|[[Laundry detergent]]s are among the many possible uses of detergents.]] |

| − | Detergents are mainly used for | + | Detergents are mainly used in products for personal hygiene, dishwashing, and laundry. In addition, detergents are often added to a variety of products, to prevent the buildup of undesirable deposits. Some products that may contain detergents include: |

* toothpastes | * toothpastes | ||

* antiseptic agents | * antiseptic agents | ||

| Line 211: | Line 178: | ||

== Caution == | == Caution == | ||

| − | Allowing | + | Allowing a detergent to sit on any surface (such as skin or clothes) over time can cause an imbalance in [[pH]] and moisture content on the surface, damaging the fabric and injuring the skin. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==See also== | ==See also== | ||

Revision as of 21:35, 15 November 2007

- For other uses, see Soaps and Detergents (disambiguation).

A detergent is a chemical compound or mixture of compounds used as a cleaning agent. A soap is a cleaning agent that is composed of one or more salts of fatty acids. In this sense, detergent is an umbrella term that includes soaps and other cleaning agents that differ in chemical composition. Even plain water, when used for cleaning, may be called a detergent.

There are, however, alternate ways in which the terms detergent and soap are used. For instance, the word detergent is often used when referring to synthetic cleaning agents that are not soaps (that is, not salts of fatty acids). Also, the word soap is applied to cleaning materials (such as "laundry soap") that do not contain salts of fatty acids. Most kinds of "soap" in use today are actually synthetic detergents, which are less expensive, more effective, and easier to manufacture.

Detergents are commonly used in products for personal hygiene, dishwashing, and laundry. They are also used as ingredients in antiseptic agents, dry-cleaning solutions, lubricating oils, and gasoline.

Although detergents are very useful, the excessive use of certain ingredients has led to adverse effects on the environment. For instance, phosphate additives used for water softeners led to an increase in phosphorus content in lakes and rivers, triggering algal blooms that in turn consumed most of the oxygen in the waters, killing fish and plants. Efforts have been made to reduce such negative effects, but the results have been mixed.

History

Early History

The earliest known use of a natural, soap-like material was the powder of nuts from the Reeta (Sapindus) tree, a powder used by Indians since antiquity. In accordance with Ayurvedic teachings, Hindus in India were obliged to bathe at least once a day, every morning.

The Babylonians used clay cylinders containing a soap-like substance, dating from 2800 B.C.E. A formula for soap—consisting of water, alkali, and cassia oil—was written on a Babylonian clay tablet around 2200 B.C.E.

The Ebers papyrus (Egypt, 1550 B.C.E.) indicates that ancient Egyptians bathed regularly and combined animal and vegetable oils with alkaline salts to create a soap-like substance. Egyptian documents mention that a soap-like substance was used in the preparation of wool for weaving.

Roman History

It has been reported that a factory producing soap-like substances was found in the ruins of Pompeii (CE 79). However, this report appears to be a misinterpretation of the survival of some soapy mineral substance, probably soapstone, at the Fullonica where it was used for dressing recently cleansed textiles. The ancient Romans were generally ignorant of soap's detergent properties and made use of the strigil to scrape dirt and sweat from the body.

The word "soap" (Latin sapo) appears first in a European language in Pliny the Elder's Historia Naturalis, which discusses the manufacture of soap from tallow and ashes, but the only use he mentions for it is as a pomade for hair. He mentions rather disapprovingly that among the Gauls and Germans, men are likelier to use it than women.[1]

According to one legend, "soap" takes its name from a "Mount Sapo" where ancient Romans sacrificed animals. Rain would send a mix of animal tallow and wood ash down the mountain and into the clay soil on the banks of the Tiber. Eventually, women noticed that it was easier to clean clothes with this "soap." The location of Mount Sapo is unknown, as is the source of the "ancient Roman legend" to which this tale is typically credited.[2]

In fact, the Latin word sapo simply means "soap." Borrowed from a Celtic or Germanic language, the term is cognate with the Latin term sebum (meaning "tallow"), which appears in Pliny the Elder's account. Roman animal sacrifices usually burned only the bones and inedible entrails of the sacrificed animals; edible meat and fat from the sacrifices were taken by humans. Under such circumstances, animal sacrifices would not have included enough fat to make much soap. The legend about Mount Sapo is probably apocryphal.

Muslim History

True soaps made from vegetable oils (such as olive oil), aromatic oils (such as thyme oil), and lye (al-Soda al-Kawia, or sodium hydroxide), were first produced by Muslim chemists in the medieval Islamic world.[3] From the beginning of the seventh century, soap was produced in Nablus (West Bank, Palestine), Kufa (Iraq) and Basra (Iraq). Soaps as we know them today are descendants of historical Arabian soaps.

Arabian soaps were perfumed and colored; some were liquid, others were hard. The Arabs also had special soap for shaving. It was commercially sold for 3 Dirhams (0.3 Dinars) a piece in CE 981. The Persian chemist Al-Razi wrote a manuscript on recipes for true soap. A recently discovered manuscript from the thirteenth century details more recipes for soap making. One recipe recommends taking some sesame oil, a sprinkle of potash, alkali and some lime, mixing them together, and boiling. When cooked, they are poured into molds and left to set, leaving hard soap.

Historically, soap was made by mixing animal fats with lye. Because of the caustic nature of lye, this was a dangerous procedure, which could result in serious chemical burns or even blindness. Before the commercial production of lye became commonplace, it was produced at home for soap making from the ashes of a hardwood fire.

Modern History

Castile soap, made from olive oil, was produced in Europe as early as the sixteenth century.

In modern times, the use of soap has become universal in industrialized nations due to a better understanding of the role of hygiene in reducing the population size of pathogenic microorganisms. Manufactured bar soaps first became available in the late nineteenth century, and advertising campaigns in Europe and the United States helped to increase popular awareness of the relationship between cleanliness and health. By the 1950s, soap had gained public acceptance as an instrument of personal hygiene.

Commercial soap production

Until the Industrial Revolution, soap-making was done on a small scale and the product was rough. In 1789, Andrew Pears started making a high-quality, transparent soap in London. He and his grandson, Francis Pears, opened a factory in Isleworth in 1862. William Gossage produced low-priced, good quality soap from the 1850s. Robert Spear Hudson began manufacturing a soap powder in 1837, initially by grinding the soap with a mortar and pestle. William Hesketh Lever and his brother James bought a small soap works in Warrington in 1885 and founded what became one of the largest soap businesses, now called Unilever. These soap businesses were among the first to employ large-scale advertising campaigns to sell the output of their factories.

Forms of soap

Soap usually comes in a solid, molded form, called a bar, based on its typical shape. The use of thick liquid soap has also become widespread, especially from soap dispensers in public washrooms. When applied to a soiled surface, soapy water effectively holds particles in suspension, which can then be rinsed off with clean water.

Components of detergents and their functions

As noted above, soaps are salts of fatty acids. A molecule of soap may be represented as follows:

- (fatty end) :CH3-(CH2)n - COO−Na+: (water soluble end)

Thus, each molecule of soap has (a) an ionic end, which is hydrophilic (water-attracting) and soluble in water; and (b) a nonpolar hydrocarbon chain that is hydrophobic (water-repelling) that can attach to nonpolar materials such as grease and oil. These molecules form bridges between water and oil, breaking up the oil and forming an emulsion consisting of oil droplets suspended in water. Substances made up of such molecules are called surfactants. They reduce the surface tension of water, and they reduce interfacial tension between oil and water by adsorbing at the liquid-liquid interface.

Surfactants are key components of detergents in general. Because of their presence in detergents, oil and associated dirt particles become solubilized and can be rinsed away with clean water.

Many types of organic compounds can function as surfactants. They (and the detergents that contain them) are often classified into four groups: anionic, cationic, zwitterionic (with plus and minus charges), and non-ionic. In the case of non-ionic surfactants, the hydrophilic nature of one end is conferred by the presence of special functional groups such as hydroxyl groups. Most brands of laundry detergent have anionic or nonionic surfactants or a mixture of the two, although cationic surfactants have also been used. The use of cationic and anionic surfactants together is incompatible in the same detergent. The usual content of surfactants in a typical detergent is about 8-18 percent.

In addition to surfactants, detergents various other components that serve different functions.[4] A given detergent may contain several of the following components:

- Abrasives that scour the surfaces.

- Substances that modify or control pH, or affect the performance or stability of other ingredients. For example, acids may be used for descaling, or caustics to destroy dirt.

- Water softeners counteract the effect of "hardness" ions (particularly calcium and magnesium ions). Some form of sodium phosphate (such as trisodium orthophosphate, monosodium orthophosphate, or a tripolyphosphate) can be used here. In some locations, phosphate is no longer used due to environmental concerns, as phosphates in surface waters stimulate algal bloom. As alternatives, other chelating agents or ion exchange materials are used.

- Oxidizing agents (oxidizers) that bleach surfaces and destroy dirt. In North America, sodium hypochlorite based bleach additives are more common. These work at lower temperatures and do not need activation. In Europe, peroxide-based bleaches are prevalent.

- Fillers, forming a bulk component in many laundry detergents, modify the physical properties of the material. In solid detergents, sodium sulfate or borax can be used to make the powder free-flowing. In liquid detergents, alcohols are added to increase the solubility of the compounds and to lower the mixture's freezing point.

- Non-surfactant materials that keep dirt in suspension.

- Enzymes that digest proteins, fats, or carbohydrates. They help remove biological stains (such as stains from grass or blood). Enzymes produced by the bacteria Bacillus subtilis and Bacillus licheniformis are often used.

- Ingredients that modify the foaming properties of the cleaning surfactants, to either stabilize or counteract foam.

- Additional ingredients include optical brighteners, fabric softeners, colors, and perfumes.

The material to be cleaned dictates the composition of the detergent that should be used and the apparatus to be used. For instance, the following are examples of different glass-cleaning agents that are appropriate for different contexts:

- A chromic acid solution is used to get glass very clean for precision-demanding purposes, such as analytical chemistry

- A high-foaming mixture of surfactants with low skin irritation is needed for hand washing of drinking glasses in a sink or dishpan.

- Any of various non-foaming compositions are used for glasses in a dishwashing machine.

- An ammonia-containing solution is useful for cleaning windows, with no need for rinsing.

- Windshield washer fluid is useful especially when a vehicle is in motion.

Soap making

Some individuals continue to make soap in the home. The traditional name "soaper," for a soap maker, is still used by those who make soap as a hobby. Those who make their own soaps are also known as soap crafters.

The most popular process for handmade soaps today is the cold process, where oils such as olive oil are reacted with lye. Some soap makers use the "melt and pour" process, where a pre-made soap base is melted and poured into individual molds. Some soapers also practice other processes, such as the historical hot process, and make special soaps such as clear soap (glycerin soap).

Use of fats and oils

Soap is derived from either oils or fats. Sodium tallowate, a common ingredient in many soaps, is derived from rendered beef fat. Soap can also be made of vegetable oils, such as palm oil, and the product is typically softer.

An array of quality oils and butters are used in the process, such as olive, coconut, palm, cocoa butter, hemp oil and shea butter. Each oil chosen by the soap maker has unique characteristics that provide different qualities to handmade soaps including mildness, lathering and hardness. For example, olive oil provides mildness in soap; coconut oil provides lots of lather while coconut and palm oils provides hardness. Most common, though, is a combination of coconut, palm, and olive oils.

If soap is made from pure olive oil it may be called Castile soap or Marseille soap. The term "Castile soap" is also sometimes applied to soaps with a mix of oils, but a high percentage of olive oil.

Reactions with alkali

When fat (or oil) is reacted with lye (sodium hydroxide), the product is a hard soap. When fat is reacted with potassium hydroxide, the product is a soap that is either soft or liquid. Either reaction is known as saponification. The fat is hydrolyzed by the alkali, yielding glycerol and crude soap. Historically, the alkali used was potassium hydroxide, made from the deliberate burning of vegetation such as bracken, or from wood ashes.

Cold and hot processes

- Hot process

In the hot-process method, lye and fat are boiled together at 80–100 °C until saponification occurs. After saponification, the soap is sometimes precipitated from the solution by adding salt, and the excess liquid drained off. The hot, soft soap is then spooned into a mold.

The hot-process method was used when the purity of lye was unreliable, and when naturally produced lye, such as potash, was used. The main benefit of hot processing is that the exact concentration of the lye solution does not need to be known to perform the process with adequate success.

Unlike cold-processed soap, hot-processed soap can be used right away because lye and fat saponify more quickly at the higher temperatures used in hot-process soap making.

- Cold process

In the cold-process method, fats such as olive oil are reacted with lye, at a temperature that is sufficiently above room temperature to ensure the liquefaction of the fat being used. It requires that the lye and fat be kept warm after mixing to ensure that the soap is completely saponified.

The cold process requires exact measurement of lye to fat using saponification charts, to ensure that the finished product is mild and skin friendly. Excess unreacted lye in the soap will result in a very high pH and can burn or irritate skin. Not enough lye, and the soap is greasy and oily. Most soap makers formulate their recipes with a 4-10% discount of lye so that all of the lye is reacted and that excess fat is left for skin conditioning benefits. (Saponification charts can also be used in hot-process soap making, but are not as necessary as for the cold-process method.)

The lye is dissolved in water. Then oils are heated, or melted if they are solid at room temperature. Once both substances have cooled to approximately 100-110 degrees Fahrenheit, and are no more than 10 degrees Fahrenheit apart in temperature, they may be combined. This lye-fat mixture is stirred until it reaches a stage called "trace"—the point at which the saponification process is sufficiently advanced that the soap has begun to thicken. (Modern-day amateur soap makers often use a stick blender to speed this process.). There are varying levels of trace: light, medium, and heavy.

Essential oils, fragrance oils, botanicals, herbs, oatmeal or other additives are added at light trace, just as the mixture starts to thicken. The batch is then poured into molds, kept warm with towels or blankets, and left to continue saponification for 18 to 48 hours.

After the insulation period, the soap is firm enough to be removed from the mold and cut into bars. At this time, it is safe to use the soap since saponification is complete. However, cold-process soaps are typically cured and hardened on a drying rack for 2-6 weeks (depending on initial water content) before use.

Purification and finishing

The common process of purifying soap involves removal of sodium chloride, sodium hydroxide, and glycerol. These components are removed by boiling the crude soap curds in water and re-precipitating the soap with salt.

Most of the water is then removed from the soap. This was traditionally done on a chill roll which produced the soap flakes commonly used in the 1940s and 1950s. This process was superseded by spray dryers and then by vacuum dryers.

The dry soap (approximately 6-12% moisture) is then compacted into small pellets. These pellets are now ready for soap finishing, the process of converting raw soap pellets into a salable product, usually bars.

Soap pellets are combined with fragrances and other materials and blended to homogeneity in an amalgamator (mixer). The mass is then discharged from the mixer into a refiner which, by means of an auger, forces the soap through a fine wire screen. From the refiner the soap passes over a roller mill (French milling or hard milling) in a manner similar to calendering paper or plastic or to making chocolate liquor. The soap is then passed through one or more additional refiners to further plasticize the soap mass. Immediately before extrusion it passes through a vacuum chamber to remove any entrapped air. It is then extruded into a long log or blank, cut to convenient lengths, passed through a metal detector and then stamped into shape in refrigerated tools. The pressed bars are packaged in many ways.

Sand or pumice may be added to produce a scouring soap. This process is most common in creating soaps used for human hygiene. The scouring agents serve to remove dead skin cells from the surface being cleaned. This process is called exfoliation. Many newer materials are used for exfoliating soaps which are effective but do not have the sharp edges and poor size distribution of pumice.

Disadvantages

Today, fat-based soaps have mostly been superseded by modern detergents. Washing agents do not contain soap for cleaning fabric, but for reducing foam.

The disadvantages of commercial soaps are:

- Due to the fact that most commercial soaps eliminate the glycerine from soaps to use in other industires, this deprives the skin of the natural, moisturising glycerine and generally leaves the skin feeling dry.

- Some antibacterial soaps have chemicals killing bacteria that coexist on the skin's surface and are essential to skin health. More alarmingly, the rise of antibacterial soaps contributes to antibiotic resistant bacteria. [citation needed]

- Soap-based products often contain the additive sodium laureth sulfate, which research has found to be harsh on skin. This product is also present in many non-soap cleaners for personal hygiene (such as shampoos, bathfoams, toothpaste).

- Soap can react mildly basically with fabrics resulting in damage over the long term. This is usually due to excess sodium hydroxide (NaOH, an alkali/base) left from manufacture, but can also be caused by the very slight presence of NaOH from the equilibrium reaction:

R-COO-Na + H2O ↔ R-COO- + Na+ + H2O ↔ R-COOH + NaOH

However, this equilibrium strongly favors the left-hand side so the fraction of NaOH formed is minuscule - Soap reacts with lime to form an insoluble deposit (soap scum) in "hard water":

2Na+(R-COO)-(aq) + Ca2+(HCO3-)2(aq) → 2Na+(HCO3)-(aq) + Ca(R-COO)2(s) - where R stands for an alkyl group (precipitate) - Poorly finished soaps contain alkali (NaOH) and react mildly basically with skin and fabric; commercial products are finished to neutrality or to a weak acid content to prevent this and be more compatible with the skin's slightly acidic pH.

- Commercial products use chelating molecules (sequestrants), often EDTA derivatives to bind with any free Ca or Mg ions and prevent soap scum. These also help reduce fragrance loss, discoloration. and rancidity.

- Castile soap has a very high alkalinity level, measured at about 9. pH of skin and hair has a slightly acidic pH level known to be about 5 to 6. Due to the high pH level, liquid castile soap is usually not recommended by soapmakers who market this high pH soap for washing hair because it is not pH-balanced and it may cause hair to become dry.

Environmental concerns

In the 1960s, detergent manufacturers waged an advertising battle over who had the longest lasting suds, and detergent compounds quickly appeared in the waterways. Suds began to appear in streams, rivers, and lakes. At the foot of the Niagara Falls, piles of discolored detergent foam rose eight feet high.

Detergents also contain phosphate additives to soften the water and thereby improve the effectiveness of the detergent molecules. It was noted that between 1940 and 1970 the amount of phosphates in city wastewater increased from 20,000 to 150,000 tons per year.

With the increase in phosphates, algal blooms grew splendidly on the excess phosphorus and consumed the majority of all oxygen in the waters, killing fish and plants.

Uses

Detergents are mainly used in products for personal hygiene, dishwashing, and laundry. In addition, detergents are often added to a variety of products, to prevent the buildup of undesirable deposits. Some products that may contain detergents include:

- toothpastes

- antiseptic agents

- dry-cleaning solutions

- gasoline

- lubricating oils

A nature-friendly way of interrupting an ant trail is to pour soapy water on the trail. The soapy water destroys the scent the ants were following to get to food.

Caution

Allowing a detergent to sit on any surface (such as skin or clothes) over time can cause an imbalance in pH and moisture content on the surface, damaging the fabric and injuring the skin.

See also

- Fatty acid

- Phosphate

- Potassium hydroxide

- Sodium hydroxide

Notes

- ↑ Pliny the Elder, Natural History, XXVIII.191. Retrieved November 14, 2007.

- ↑ [1]

- ↑ Ahmad Y Hassan, Technology Transfer in the Chemical Industries.

- ↑ Detergents. Retrieved November 14, 2007.

ReferencesISBN links support NWE through referral fees

- Garzena, Patrizia - Tadiello, Marina (2004). Soap Naturally - Ingredients, methods and recipes for natural handmade soap. Programmer Publishing. ISBN 978-0975676400.

- Maine, Sandy (1995). The Soap Book: Simple Herbal Recipes. Interweave Press. ISBN 1-883010-14-4.

- Tarekh Al-Masoudi\the first book. [The Masoudi History-printed in 1989 Beirut-Lebanon]

External links

History

- Soap history by The Soap and Detergent Association

- The Discovery and Prehistory of Soap by R W Hedge at Butser Ancient Farm

- The History of Soap by C'etrange

- History of soap by the Pharmaceutical Journal

- Colonial Soap Making. Its History and Techniques. (The Soap Factory)

- Soap Naturally by Patrizia Garzena, contains a history of soap; rebuts the "Mount Sapo" legend.

Soap making

- About Candle and Soap Making - Soap making projects, instructions, recipes, suppliers and more from About.com

- Glossary for the Modern Soap Maker. Soap making terminology defined.

- Create The Dream Magazine - Magazine for Artisans of Soap, Candle, and Herbal Products.

- Creative Artisans Network.

- The Soap Making Home Page

- Handcrafted Soap Maker's Guild

- Soap Making Instructions & Recipes

- Instructions for Making Crock Pot Handmade Soap

Other

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.