Composite material

Composite materials (or composites for short) are engineered materials made from two or more constituent materials with significantly different physical or chemical properties and which remain separate and distinct on a macroscopic level within the finished structure.

Background

The most primitive composite materials comprised straw and mud in the form of bricks for building construction; the Biblical book of Exodus speaks of the Israelites being oppressed by Pharaoh, by being forced to make bricks without straw. The ancient brick-making process can still be seen on Egyptian tomb paintings in the Metropolitan Museum of Art. The most advanced examples perform routinely on spacecraft in demanding environments. The most visible applications pave our roadways in the form of either steel and aggregate reinforced portland cement or asphalt concrete. Those composites closest to our personal hygiene form our shower stalls and bath tubs made of fiberglass. Solid surface, imitation granite and cultured marble sinks and counter tops are widely used to enhance our living experiences.

There are two categories of constituent materials: matrix and reinforcement. At least one portion of each type is required. The matrix material surrounds and supports the reinforcement materials by maintaining their relative positions. The reinforcements impart their special mechanical and physical properties to enhance the matrix properties. A synergism produces material properties unavailable from the individual constituent materials, while the wide variety of matrix and strengthening materials allows the designer of the product or structure to choose an optimum combination.

Engineered composite materials must be formed to shape. The matrix material can be introduced to the reinforcement before or after the reinforcement material is placed into the mold cavity or onto the mold surface. The matrix material experiences a melding event, after which the part shape is essentially set. Depending upon the nature of the matrix material, this melding event can occur in various ways such as chemical polymerization or solidification from the melted state.

A variety of molding methods can be used according to the end-item design requirements. The principal factors impacting the methodology are the natures of the chosen matrix and reinforcement materials. Another important factor is the gross quantity of material to be produced. Large quantities can be used to justify high capital expenditures for rapid and automated manufacturing technology. Small production quantities are accommodated with lower capital expenditures but higher labor and tooling costs at a correspondingly slower rate.

Most commercially produced composites use a polymer matrix material often called a resin solution. There are many different polymers available depending upon the starting raw ingredients. There are several broad categories, each with numerous variations. The most common are known as polyester, vinyl ester, epoxy, phenolic, polyimide, polyamide, polypropylene, PEEK, and others. The reinforcement materials are often fibers but also commonly ground minerals.

Molding methods

In general, the reinforcing and matrix materials are combined, compacted and processed to undergo a melding event. After the melding event, the part shape is essentially set, although it can deform under certain process conditions. For a thermoset polymeric matrix material, the melding event is a curing reaction that is initiated by the application of additional heat or chemical reactivity such as an organic peroxide. For a thermoplastic polymeric matrix material, the melding event is a solidification from the melted state. For a metal matrix material such as titanium foil, the melding event is a fusing at high pressure and a temperature near the melt point.

For many molding methods, it is convenient to refer to one mold piece as a "lower" mold and another mold piece as an "upper" mold. Lower and upper refer to the different faces of the molded panel, not the mold's configuration in space. In this convention, there is always a lower mold, and sometimes an upper mold. Part construction begins by applying materials to the lower mold. Lower mold and upper mold are more generalized descriptors than more common and specific terms such as male side, female side, a-side, b-side, tool side, bowl, hat, mandrel, etc. Continuous manufacturing processes use a different nomenclature.

The molded product is often referred to as a panel. For certain geometries and material combinations, it can be referred to as a casting. For certain continuous processes, it can be referred to as a profile.

Open molding

A process using a rigid, one sided mold which shapes only one surface of the panel. The opposite surface is determined by the amount of material placed upon the lower mold. Reinforcement materials can be placed manually or robotically. They include continuous fiber forms fashioned into textile constructions and chopped fiber. The matrix is generally a resin, and can be applied with a pressure roller, a spray device or manually. This process is generally done at ambient temperature and atmospheric pressure. Two variations of open molding are Hand Layup and Spray-up.

Vacuum bag molding

A process using a two-sided mold set that shapes both surfaces of the panel. On the lower side is a rigid mold and on the upper side is a flexible membrane. The flexible membrane can be a reusable silicone material or an extruded polymer film such as nylon. Reinforcement materials can be placed on the lower mold manually or robotically, generally as continuous fiber forms fashioned into textile constructions. The matrix is generally a resin. The fiber form may be pre-impregnated with the resin in the form of prepreg fabrics or unidirectional tapes. Otherwise, liquid matrix material is introduced to dry fiber forms prior to applying the flexible film. Then, vacuum is applied to the mold cavity. This process can be performed at either ambient or elevated temperature with ambient atmospheric pressure acting upon the vacuum bag. Most economical way is using a venturi vacuum and air compressor or a vacuum pump.

Autoclave molding

A process using a two-sided mold set that forms both surfaces of the panel. On the lower side is a rigid mold and on the upper side is a flexible membrane made from silicone or an extruded polymer film such as nylon. Reinforcement materials can be placed manually or robotically. They include continuous fiber forms fashioned into textile constructions. Most often, they are pre-impregnated with the resin in the form of prepreg fabrics or unidirectional tapes. In some instances, a resin film is placed upon the lower mold and dry reinforcement is placed above. The upper mold is installed and vacuum is applied to the mold cavity. Then, the assembly is placed into an autoclave pressure vessel. This process is generally performed at both elevated pressure and elevated temperature. The use of elevated pressure facilitates a high fiber volume fraction and low void content for maximum structural efficiency.

Resin transfer molding

A process using a two-sided mold set that forms both surfaces of the panel. The lower side is a rigid mold. The upper side can be a rigid or flexible mold. Flexible molds can be made from composite materials, silicone or extruded polymer films such as nylon. The two sides fit together to produce a mold cavity. The distinguishing feature of resin transfer molding is that the reinforcement materials are placed into this cavity and the mold set is closed prior to the introduction of matrix material. Resin transfer molding includes numerous varieties which differ in the mechanics of how the resin is introduced to the reinforcement in the mold cavity. These variations include everything from vacuum infusion to vacuum assisted resin transfer molding. This process can be performed at either ambient or elevated temperature.

Other

Other types of molding include press molding, transfer molding, pultrusion molding, filament winding, casting, centrifugal casting and continuous casting.

Tooling

Some types of tooling materials used in the manufacturing of composites structures include invar, steel, aluminum, reinforced silicon rubber, nickle, and carbon fiber. Selection of the tooling material is typically based on, but not limited to, the coefficient of thermal expansion, expected number of cycles, end item tolerance, desired or required surface condition, method of cure, glass transition temperature of the material being molded, molding method, matrix, cost and a variety of other considerations.

Mechanics of composite materials

The physical properties of composite materials are generally not isotropic in nature, but rather are typically orthotropic. For instance, the stiffness of a composite panel will often depend upon the directional orientation of the applied forces and/or moments. Panel stiffness is also dependent on the design of the panel. For instance, the fiber reinforcement and matrix used, the method of panel build, thermoset versus thermoplastic, type of weave, and orientation of fiber axis to the primary force.

In contrast, isotropic materials (for example, aluminum or steel), in standard wrought forms, typically have the same stiffness regardless of the directional orientation of the applied forces and/or moments.

The relationship between forces/moments and strains/curvatures for an isotropic material can be described with the following material properties: Young's Modulus, the Shear Modulus and the Poisson's ratio, in relatively simple mathematical relationships. For the anisotropic material, it requires the mathematics of a second order tensor and can require up to 21 material property constants. For the special case of orthogonal isotropy, there are three different material property constants for each of Young's Modulus, Shear Modulus and Poisson's Ratio for a total of nine material property constants to describe the relationship between forces/moments and strains/curvatures.

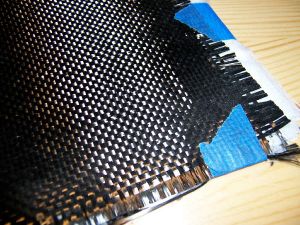

Categories of fiber reinforced composite materials

Fiber reinforced composite materials can be divided into two main categories normally referred to as short fiber reinforced materials and continuous fiber reinforced materials. Continuous reinforced materials will often constitute a layered or laminated structure. The woven and continuous fiber styles are typically available in a variety of forms, being pre-impregnated with the given matrix (resin), dry, uni-directional tapes of various widths, plain weave, harness satins, braided, and stitched.

The short and long fibers are typically employed in compression molding and sheet molding operations. These come in the form of flakes, chips, and random mate (which can also be made from a continuous fiber laid in random fashion until the desired thickness of the ply/laminate is achieved).

Failure of Composites

Shock, impact, or repeated cyclic stresses can cause the laminate to separate at the interface between two layers, a condition known as delamination. Individual fibers can separate from the matrix e.g. fiber pull-out.

Composites can fail on the microscopic or macroscopic scale. Compression failures can occur at both the macro scale or at each individual reinforcing fiber in compression buckling. Tension failures can be net section failures of the part or degradation of the composite at a microscopic scale where one or more of the layers in the composite fail in tension of the matrix or failure the bond between the matrix and fibers.

Some composites are brittle and have little reserve strength beyond the initial onset of failure while others may have large deformations and have reserve energy absorbing capacity past the onset of damage. The variations in fibers and matrices that are available and the mixtures that can be made with blends leave a very broad range of properties that can be designed into a composite structure.

Examples of composite materials

Fiber Reinforced Polymers or FRPs include Wood comprising (cellulose fibers in a lignin and hemicellulose matrix), Carbon-fiber reinforced plastic or CFRP, Glass-fiber reinforced plastic or GFRP (also GRP). If classified by matrix then there are Thermoplastic Composites, short fiber thermoplastics, long fiber thermoplastics or long fiber reinforced thermoplastics There are numerous thermoset composites, but advanced systems usually incorporate aramid fiber and carbon fiber in an epoxy resin matrix.

Composites can also utilize metal fibers reinforcing other metals, as in Metal matrix composites or MMC. Ceramic matrix composites include Bone (hydroxyapatite reinforced with collagen fibers), Cermet (ceramic and metal) and Concrete. Organic matrix/ceramic aggregate composites include Asphalt concrete, Mastic asphalt, Mastic roller hybrid, Dental composite, Syntactic foam and Mother of Pearl. Chobham armour is a special composite used in military applications.

Additionally, thermoplastic composite materials can be formulated with specific metal powders resulting in materials with a density range from two g/cc to 11 g/cc (same density as lead). These materials can be used in place of traditional materials such as aluminum, stainless steel, brass, bronze, copper, lead, and even tungsten in weighting, balancing, vibration dampening, and radiation shielding applications. High density composites are an economically viable option when certain materials are deemed hazardous and are banned (such as lead) or when secondary operations costs (such as machining, finishing, or coating) are a factor.

Engineered wood includes a wide variety of different products such as Plywood, Oriented strand board, Wood plastic composite (recycled wood fiber in polyethylene matrix), Pykrete (sawdust in ice matrix), Plastic-impregnated or laminated paper or textiles, Arborite, Formica (plastic) and Micarta. Other engineered laminate composites, such as Mallite, use a central core of end grain balsa wood, bonded to surface skins of light alloy or GRP. These generate low-weight, high rigidity materials.

Typical Products

Composite materials have gained popularity (despite their generally high cost) in high-performance products such as aerospace components (tails, wings , fuselages, propellors), boat and scull hulls, and racing car bodies. More mundane uses include fishing rods and storage tanks.

See also

ReferencesISBN links support NWE through referral fees

- Chawla, Krishan K. 2001. Composite Materials: Science and Engineering (Materials Research and Engineering). New York, NY: Springer. ISBN 0387984097

- Christensen, Richard M. 2005. Mechanics of Composite Materials. Mineola, NY: Dover Publications. ISBN 048644239X

- Jones, Robert. 1998. Mechanics Of Composite Materials, Second Edition (Materials Science & Engineering Series). Philadelphia, PA: Taylor & Francis. ISBN 156032712X

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.