Wind tunnel

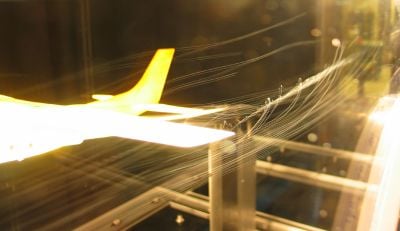

A wind tunnel is a research tool developed to assist with studying the effects of air moving over or around solid objects. The speed and flow of air in a wind tunnel can be measured in any of several ways. For instance, threads can be attached to the surface of study objects to detect flow direction and relative speed of air flow. Alternatively, dye or smoke can be injected upstream into the air stream and the streamlines followed by the dye particles can be photographed as the experiment proceeds. Also, pitot tube probes can be inserted in the air flow to measure static and dynamic air pressure.

History

English military engineer and mathematician Benjamin Robins (1707–1751) invented a whirling arm apparatus to determine drag and did some of the first experiments in aviation theory.

Sir George Cayley (1773-1857), the "father of aerodynamics," also used a whirling arm to measure the drag and lift of various airfoils. His whirling arm was five feet long and attained top speeds between ten and 20 feet per second. Armed with test data from the arm, Cayley built a small glider that is believed to have been the first successful heavier-than-air vehicle to carry a man in history.

However, the whirling arm does not produce a reliable flow of air impacting the test shape at a normal incidence. Centrifugal forces and the fact that the object is moving in its own wake mean that detailed examination of the airflow is difficult. Francis Herbert Wenham (1824-1908), a Council Member of the Aeronautical Society of Great Britain, addressed these issues by inventing, designing, and operating the first enclosed wind tunnel in 1871. Wenham's tunnel had a fan-blower, driven by a steam engine, which propelled air down the tube to the model.[1]

Once this breakthrough had been achieved, detailed technical data was rapidly extracted by the use of this tool. Wenham and his colleague Browning are credited with many fundamental discoveries, including the measurement of l/d ratios, and the revelation of the beneficial effects of a high aspect ratio.

Carl Rickard Nyberg used a wind tunnel when designing his Flugan from 1897 and onwards.

In a classic set of experiments, the Englishman Osborne Reynolds (1842-1912) of the University of Manchester demonstrated that the airflow pattern over a scale model would be the same for the full-scale vehicle if a certain flow parameter were the same in both cases. This factor, now known as the Reynolds Number, is a basic parameter in the description of all fluid-flow situations, including the shapes of flow patterns, the ease of heat transfer, and the onset of turbulence. This comprises the central scientific justification for the use of models in wind tunnels to simulate real-life phenomena.

The Wright brothers' use of a simple wind tunnel in 1901 to study the effects of airflow over various shapes while developing their Wright Flyer was in some ways revolutionary. It can be seen from the above, however, that they were simply using the accepted technology of the day, though this was not yet a common technology in America.

Subsequent use of wind tunnels proliferated as the science of aerodynamics and discipline of aeronautical engineering were established and air travel and power were developed.

Wind tunnels were often limited in the volume and speed of airflow which could be delivered.

The wind tunnel used by German scientists at Peenemünde prior to and during WWII is an interesting example of the difficulties associated with extending the useful range of large wind tunnels. It used some large natural caves which were increased in size by excavation and then sealed to store large volumes of air which could then be routed through the wind tunnels. This innovative approach allowed lab research in high speed regimes and greatly accelerated the rate of advance of Germany's aeronautical engineering efforts.

Later research into airflows near or above the speed of sound used a related approach. Metal pressure chambers were used to store high pressure air which was then accelerated through a nozzle designed to provide supersonic flow. The observation or instrumentation chamber was then placed at the proper location in the throat or nozzle for the desired airspeed.

For limited applications, Computational fluid dynamics (CFD) can augment or possibly replace the use of wind tunnels. For example, the experimental rocket plane SpaceShipOne was designed without any use of wind tunnels. However, on one test, flight threads were attached to the surface of the wings, performing a wind tunnel type of test during an actual flight in order to refine the computational model. It should be noted that, for situations where external turbulent flow is present, CFD is not practical due to limitations in present day computing resources. For example, an area that is still much too complex for the use of CFD is determining the effects of flow on and around structures, bridges, terrain, etc.

The most effective way to simulative external turbulent flow is through the use of a boundary layer wind tunnel.

There are many applications for boundary layer wind tunnel modeling. For example, understanding the impact of wind on high-rise buildings, factories, bridges, etc. can help building designers construct a structure that stands up to wind effects in the most efficient manner possible. Another significant application for boundary layer wind tunnel modeling is for understanding exhaust gas dispersion patterns for hospitals, laboratories, and other emitting sources. Other examples of boundary layer wind tunnel applications are assessments of pedestrian comfort and snow drifting. Wind tunnel modeling is accepted as a method for aiding in Green building design. For instance, the use of boundary layer wind tunnel modeling can be used as a credit for Leadership in Energy and Environmental Design (LEED) certification through the U.S. Green Building Council.

Wind tunnel tests in a boundary layer wind tunnel allow for the natural drag of the earth's surface to be simulated. For accuracy, it is important to simulate the mean wind speed profile and turbulence effects within the atmospheric boundary layer. Most codes and standards recognize that wind tunnel testing can produce reliable information for designers, especially when their projects are in complex terrain or on exposed sites.

How it works

Air is blown or sucked through a duct equipped with a viewing port and instrumentation where models or geometrical shapes are mounted for study. Typically the air is moved through the tunnel using a series of fans. For very large wind tunnels several meters in diameter, a single large fan is not practical, and so instead an array of multiple fans are used in parallel to provide sufficient airflow. Due to the sheer volume and speed of air movement required, the fans may be powered by stationary turbofan engines rather than electric motors.

The airflow created by the fans that is entering the tunnel is itself highly turbulent due to the fan blade motion, and so is not directly useful for accurate measurements. The air moving through the tunnel needs to be relatively turbulence-free and laminar. To correct this problem, a series of closely-spaced vertical and horizontal air vanes are used to smooth out the turbulent airflow before reaching the subject of the testing.

Due to the effects of viscosity, the cross-section of a wind tunnel is typically circular rather than square, because there will be greater flow constriction in the corners of a square tunnel that can make the flow turbulent. A circular tunnel provides a much smoother flow.

The inside facing of the tunnel is typically very smooth to reduce surface drag and turbulence that could impact the accuracy of the testing. Even smooth walls induce some drag into the airflow, and so the object being tested is usually kept near the center of the tunnel, with an empty buffer zone between the object and the tunnel walls.

Lighting is usually recessed into the circular walls of the tunnel and shines in through windows. If the light were mounted on the inside surface of the tunnel in a conventional manner, the light bulb would generate turbulence as the air blows around it. Simarly, observation is usually done through transparent portholes into the tunnel. Rather than simply being flat discs, these lighting and observation windows may be curved to match the cross-section of the tunnel and further reduce turbulence around the window.

Various techniques are used to study the actual airflow around the geometry and compare it with theoretical results, which must also take into account the Reynolds number and Mach number for the regime of operation.

Pressure measurements

Pressure across the surfaces of the model can be measured if the model includes pressure taps. This can be useful for pressure-dominated phenomena, but this only accounts for normal forces on the body.

Force and moment measurements

With the model mounted on a force balance, one can measure lift, drag, lateral forces, yaw, roll, and pitching moments over a range of angle of attack. This allows one to produce common curves such as lift coefficient versus angle of attack (shown).

Note that the force balance itself creates drag and potential turbulence that will affect the model and introduce errors into the measurements. The supporting structures are therefore typically smoothly shaped to minimize turbulence.

Flow visualization

Because air is transparent it is difficult to directly observe the air movement itself. Instead, a smoke particulate or a fine mist of liquid is sprayed into the tunnel just ahead of the device being tested. The particulate is sufficiently low mass to stay suspended in the air without falling to the floor of the tunnel, and is light enough to easily move with the airflow.

If the air movement in the tunnel is sufficiently non-turbulent, a particle stream released into the airflow will not break up as the air moves along, but stays together as a sharp thin line. Multiple particle streams released from a grid of many nozzles can provide a dynamic three-dimensional shape of the airflow around the object being tested. As with the force balance, these injection pipes and nozzles need to be shaped in a manner that minimizes the introduction of turbulent airflow into the airstream.

High-speed turbulence and vortices can be difficult to see directly, but strobe lights and film cameras or high-speed digital cameras can help to capture events that are a blur to the naked eye.

High-speed cameras are also required when the subject of the test is itself moving at high speed, such as an airplane propeller. The camera can capture stop-motion images of how the blade cuts through the particulate streams and how vortices are generated along the trailing edges of the moving blade.

Classification

There are many different kinds of wind tunnels. They are typically classified by the range of speeds that are achieved in the test section, as follows:

- Low-speed wind tunnel

- High speed wind tunnel

- Subsonic and transonic wind tunnel

- Supersonic wind tunnel

- Hypersonic wind tunnel

- High enthalpy wind tunnel

Wind tunnels are also classified by the orientation of air flow in the test section with respect to gravity. Typically they are oriented horizontally, as happens during level flight. A different class of wind tunnels are oriented vertically so that gravity can be balanced by drag instead of lift, and these have become a popular form of recreation for simulating sky-diving:

- Vertical wind tunnel

Wind tunnels are also classified based on their main use. For those used with land vehicles such as cars and trucks the type of floor aerodynamics is also important. These vary from stationary floors through to full moving floors, with smaller moving floors and some attempt at boundary level control also being important.

Aeronautical wind tunnels

The main subcategories in the aeronautical wind tunnels are:

High Reynolds number tunnels

Reynolds number is one of the governing similarity parameters for the simulation of flow in a wind tunnel. For mach number less than 0.3, it is the primary parameter that governs the flow characteristics. There are three main ways to simulate high Reynolds number, since it is not practical to obtain full scale Reynolds number by use of a full scale vehicle.

- Pressurised tunnels: Here test gases are pressurised to increase the Reynolds number.

- Heavy gas tunnels: Heavier gases like freon and R-134a are used as test gases. The transonic dynamics tunnel at NASA Langley is an example of such a tunnel.

- Cryogenic tunnels: Here test gas is cooled down to increase the Reynolds number. The European transonic wind tunnel uses this technique.

- High-altitude tunnels: These are designed to test the effects of shock waves against various aircraft shapes in near vacuum. In 1952 the University of California constructed the first two high-altitude wind tunnels: one for testing objects at 50 to 70 miles above the earth and the second for tests at 80 to 200 miles above the earth.[2]

V/STOL tunnels

V/STOL tunnels require large cross section area, but only small velocities. Since power varies with the cube of velocity, the power required for the operation is also less. An example of a V/STOL tunnel is the NASA Langley 14' x 22' tunnel.[3]

Spin tunnels

Aircraft have a tendency to go to spin when they stall. These tunnels are used to study that phenomenon.

Automotive tunnels

Automotive wind tunnels fall into two categories:

- External flow tunnels are used to study the external flow through the chassis

- Climatic tunnels are used to evaluate the performance of door systems, braking systems, etc. under various climatic conditions. Most of the leading automobile manufacturers have their own climatic wind tunnels

For external flow tunnels various systems are used to compensate for the effect of the boundary layer on the road surface, including systems of moving belts under each wheel and the body of the car (5 or 7 belt systems) or one large belt under the entire car, or other methods of boundary layer control such as scoops or perforations to suck it away.

Aeroacoustic tunnels

These tunnels are used in the studies of noise generated by flow and its suppression.

High enthalpy

A high enthalpy wind tunnel is intended to study flow of air around objects moving at speeds much faster than the local speed of sound (hypersonic speeds). "Enthalpy" is the total energy of a gas stream, composed of internal energy due to temperature, the product of pressure and volume, and the velocity of flow. Duplication of the conditions of hypersonic flight requires large volumes of high-pressure, heated air; large pressurized hot reservoirs, and electric arcs, are two techniques used.[4]

Aquadynamic flume

The aerodynamic principles of the wind tunnel work equally on watercraft, except the water is more viscous and so sets greater forces on the object being tested. A looping flume is typically used for underwater aquadynamic testing. The interaction between two different types of fluids means that pure wind tunnel testing is only partly relevant. However, a similar sort of research is done in a towing tank.

Low-speed oversize liquid testing

Air is not always the best test medium for studying small-scale aerodynamic principles, due to the speed of the air flow and airfoil movement. A study of fruit fly wings designed to understand how the wings produce lift was performed using a large tank of mineral oil and wings 100 times larger than actual size, in order to slow down the wing beats and make the vortices generated by the insect wings easier to see and understand.

Fan testing

Wind tunnel tests are also performed to precisely measure the air movement of fans at a specific pressure. By determining the environmental circumstances during measurement, and by revising the air-tightness afterwards, the standardization of the data is ensured.

There are two possible ways of measurement: a complete fan, or an impeller on a hydraulic installation. Two measuring tubes enable measurements of lower air currents (< 30,000 m3/h) as well as higher air currents (< 60,000 m3/h). The determination of the Q/h curve of the fan is one of the main objectives. To determine this curve (and to define other parameters) air technical, mechanical as well as electro technical data are measured:

Air technical:

- Static pressure difference (Pa)

- Amount of moved air (m3/h)

- Average air speed (m/s)

- Specific efficiency (W/1000 m3/h)

- Efficiency

Electro technical:

- Tension (V)

- Current (A)

- Cos φ

- Admitted power (W) fan / impeller

- Rotations per minute (RPM)

The measurement can take place on the fan or in the application in which the fan is used.

Wind engineering testing

In wind engineering, wind tunnel tests are used to measure the velocity around, and forces or pressures upon structures.[5] Very tall buildings, buildings with unusual or complicated shapes (such as a tall building with a parabolic or a hyperbolic shape), cable suspension bridges or cable stayed bridges are analyzed in specialized atmospheric boundary layer wind tunnels. These feature a long upwind section to accurately represent the wind speed and turbulence profile acting on the structure. Wind tunnel tests provide the necessary design pressure measurements in use of the dynamic analysis and control of tall buildings.[6]

Notes

- ↑ Donald D. Baals and William R. Corliss, Wind Tunnels of Nasa (NASA, 1981).

- ↑ "Windless Wind Tunnels for High Altitude Tests." Popular Mechanics, February 1952, 105. Retrieved January 19, 2022.

- ↑ 14'x22' Subsonic Wind Tunnel NASA. Retrieved January 19, 2022.

- ↑ Committee on Assessment of National Aeronautical Wind Tunnel Facilities, Review of Aeronautical Wind Tunnel Facilities (Washington DC: National Academy Press, 1988), 34–37. Retrieved January 19, 2022.

- ↑ Bruno Chanetz, A century of wind tunnels since Eiffel Comptes Rendus Mécanique 345(8) (2017): 581-594. Retrieved January 19, 2022.

- ↑ Aly Mousaad Aly, Alberto Zasso, and Ferruccio Resta, Dynamics and Control of High-Rise Buildings under Multidirectional Wind Loads Smart Materials Research (2011): 1–15. Retrieved January 19, 2022.

ReferencesISBN links support NWE through referral fees

- Anton, Philip S. Wind Tunnel and Propulsion Test Facilities: An Assessment of NASA's Capabilities to Serve National Needs. Santa Monica, CA: RAND Corporation, 2004. ISBN 0833035908

- Baals, Donald D., and William R. Corliss. Wind Tunnels of Nasa. NASA, 1981. ASIN B000NYKX3W

- Barlow, Jewel B., William H. Rae, and Alan Pope. Low-Speed Wind Tunnel Testing. Hoboken, NJ: Wiley-Interscience, 1999. ISBN 0471557749

- Goethert, Bernhard H. Transonic Wind Tunnel Testing. New York, NY: Dover Publications, 2007. ISBN 0486458814

External links

All links retrieved May 15, 2023.

- Boundary Layer Wind Tunnel University of Western Ontario

- Wind Tunnel Models Aeronautical Testing Service, Inc.

- Oran W. Nicks Low-Speed Wind Tunnel (TAMU LSWT) Texas A&M Wind Tunnel

- Climatic Wind Tunnel Vienna Rail Tec Arsenal (RTA)

- Theodore von Kármán Wind Tunnel Laboratory Budapest University of Technology and Economics (BME)

- The List of Wind Tunnel Testing Facilities Dewesoft

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.