Air bag

An air bag, also known as an Air Cushion Restraint System (ACRS) or Supplemental Restraint System (SRS), is an automobile safety device that automatically inflates upon collision to protect the riders from serious injury.[1] The gas-filled bag, classified as a passive restraint, acts as a cushion that prevents the occupants from striking against hard objects such as the steering wheel and dashboard.

Air bags are designed to complement conventional restraints, such as seat belts and seatbelt pre-tensioners, not replace them. Other passive safety features in an automobile may include "anti-submarine" seats, telescopically collapsible steering columns, "breakaway" control pedals (accelerator, brake, and clutch), and toughened or laminated glass.

A number of injuries and even fatalities have been associated with air bag deployment. However, most air bag-related deaths have involved occupants who have been unrestrained or improperly restrained. The combined use of an air bag and seat belt has been found to reduce the risk of serious head injury by 83 percent.[2] A recent study found that about 6,000 lives had been saved by the deployment of air bags.[3]

History

Invention

John W. Hetrick of Newport, Pennsylvania, (U.S.) invented the air bag in 1952, and patented his device in 1953. Hetrick came up with the idea to help protect his own family using expertise from his naval engineering days.[4] Over the years, the saving of many lives has been attributed to Hetrick's invention, and highlighted in television shows such as Nova on PBS. He also won various awards, including the Golden Gear award. Devices similar to airbags were introduced for airplanes as early as the 1940s, with the first patents filed for them in 1958.

Early air bag systems were air-filled bladders. These systems were large and bulky, and consisted primarily of compressed or heated air, compressed nitrogen gas (N2), freon, carbon dioxide (CO2), or a mixture of water and potassium (KH2O).[5]

American inventor Allen K. Breed then developed a key component for automotive use: The ball-in-tube sensor for crash detection. He marketed this innovation first in 1967 to Chrysler. A similar "Auto-Ceptor" crash-restraint, developed by Eaton, Yale & Towne Inc. for Ford was soon offered as an automatic safety system in the U.S., while the Italian Eaton-Livia company offered a variant with localized air cushions.[6]

First automotive applications: An alternative to the seatbelt

Air bags for passenger cars were introduced in the United States in the mid-1970s, when seat belt usage was not prevalent. Air bags were generally considered a convenient alternative to seat belts, while offering similar levels of protection to unbelted occupants in a head-on collision.

Ford built an experimental fleet of cars with air bags in 1971, followed by General Motors in 1973 on Chevrolet vehicles. In 1974, General Motors (GM) applied the technology to other brands, such as Buick, Cadillac, and Oldsmobile. GM offered dual air bags with two-stage deployment[7] and called them the "Air Cushion Restraint System".[8] The early fleet of experimental GM vehicles equipped with air bags experienced seven fatalities, one of which was later suspected to have been caused by the air bag.

The development of air bags coincided with an international interest in automobile safety legislation. Some safety experts cautioned against mandating a particular technical solution (rather than a general occupancy safety standard) that could rapidly date out and might not be a cost-effective approach. Motor manufacturers favored one standard over another, which could not easily be changed. As countries successively mandated seat belt restraints, there was less emphasis placed on other designs for several decades.[6]

Rebirth: Supplemental restraint

Car designers have moved on from the initial view of the air bag as a seat belt replacement. Automobile air bags are now designed and marketed as Supplemental Restraint Systems (SRS).

In 1980, Mercedes-Benz reintroduced the air bag in Germany that it had patented in 1971, as an option on its high-end S-Class (W126), which also offered other exotic options such as hydropneumatic suspension. In the Mercedes system, the sensors would tighten the seat belts and then deploy the air bag on impact. The air bag was thus no longer marketed as a means of avoiding seat belts, but as a way to obtain an extra margin of occupant safety.

In 1987, the Porsche 944 turbo became the first car in the world to have driver and passenger air bags as standard equipment. The Porsche 944 and 944S had this as an available option. This year also saw the first air bag in a Japanese car, the Acura Legend.

Audi was relatively late to offer air bag systems on a broader scale; until the 1994 model year, for example, the 80/90, by far Audi's "bread-and-butter" model, as well as the 100/200, did not have air bags in their standard versions. Instead, the German automaker until then relied solely on its proprietary procon-ten restraint system.

Air bags became common in the 1980s, with Chrysler and Ford introducing them in the mid-1980s. The former made them standard equipment across its entire line in 1990.

In Europe, air bags were almost unheard of on family cars until the early 1990s. The first European Ford to feature an air bag was the facelifted Escort MK5b in 1992; within a year, the entire Ford range had at least one air bag as standard. By the mid 1990s, European market leaders such as Vauxhall/Opel, Rover, Peugeot, Renault, and Fiat had included air bags as at least optional equipment across their model ranges. By the end of the decade, it was very rare to find a mass market car without an air bag, and some late 1990s products, such as the Volkswagen Golf Mk4 also featured side air bags. The Peugeot 306 was a classic example of how commonplace air bags became on mass market cars during the 1990s. On its launch in early 1993, most of the range did not even have driver air bags as an option. By 1999 however, side air bags were available on several variants.

During the 2000s, side air bags were commonplace on even budget cars, such as the smaller-engined versions of the Ford Fiesta and Peugeot 206, and curtain air bags were also becoming regular features on mass market cars. The Toyota Avensis, launched in 1998, was the first mass market car to be sold in Europe with a total of nine air bags.

Air bags become mandatory

On July 11, 1984, the U.S. government required cars being produced after April 1, 1989, to have driver's side air bags or automatic seat belts. (The automatic seat belt was a technology, now discarded, that "forced" motorists to wear seat belts.) Air bag introduction was stimulated by the U.S. DOT.[9]

In 1998, dual front air bags were mandated by the National Highway Traffic Safety Administration (NHTSA), and de-powered, or second-generation air bags were also mandated. This was due to the injuries caused by first-generation air bags that were designed to be powerful enough to restrain people who were not wearing seat belts.

In the United Kingdom and most other developed countries, there is no direct legal requirement for new cars to feature air bags. Instead, the Euro NCAP vehicle safety rating encourages manufacturers to take a comprehensive approach to occupant safety; a good rating can only be achieved by combining air bags with other safety features.[10] Thus almost all new cars now come with at least two air bags as standard.

Side-impact air bags

Side-impact air bags are a category of air bag usually located in the seat, and inflate between the seat occupant and the door.

These are specifically designed to reduce the risk of injury to the pelvis and lower abdomen. Some vehicles are now being equipped with a different types of designs, to help reduce injury and ejection from the vehicle in rollover crashes.

The Swedish company Autoliv AB, was granted a patent on side air bags, and they were first offered as an option on the 1995 model year Volvo 850, and as standard equipment on all Volvo cars made after 1995. The first "head protection" air bags were included as standard equipment in the model year 1998 BMW 7-series and E39 5-series.

In late 1997, the BMW 7-series and E39 5-series were fitted with head side air bags, the "Head Protection System (HPS)." This is an industry's first in offering head protection to the front seat passengers in side impact collisions.[11] This air bag will maintain inflation for up to seven seconds for rollover protection. However, this tubular-shaped air bag is replaced by a inflatable "curtain" air bags for superior protection.

In 1998, the Volvo S80 was first given curtain air bags to protect both front and rear passengers. They were then made standard equipment on all new Volvo cars from 1998. The Volvo Curtain Airbag design is now considered to be superior by most car manufacturers and is the one mostly used; in some cars it has been designed to stay inflated for rollover crashes.

The many SUVs and MPVs have a long inflatable curtain air bag that protects all 3 rows of seats manufactured in recent years.

Curtain air bags have been said to reduce brain injury or fatalities by up to 45 percent in a side impact with an SUV. These air bags come in various forms (e.g., tubular, curtain, door-mounted) depending on the needs of the application.[12]

Motorcycle air bags

In 2006 Honda introduced the first motorcycle air bag safety system on its Gold Wing motorcycle.

Dual-stage air bags

Many advanced air bag technologies are being developed to tailor air bag deployment to the severity of the crash, the size and posture of the vehicle occupant, belt usage, and how close that person is to the actual air bag. Many of these systems use multi-stage inflators that deploy less forcefully in stages in moderate crashes than in very severe crashes. Occupant sensing devices let the air bag control unit know if someone is occupying a seat adjacent to an air bag, the mass/weight of the person, whether a seat belt or child restraint is being used, and whether the person is forward in the seat and close to the air bag. Based on this information and crash severity information, the air bag is deployed at either a high force level, a less forceful level, or not at all.

Adaptive air bag systems may utilize multi-stage air bags to adjust the pressure within the air bag. The greater the pressure within the air bag, the more force the air bag will exert on the occupants as they come in contact with it. These adjustments allow the system to deploy the air bag with a moderate force for most collisions; reserving the maximum force air bag only for severest of collisions. Additional sensors to determine the location, weight or relative size of the occupants may also be used. Information regarding the occupants and the severity of the crash are used by the air bag control unit, to determine whether air bags should be suppressed or deployed, and if so, at various output levels.

How air bags work

The design is conceptually simple; a central "air bag control unit"[13] (ACU) (a specific type of ECU) monitors a number of related sensors within the vehicle, including accelerometers, impact sensors, wheel speed sensors, gyroscopes, brake pressure sensors, and seat occupancy sensors. When the requisite "threshold" has been reached or exceeded, the air bag control unit will trigger the ignition of a gas generator propellant to rapidly inflate a nylon fabric bag. The inflated air bag reduces the deceleration experienced by the passenger during the crash through the process of venting gas out of small vent holes in a controlled manner absorbing the energy of the occupant impacting the bag. The air bag's volume and the size of the vents in the bag are tailored to each vehicle type, to dissipate the occupant's energy over time and distribute the deceleration forces across a larger portion of the occupant's body (compared to a seat belt alone).

The different signals from the various sensors are fed into the air bag control unit, and this determines the angle of impact, the severity, or force of the crash, along with other variables. Depending on the result of these calculations, the ACU may also deploy various additional restraint devices, such as seat belt pre-tensioners, seat-mounted side bags, and "curtain" air bags that cover the side glass.

Each restraint device is typically activated with one or more pyrotechnic devices, commonly called an initiator or electric match. The electric match, which consists of an electrical conductor wrapped in a combustible material, activates with a current pulse between 1 to 3 amperes in less than 2 milliseconds. When the conductor becomes hot enough, it ignites the combustible material, which initiates the gas generator. In a seat belt pre-tensioner, this hot gas is used to drive a piston that pulls the slack out of the seat belt. In an air bag, the initiator is used to ignite solid propellant inside the air bag inflator. The burning propellant generates inert gas that rapidly inflates the air bag in approximately 20 to 30 milliseconds.

An air bag must inflate quickly in order to be fully inflated by the time the forward-traveling occupant reaches its outer surface. Typically, the decision to deploy an air bag in a frontal crash is made within 15 to 30 milliseconds after the onset of the crash, and both the driver and passenger air bags are fully inflated within approximately 60-80 milliseconds after the first moment of vehicle contact. If an air bag deploys too late or too slowly, the risk of occupant injury from contact with the inflating air bag may increase. Since more distance typically exists between the passenger the instrument panel, the passenger air bag is larger and requires more gas to fill it.

Front air bags normally do not protect the occupants during side, rear, or rollover accidents.[14] Since air bags deploy only once and deflate quickly after the initial impact, they will not be beneficial during a subsequent collision. Safety belts help reduce the risk of injury in many types of crashes. They help to properly position occupants to maximize the air bag's benefits and they help restrain occupants during the initial and any subsequent collisions.

In vehicles equipped with a rollover sensing system, accelerometers and gyroscopes are used to sense the onset of a rollover event. If a rollover event is determined to be imminent, side-curtain air bags are deployed to help protect the occupant from contact with the side of the vehicle interior, and also to help prevent occupant ejection as the vehicle rolls over.

Triggering conditions

Air bags are designed to deploy in frontal and near-frontal collisions that are more violent than a 23 km/h (14 mph) barrier collision, or similarly, striking a parked car of similar size across the full front of each vehicle at about twice the speed. (The parked car absorbs some of the energy of the crash.)

Unlike crash tests into barriers, real-world crashes typically occur at angles, and the crash forces usually are not evenly distributed across the front of the vehicle. Consequently, the relative speed between a striking and struck vehicle required to deploy the air bag in a real-world crash can be much higher than an equivalent barrier crash. Because air bag sensors measure deceleration, vehicle speed and damage are not good indicators of whether an air bag should have deployed. Air bags can deploy due to the vehicle's undercarriage striking a low object protruding above the roadway due to the resulting deceleration.

The air bag sensor is a MEMS accelerometer, which is a small integrated circuit with integrated micro-mechanical elements. The microscopic mechanical element moves in response to rapid deceleration, and this motion causes a change in capacitance, which is detected by the electronics on the chip that then sends a signal to fire the air bag. The most common MEMS accelerometer in use is the ADXL-50 by Analog Devices, but there are other MEMS manufacturers as well.

Nearly all air bags are designed to automatically deploy in the event of a vehicle fire, when temperatures reach 150-200 °C (300-400 °F). This safety feature, often termed auto-ignition, helps to ensure that such temperatures do not cause an explosion of the entire air bag module.

Today, air bag triggering algorithms are becoming much more complex. They try to reduce unnecessary deployments (for example, at low speed, no shocks should trigger the air bag, to help reduce damage to the car interior, under conditions in which the seat belt would be an adequate safety device), and to adapt the deployment speed to the crash conditions. The algorithms are considered valuable intellectual property. Experimental algorithms may take into account such factors as the weight of the occupant, the seat location, seatbelt use, and even attempt to determine if a baby seat is present.

Inflation

When the frontal air bags are to deploy, a signal is sent to the inflater unit within the air bag control unit. An igniter starts a rapid chemical reaction generating primarily nitrogen gas (N2) to fill the air bag making it deploy through the module cover. Some air bag technologies use compressed nitrogen or argon gas with a pyrotechnic operated valve ("hybrid gas generator"), while other technologies use various energetic propellants. Propellants containing sodium azide (NaN3) were common in early inflator designs. However, sodium azide is highly toxic, and propellants containing this compound were phased out during the 1990s in pursuit of more efficient, less expensive and less toxic alternatives.

Alternative propellants may incorporate, for example, a combination of nitroguanidine, phase-stabilized ammonium nitrate (NH4NO3) or other nonmetallic oxidizer, and a nitrogen-rich fuel other than azide (such as tetrazoles, triazoles, and their salts). The burn rate modifiers in the mixture may be an alkaline metal nitrate (NO3-) or nitrite (NO2-), dicyanamide or its salts, sodium borohydride (NaBH4), and so forth. The coolants and slag formers may be clay, silica, alumina, or glass.[15] Other alternatives are, for instance, nitrocellulose-based propellants (which have high gas yield but bad storage stability, and their oxygen balance requires secondary oxidation of the reaction products to avoid buildup of carbon monoxide), or high-oxygen nitrogen-free organic compounds with inorganic oxidizers (for example, di or tricarboxylic acids with chlorates (ClO3-) or perchlorates (HClO4) and eventually metallic oxides. The nitrogen-free formulation avoids formation of toxic nitrogen oxides).

From the onset of the crash, the entire deployment and inflation process is about 0.05 seconds faster than the blink of an eye (about 0.2 seconds). Because vehicles change speed so quickly in a crash, air bags must inflate rapidly to reduce the risk of the occupant hitting the vehicle's interior.

Post-deployment

Once an air bag deploys, deflation begins immediately, as the gas escapes through vent(s) in the fabric and cools. Deployment is frequently accompanied by the release of dust-like particles and gases (called effluent) in the vehicle's interior. Most of this dust consists of cornstarch, french chalk, or talcum powder, which are used to lubricate the air bag during deployment. Newer designs produce effluent primarily consisting of harmless talcum powder/cornstarch and nitrogen gas (about 80 percent of the air we breathe is nitrogen). In older designs using an azide-based propellant (usually NaN3), varying amounts of sodium hydroxide (NaOH) are nearly always present initially. In small amounts this chemical can cause minor irritation to the eyes and/or open wounds; however, with exposure to air, it quickly turns into sodium bicarbonate (baking soda). However, this transformation is not 100 percent complete, and invariably leaves residual amounts of hydroxide ion from NaOH. Depending on the type of air bag system, potassium chloride may also be present.

For most people, the only effect the dust may produce is some minor irritation of the throat and eyes. Generally, minor irritations occur only when the occupant remains in the vehicle for many minutes with the windows closed and no ventilation. However, some people with asthma may develop an asthmatic attack from inhaling the dust. With the onset of symptoms, asthmatics should treat themselves as advised by their doctor, then immediately seek medical treatment.

Benefits

Air bags supplement the safety belt by reducing the chance that the occupant's head and upper body will strike some part of the vehicle's interior. They also help reduce the risk of serious injury by distributing crash forces more evenly across the occupant's body. Curtain air bags help keep all parts of the occupant inside the vehicle.

A recent study found that about 6,000 lives had been saved by the deployment of air bags.[3]

Costs

Air bags cost about $500 (USD) per vehicle from original equipment manufacturers (OEMs), who typically pay the supplier less than $100. If the air bags are deployed or stolen, the registered vehicle owner is required to replace them. Since they are an integral part of the vehicle design, air bags are not commonly retrofitted to a vehicle that does not have them.

Most manufacturers specify the replacement of undeployed air bags after a certain period to ensure their reliability in an accident.

Although self installation of used or surplus components may result in considerable cost savings, air bags should only be serviced by those who are properly qualified. Accidental deployment while servicing could result in severe injury, and an improperly installed or defective air bag unit may not provide sufficient protection in an accident. For these reasons, laws limiting sale, shipping, handling and maintenance have been imposed in several countries. In Germany, where some of the strictest laws are in place, air bags count as harmful explosives, and only car mechanics with additional special training are allowed to service air bag systems. Under German Federal Law, used but intact air bags are to be detonated under secure conditions, and must not be passed on to third parties in any way, and private (that is, layman) individuals are not allowed to handle air bags under any circumstances. Legal purchase is restricted to buying a new replacement unit for immediate installation by the seller's qualified personnel.

Air bag injuries and fatalities

Although air bags can protect a person under the right circumstances, they can also injure or even kill. The benefit of an air bag is maximized for people who have buckled up their seat belts and have kept children (12 and under) in rear seats, also buckled up. According to the NHTSA, nearly all air bag-related deaths have involved occupants who have been unrestrained or improperly restrained. The combined use of an air bag and seat belt has been found to reduce the risk of serious head injury by 83 percent.[16]

To protect occupants not wearing seat belts, air bags designed in the U.S. trigger much more quickly than those designed in other countries. As seat belt use in the U.S. climbed in the late 1980s and early 1990s, auto manufactures were able to adjust their designs. Today, all air bag control units recognize if a belt is used, and set the trigger time accordingly.[17]

Newer air bag designs trigger at a lower speed; nonetheless, occupants are strongly advised to remain at least 25 centimeters (10 in) from the panel from which frontal air bags deploy, to avoid injury from the bag in a crash.[18] While driving, a driver must be seated so that the center of the chest remains 25 centimeters (10 in) from the center of the steering wheel hub. The design of side air bags means occupants of a vehicle must not lean against the inside of the car window or doors, the pillars or place objects between themselves and the side of the vehicle.

Deployment of an air bag may cause injuries, especially when the occupants are not properly restrained with seat belts. Injuries include abrasion of the skin, hearing damage (from the sound during deployment), head injuries, eye damage for spectacle wearers, and fractures of the nose, fingers, hands, or arms. The occupant may also sustain burn injuries, such as: Chemical burns (from contact with sodium hydroxide present in the aerosol), thermal burns (from hot gases in the air bag), and friction burns (from physical friction).[19]

Improvements in sensing and gas generator technology have allowed the development of second generation air bag systems that can adjust their deployment parameters to size, weight, position and restraint status of the occupant. These improvements have demonstrated a reduced injury risk factor for small adults and children who had an increased risk of injury with first generation air bag systems.[20]

Safe use of air bags

An unrestrained or improperly restrained occupant can be seriously injured or killed by a deploying air bag. The NHTSA recommends drivers sit with at least 25 cm (10") between the center of their breastbone and the center of the steering wheel. Children under the age of 13 years should always be properly restrained in a rear seat.[21] A rear-facing infant restraint must never be put in the front seat of a vehicle with a front passenger air bag. A rear-facing infant restraint places an infant's head close to the air bag, which can cause severe head injuries, or death if the air bag deploys. Some modern cars include a switch to disable the front passenger air bag, (although not in Australia, where rear-facing child seats must not be used in the front where an air bag is fitted), in case a child-supporting seat is used there.

One should avoid smoking a pipe when driving. An inflating air bag would hit the pipe, possibly leading to a fatality, even if the crash were moderate.

Aerospace and military applications

The aerospace industry and the U.S. Government have applied air bag technologies for many years. NASA and the United States Department of Defense incorporated air bag systems in various aircraft and spacecraft applications as early as the 1960s.

Air bag landing systems

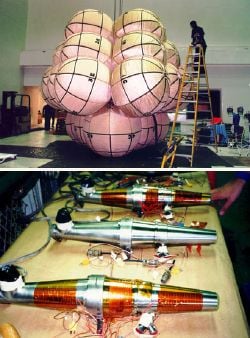

The first use of air bags for landing were with Luna 9 and Luna 13, which landed on the Moon in 1966 and returned panoramic images. The Mars Pathfinder lander employed an innovative air bag landing system, supplemented with aerobraking, parachute, and solid rocket landing thrusters. This prototype successfully tested the concept, and the two Mars Exploration Rover Mission landers employed similar landing systems. The Beagle 2 Mars lander also tried to use air bags for landing, but the landing was unsuccessful for reasons that are not entirely known.

Occupant protection

The U.S. Army has incorporated air bags in its UH-60A/L[22] Black Hawk and OH-58D Kiowa Warrior[23] helicopter fleets. The Cockpit Air Bag System (CABS) consists of forward and lateral air bags with an Electronic Crash Sensor Unit (ECSU).[24] The CABS system was conceived and developed by the U.S. Army Aviation Applied Technology Directorate, Fort Eustis, VA.[25] It is the first conventional air bag system for occupant injury prevention designed and developed specifically for helicopter applications.[26][27]

| |||||||||||||||||||||||||||||||||||||||||

See also

- Automobile

- Assen Jordanoff

- Safety engineering

Notes

- ↑ Audi, Airbag, Glossary. Retrieved August 13, 2008.

- ↑ NHTSA, Deactivation. Retrieved August 23, 2008.

- ↑ 3.0 3.1 Newsome Law Firm, Generation I Airbags / Legal Articles / Resources. Retrieved August 13, 2008.

- ↑ American Heritage, l The Rough Road to Airbags. Retrieved August 13, 2008.

- ↑ ENotes, How Products Are Made: Airbags. Retrieved August 13, 2008.

- ↑ 6.0 6.1 John Fenton, The Times.

- ↑ Image Shack, Airbag Deployment illustrations. Retrieved August 13, 2008.

- ↑ Image Shack, Buick Owners Manual Cover. Retrieved August 13, 2008.

- ↑ Byron Bloch, Advanced designs for side impact and rollover protection. Retrieved August 13, 2008.

- ↑ Euro NCAP, Frontal impact test description. Retrieved August 13, 2008.

- ↑ The Auto Channel, BMW Head Protection System Sets New Standard in Side-Impact Protection in Latest IIHS Crash Test. Retrieved August 13, 2008.

- ↑ Safer Car, NHTSA Side-Impact Airbags. Retrieved August 13, 2008.

- ↑ Audi, Airbag control unit. Retrieved August 13, 2008.

- ↑ Safer Car, Frontal Airbags. Retrieved August 13, 2008.

- ↑ Free Patents Online, Thermally stable nonazide automotive air bag propellants—Patent 6306232. Retrieved August 13, 2008.

- ↑ NHTSA, Deactivation. Retrieved August 23, 2008.

- ↑ NHTSA, Tests for Requirements to Improve Occupant Protection for Different Size Occupants, Belted and Unbelted. Retrieved August 13, 2008.

- ↑ NHTSA, Air Bag Contact Injuries. Retrieved August 23, 2008.

- ↑ D. Ulrich et al., Burn injuries caused by air bag deployment, NCBI PubMed. Retrieved August 23, 2008.

- ↑ Carin M. Olson, Peter Cummings, and Frederick P. Rivara, Association of First- and Second-Generation Air bags with Front Occupant Death in Car Crashes: A Matched Cohort Study, American Journal of Epidemiology 164 (2): 161-169. Retrieved August 13, 2008.

- ↑ Charles J. Kahane, Airbags—National Highway Traffic Safety Administration. Retrieved August 13, 2008.

- ↑ DefenseLink, Contracts. Retrieved August 13, 2008.

- ↑ FAS, FAS OH-58D article. Retrieved August 13, 2008.

- ↑ Armor Holdings, Armor Holdings CABS Fact Sheet. Retrieved August 13, 2008.

- ↑ Air University, Air Defense concept papers. Retrieved August 13, 2008.

- ↑ BNet, BNET News Release on AHS Annual Forum award. Retrieved August 13, 2008.

- ↑ Special Operations Technology, Tougher Choppers. Retrieved August 13, 2008.

ReferencesISBN links support NWE through referral fees

- Chan, Ching-Yao. 2000. Fundamentals of Crash Sensing in Automotive Air Bag Systems. Warrendale, PA: Society of Automotive Engineers. ISBN 0768004993.

- Kent, Richard W. 2003. Air Bag Development and Performance: New Perspectives from Industry, Government, and Academia. Warrendon, PA: Society of Automotive Engineers. ISBN 0768011191.

- Parker, Philip M. 2006. The 2007-2012 World Outlook for New Air Bag Assemblies and Related Parts for Motor Vehicles. San Diego, CA: ICON Group International, Inc. ISBN 0497328968.

External links

All links retrieved June 16, 2023.

- "How Airbags Work". Howstuffworks.

- The History of Airbags. About.com.

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.