Difference between revisions of "Spring (device)" - New World Encyclopedia

| Line 10: | Line 10: | ||

== Materials used for springs == | == Materials used for springs == | ||

| − | As noted above, various elastic materials can be used to make springs. Even fluids under pressure demonstrate spring-like | + | As noted above, various elastic materials can be used to make springs. Even fluids under pressure demonstrate spring-like properties. Most springs, however, are made of metal, particularly [[hardened steel]]. Small springs can be wound from pre-hardened stock, while larger ones are made from [[annealing (metallurgy)|annealed]] steel and hardened after fabrication. Some [[ferrous and non-ferrous metals|non-ferrous metals]] are also used, including [[phosphor bronze]] for parts requiring corrosion resistance, and [[beryllium copper]] for springs carrying electrical current (because of its low electrical resistance). |

==Types of springs== | ==Types of springs== | ||

| Line 18: | Line 18: | ||

The most common types of springs are: | The most common types of springs are: | ||

| − | *[[Coil spring]] or [[helix|helical]] spring | + | *[[Coil spring]] or [[helix|helical]] spring (a spring made by winding a wire around a cylinder) and the [[Cone (geometry)|conical]] spring. These are known as [[torsion spring]]s, because the wire itself is twisted when the spring is compressed or stretched. They, in turn, are of two types: |

**''Tension springs'' are designed to become longer under load. Their turns are normally touching in the unloaded position, and they have a hook, eye or some other means of attachment at each end. | **''Tension springs'' are designed to become longer under load. Their turns are normally touching in the unloaded position, and they have a hook, eye or some other means of attachment at each end. | ||

**''Compression springs'' are designed to become shorter when loaded. Their turns are not touching in the unloaded position, and they need no attachment points. A ''[[volute]]'' spring is a compression spring in the form of a cone so that under compaction the coils are not forced against each other, thus permitting longer travel. | **''Compression springs'' are designed to become shorter when loaded. Their turns are not touching in the unloaded position, and they need no attachment points. A ''[[volute]]'' spring is a compression spring in the form of a cone so that under compaction the coils are not forced against each other, thus permitting longer travel. | ||

| − | *[[Leaf spring]] - a flat springy sheet, used in vehicle [[suspension (vehicle)|suspension]]s | + | *[[Leaf spring]] - a flat springy sheet, used in vehicle [[suspension (vehicle)|suspension]]s, electrical [[switch]]es, and [[bow (weapon)|bow]]s. |

* [[V-spring]] - used in antique [[firearm]] mechanisms such as the [[wheellock]], [[flintlock]], and [[percussion cap]] locks. | * [[V-spring]] - used in antique [[firearm]] mechanisms such as the [[wheellock]], [[flintlock]], and [[percussion cap]] locks. | ||

| − | *[[Spiral spring]] or 'clock spring' - a spring of the type | + | *[[Spiral spring]] or 'clock spring' - a spring of the type used in [[clock]]s, [[galvanometer]]s, and places where electricity must be carried to partially rotating devices such as [[steering wheel]]s. |

*[[springboard|Cantilever spring]] - a spring which is fixed only at one end. | *[[springboard|Cantilever spring]] - a spring which is fixed only at one end. | ||

Other types include: | Other types include: | ||

| − | *[[Belleville washer]] or Belleville spring - a disc shaped spring commonly used to apply tension to a bolt (and also in the initiation mechanism of pressure-activated [[land mine|landmines]]). | + | *[[Belleville washer]] or Belleville spring - a disc-shaped spring commonly used to apply tension to a bolt (and also in the initiation mechanism of pressure-activated [[land mine|landmines]]). |

*Spring [[Washer (mechanical)|washer]] - used to apply a constant tensile force along the axis of a [[fastener]]. | *Spring [[Washer (mechanical)|washer]] - used to apply a constant tensile force along the axis of a [[fastener]]. | ||

| Line 55: | Line 55: | ||

===Simple harmonic motion=== | ===Simple harmonic motion=== | ||

| − | + | ||

| − | + | Given that [[force]] (''F'') is equal to [[mass]] (''m'') times [[acceleration]], ''a'', the force equation looks like: | |

::<math>F = - k x = m a. \,</math> | ::<math>F = - k x = m a. \,</math> | ||

| + | |||

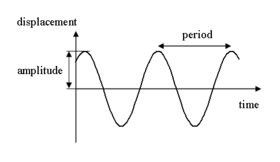

[[Image:Simple harmonic motion.png|thumb|right|280px|The displacement, ''x'', as a function of time. The amount of time that passes between peaks is called the [[period]].]] | [[Image:Simple harmonic motion.png|thumb|right|280px|The displacement, ''x'', as a function of time. The amount of time that passes between peaks is called the [[period]].]] | ||

| + | |||

But acceleration is just the second time [[derivative]] of x, so | But acceleration is just the second time [[derivative]] of x, so | ||

::<math> - k x = m \frac{d^2 x}{dt^2}. \,</math> | ::<math> - k x = m \frac{d^2 x}{dt^2}. \,</math> | ||

| Line 73: | Line 75: | ||

[[Hooke's law]] of [[theory of elasticity|elasticity]] states that the extension of an elastic rod (its distended length minus its relaxed length) is linearly proportional to its [[Tension (mechanics)|tension]], the [[force]] used to stretch it. Similarly, the contraction (negative extension) is proportional to the [[Physical compression|compression]] (negative tension). | [[Hooke's law]] of [[theory of elasticity|elasticity]] states that the extension of an elastic rod (its distended length minus its relaxed length) is linearly proportional to its [[Tension (mechanics)|tension]], the [[force]] used to stretch it. Similarly, the contraction (negative extension) is proportional to the [[Physical compression|compression]] (negative tension). | ||

| − | This law | + | This law is valid only approximately, and only when the deformation (extension or contraction) is small compared to the rod's overall length. For deformations beyond the [[Tensile strength|elastic limit]], atomic bonds get broken or rearranged, and a spring may snap, buckle, or permanently deform. Many materials have no clearly defined elastic limit, and Hooke's law cannot be meaningfully applied to these materials. |

| − | + | == Resistance to "creep" == | |

| − | Contrary to popular belief, springs do not appreciably "[[Creep (deformation)|creep]]" or get "tired" with age. Spring steel has a very high resistance to creep under normal loads. The sag observed in older [[ | + | Contrary to popular belief, springs do not appreciably "[[Creep (deformation)|creep]]" or get "tired" with age. Spring steel has a very high resistance to creep under normal loads. The sag observed in older [[automobile]]s is really due to the springs being occasionally compressed beyond their yield point, causing plastic deformation. This can happen when the vehicle hits a large bump or pothole, especially when heavily loaded. Most vehicles will accumulate a number of such impacts over their working life, leading to a lower ride height and eventual bottoming-out of the suspension. |

==Wikibooks modules== | ==Wikibooks modules== | ||

Revision as of 02:03, 15 September 2007

A spring is a flexible, elastic device used to store mechanical energy. When a force is applied to a spring, it expands or contracts to a certain extent, and when the force is released, the spring attempts to return to its earlier state.

Springs can be made of a variety of elastic materials, including fluids, but springs used in mechanical devices are generally made of metal. They also vary in shape; familiar shapes being helical, spiral, and flat.

Based on their behavior, springs are used to move objects, absorb vibrations, and control mechanical shock. For instance, they are useful in clocks, shock absorbers, motorized toys, automobile engine valves, and door-closing mechanisms.

Materials used for springs

As noted above, various elastic materials can be used to make springs. Even fluids under pressure demonstrate spring-like properties. Most springs, however, are made of metal, particularly hardened steel. Small springs can be wound from pre-hardened stock, while larger ones are made from annealed steel and hardened after fabrication. Some non-ferrous metals are also used, including phosphor bronze for parts requiring corrosion resistance, and beryllium copper for springs carrying electrical current (because of its low electrical resistance).

Types of springs

The most common types of springs are:

- Coil spring or helical spring (a spring made by winding a wire around a cylinder) and the conical spring. These are known as torsion springs, because the wire itself is twisted when the spring is compressed or stretched. They, in turn, are of two types:

- Tension springs are designed to become longer under load. Their turns are normally touching in the unloaded position, and they have a hook, eye or some other means of attachment at each end.

- Compression springs are designed to become shorter when loaded. Their turns are not touching in the unloaded position, and they need no attachment points. A volute spring is a compression spring in the form of a cone so that under compaction the coils are not forced against each other, thus permitting longer travel.

- Leaf spring - a flat springy sheet, used in vehicle suspensions, electrical switches, and bows.

- V-spring - used in antique firearm mechanisms such as the wheellock, flintlock, and percussion cap locks.

- Spiral spring or 'clock spring' - a spring of the type used in clocks, galvanometers, and places where electricity must be carried to partially rotating devices such as steering wheels.

- Cantilever spring - a spring which is fixed only at one end.

Other types include:

- Belleville washer or Belleville spring - a disc-shaped spring commonly used to apply tension to a bolt (and also in the initiation mechanism of pressure-activated landmines).

- Spring washer - used to apply a constant tensile force along the axis of a fastener.

- Torsion spring - any spring designed to be twisted rather than compressed or extended.

- Gas spring - a volume of gas that is compressed.

- Rubber band - a tension spring, where energy is stored by stretching the material.

Physics

Hooke's Law

When a spring is extended or compressed, it absorbs energy in the process. If the spring undergoes only slight stretching or compression, it obeys Hooke's law, which states that the force with which the spring pushes back is linearly proportional to the distance from its equilibrium length:

where

- x is the distance through which the spring has been elongated or compressed,

- F is the restoring force exerted by the spring, and

- k is the spring constant or force constant of the spring.

Simple harmonic motion

Given that force (F) is equal to mass (m) times acceleration, a, the force equation looks like:

But acceleration is just the second time derivative of x, so

Re-arranging results in a differential equation:

the solution of which is the sum of a sine and cosine:

The graph of this function is displayed in the image on the right.

Theory

In classical physics, a spring can be seen as a device that stores potential energy by straining the bonds between the atoms of an elastic material.

Hooke's law of elasticity states that the extension of an elastic rod (its distended length minus its relaxed length) is linearly proportional to its tension, the force used to stretch it. Similarly, the contraction (negative extension) is proportional to the compression (negative tension).

This law is valid only approximately, and only when the deformation (extension or contraction) is small compared to the rod's overall length. For deformations beyond the elastic limit, atomic bonds get broken or rearranged, and a spring may snap, buckle, or permanently deform. Many materials have no clearly defined elastic limit, and Hooke's law cannot be meaningfully applied to these materials.

Resistance to "creep"

Contrary to popular belief, springs do not appreciably "creep" or get "tired" with age. Spring steel has a very high resistance to creep under normal loads. The sag observed in older automobiles is really due to the springs being occasionally compressed beyond their yield point, causing plastic deformation. This can happen when the vehicle hits a large bump or pothole, especially when heavily loaded. Most vehicles will accumulate a number of such impacts over their working life, leading to a lower ride height and eventual bottoming-out of the suspension.

Wikibooks modules

ReferencesISBN links support NWE through referral fees

- Associated Spring Corporation. 1964. Handbook of Mechanical Spring Design. Bristol, CT: Associated Spring Corp. ASIN: B000TRJQEU.

- Brown, A. A. D. 1981. Mechanical Springs. Engineering Design Guides, 42. [S.l.]: Published for the Design Council, the British Standards Institution, and the Council of Engineering Institutions by Oxford University Press. ISBN 0198591810.

- Wahl, A. M. 1963. Mechanical Springs. New York: McGraw-Hill. OCLC 562873.

External links

- Left Hand Versus Right Hand Wound Springs Retrieved September 13, 2007.

- Spring Design & Spring Configuration Retrieved September 13, 2007.

- Spring Type Gallery Retrieved September 13, 2007.

- The Myth Of "Tired" Springs Retrieved September 13, 2007.

- Everything You Want To Know About Springs Retrieved September 13, 2007.

- Spring Terminology Retrieved September 13, 2007.

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.