Plow

- "Plough" and "Furrow" redirect here.

The plow (American spelling: plow; both pronounced /plaʊ/) is a tool used in farming for initial cultivation of soil in preparation for sowing seed or planting. It has been a basic instrument for most of recorded history, and represents one of the major advances in agriculture. The primary purpose of ploughing is to turn over the upper layer of the soil, bringing fresh nutrients to the surface, while burying weeds and the remains of previous crops, allowing them to break down. It also aerates the soil, and allows it to hold moisture better. In modern use, a ploughed field is typically left to dry out, and is then harrowed before planting.

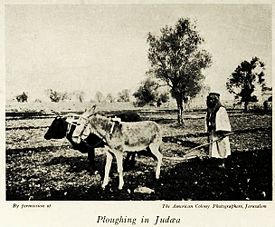

Plows were initially pulled by oxen, and later in many areas by horses. In industrialised countries, the first mechanical means of pulling a plough used steam-power (ploughing engines or steam tractors), but these were gradually superseded by internal-combustion-powered tractors. In the past two decades plough use has reduced in some areas (where soil damage and erosion are problems), in favor of shallower ploughing and other less invasive tillage techniques.

Ploughs are even used under the sea, for the laying of cables, as well as preparing the earth for side-scan sonar[citation needed] in a process used in oil exploration.

Etymology

In English, as in other Germanic languages, the plough was traditionally known by other names, e.g. Old English sulh, Old High German medela or huohili, and Old Norse arðr.

The current word plough also comes from Germanic, but it appears relatively late (it is absent from Gothic), and is thought to be a loanword from one of the north Italic languages. In these it had different meanings: in Raetic plaumorati (Pliny), and in Latin plaustrum "wagon, cart", plóstrum, plóstellum "cart", and plóxenum, plóximum "cart box".[1][2]

The word first appears in Germanic as Lombardic plóvum. This term was borrowed into Balto-Slavic languages, such as Old Church Slavonic plugъ and Lithuanian plúgas. Ultimately, the word is thought to derive from an ancestral PIE *blōkó, related to Armenian pelem "to dig" and Welsh bwlch "gap, notch".[3][4]

History of the plough

Hoeing

When agriculture was first developed, simple hand-held digging sticks or hoes would have been used in highly fertile areas, such as the banks of the Nile where the annual flood rejuvenates the soil, to create furrows wherein seeds could be sown. In order to regularly grow crops in less fertile areas, the soil must be turned to bring nutrients to the surface.

Scratch plough

The domestication of oxen in Mesopotamia and by its contemporary Indus valley civilization, perhaps as early as the 6th millennium B.C.E., provided mankind with the pulling power necessary to develop the plough. The very earliest plough was the simple scratch-plough, or ard, which consists of a frame holding a vertical wooden stick that was dragged through the topsoil (still used in many parts of the world). It breaks up a strip of land directly along the ploughed path, which can then be planted. Because this form of plough leaves a strip of undisturbed earth between the rows, fields are often cross-ploughed at right angles, and this tends to lead to squarish fields[5] In the archeology of northern Europe, such squarish fields are referred to as "Celtic fields".

Crooked ploughs

The Greeks apparently introduced the next major advance in plough design; the crooked plough, which angled the cutting surface forward, leading to the name. The cutting surface was often faced with bronze or (later) iron. Metal was expensive, so in times of war it was melted down or forged to make weapons – or the reverse in more peaceful times. This is presumably the origin of the term "beat your swords to ploughshares".

Mouldboard plough

A major advance in plough design was the mouldboard plough (American spelling: moldboard plow), which aided the cutting blade. The coulter, knife or skeith cuts vertically into the ground just ahead of the share (or frog) a wedge-shaped surface to the front and bottom of the mouldboard with the landside of the frame supporting the below-ground components. The upper parts of the frame carries (from the front) the coupling for the motive power (horses), the coulter and the landside frame. Depending on the size of the implement, and the number of furrows it is designed to plough at one time, there is a wheel or wheels positioned to support the frame. In the case of a single-furrow plough there is only one wheel at the front and handles at the rear for the ploughman to steer and manoeuvre it.

When dragged through a field the coulter cuts down into the soil and the share cuts horizontally from the previous furrow to the vertical cut. This releases a rectangular strip of sod that is then lifted by the share and carried by the mouldboard up and over, so that the strip of sod (slice of the topsoil) that is being cut lifts and rolls over as the plough moves forward, dropping back to the ground upside down into the furrow and onto the turned soil from the previous run down the field. Each gap in the ground where the soil has been lifted and moved across (usually to the right) is called a furrow. The sod that has been lifted from it rests at about a 45 degree angle in the next-door furrow and lies up the back of the sod from the previous run.

In this way, a series of ploughing runs down a field (paddock) leaves a row of sods that lie partly in the furrows and partly on the ground lifted earlier. Visually, across the rows, there is the land (unploughed part) on the left, a furrow (half the width of the removed strip of soil) and the removed strip almost upside-down lying on about half of the previous strip of inverted soil, and so on across the field. Each layer of soil and the gutter it came from forms the classic furrow.

The mouldboard plough greatly reduced the amount of time needed to prepare a field, and as a consequence, allowed a farmer to work a larger area of land. In addition, the resulting pattern of low (under the mouldboard) and high (beside it) ridges in the soil forms water channels, allowing the soil to drain. In areas where snow buildup is an issue, this allows the soil to be planted earlier as the snow runoff is drained away more quickly.

Parts of a mouldboard plough: There are 5 major parts of a mouldboard plough

- Mouldboard

- Share

- Landside

- Frog

- Tailpiece

A runner extending from behind the share to the rear of the plough controls the direction of the plough, because it is held against the bottom land-side corner of the new furrow being formed. The holding force is the weight of the sod, as it is raised and rotated, on the curved surface of the mouldboard. Because of this runner, the mouldboard plough is harder to turn around than the scratch plough, and its introduction brought about a change in the shape of fields—from mostly square fields into longer rectangular "strips" (hence the introduction of the furlong).

An advance on the basic design was the ploughshare, a replaceable horizontal cutting surface mounted on the tip of the mouldboard. Introduced by the Celts in Britain around 4000 B.C.E. (without the replaceable feature), early mouldboards were basically wedges that sat inside the cut formed by the coulter, turning over the soil to the side. The ploughshare spread the cut horizontally below the surface, so when the mouldboard lifted it, a wider area of soil was turned over.

Heavy ploughs

In the basic mouldboard plough the depth of the cut is adjusted by lifting against the runner in the furrow, which limited the weight of the plough to what the ploughman could easily lift. This limited the construction to a small amount of wood (although metal edges were possible). These ploughs were fairly fragile, and were unsuitable for breaking up the heavier soils of northern Europe. The introduction of wheels to replace the runner allowed the weight of the plough to increase, and in turn allowed the use of a much larger mouldboard faced in metal. These heavy ploughs led to greater food production and eventually a significant population increase around 600 C.E.

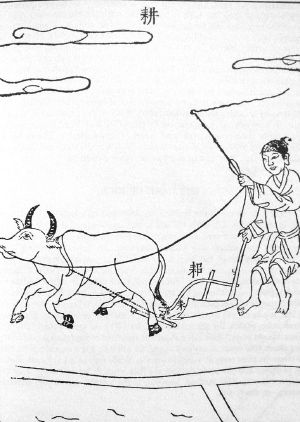

Heavy Iron ploughs were invented in Han Dynasty China around 100 B.C.E.[citation needed] Despite a number of innovations, the Romans never achieved the heavy wheeled mouldboard plough. The first indisputable appearance after the Roman period is from 643, in a northern Italian document[6]. Old words in connected with the heavy plough and its use appear in Slavic, suggesting possible early use in this region[7]. The general adoption of the mouldboard plough in Europe appears to have accompanied the adoption of the three-field system in the later eighth and early ninth centuries, leading to an improvement of the agricultural productivity per unit of land in northern Europe.[8]

Research by the French historian Marc Bloch in medieval French agricultural history showed the existence of names for two different ploughs, "the araire was wheel-less and had to be dragged across the fields, while the charrue was mounted on wheels".[9]

Improved designs

The basic plough with coulter, ploughshare and mouldboard remained in use for a millennium. Major changes in design did not become common until the Age of Enlightenment, when there was rapid progress in design. The Dutch are credited with the introduction of newer shapes for the mouldboard in the 1600s, although these shapes were known earlier in China and may have been discovered by the Dutch while there.[10]

Joseph Foljambe in Rotherham, England, in 1730 used these new shapes as the basis for the Rotherham plough, which also covered the mouldboard with iron.[11] Unlike the heavy plough, the Rotherham (or Rotherham swing) plough consisted entirely of the coulter, mouldboard and handles. It was much lighter than conventional designs and became very popular in England. It may have been the first plough to be widely built in factories.

James Small further improved the design. Using mathematical methods he experimented with various designs until he arrived at a shape cast from a single piece of iron, the Scots plough. This was again improved on by Jethro Wood, a blacksmith of Scipio, New York, who made a three-part Scots Plough that allowed a broken piece to be replaced. In 1837 John Deere introduced the first steel plough; it was much stronger than iron designs that it was able to work the soil in areas of the US that had earlier been considered unsuitable for farming. Improvements on this followed developments in metallurgy; steel coulters and shares with softer iron mouldboards to prevent breakage, the chilled plough which is an early example of surface-hardened steel[12], and eventually the face of the mouldboard grew strong enough to dispense with the coulter.

Single-sided ploughing

The first mouldboard ploughs could only turn the soil over in one direction (conventionally always to the right), as dictated by the shape of the mouldboard, and so the field had to be ploughed in long strips, or lands. The plough was usually worked clockwise around each land, ploughing the long sides and being dragged across the short sides without ploughing. The length of the strip was limited by the distance oxen (or later horses) could comfortably work without a rest, and their width by the distance the plough could conveniently be dragged. These distances determined the traditional size of the strips: a furlong, (or "furrow's length", 220 yards (200 m)) by a chain (22 yards (20 m)) – an area of one acre (about 0.4 hectares); this is the origin of the acre. The one-sided action gradually moved soil from the sides to the centre line of the strip. If the strip was in the same place each year, the soil built up into a ridge, creating the ridge and furrow topography still seen in some ancient fields.

Turnwrest plough

The turnwrest plough allows ploughing to be done to either side. The mouldboard is removable, turning to the right for one furrow, then being moved to the other side of the plough to turn to the left (the coulter and ploughshare are fixed). In this way adjacent furrows can be ploughed in opposite directions, allowing ploughing to proceed continuously along the field and thus avoiding the ridge and furrow topography.

Reversible plough

The reversible plough has two mouldboard ploughs mounted back-to-back, one turning to the right, the other to the left. While one is working the land, the other is carried upside-down in the air. At the end of each row, the paired ploughs are turned over, so the other can be used. This returns along the next furrow, again working the field in a consistent direction.

Riding and multiple-furrow ploughs

Early steel ploughs, like those for thousands of years prior, were walking ploughs, directed by the ploughman holding onto handles on either side of the plough. The steel ploughs were so much easier to draw through the soil that the constant adjustments of the blade to react to roots or clods was no longer necessary, as the plough could easily cut through them. Consequently it was not long after that the first riding ploughs appeared. On these, wheels kept the plough at an adjustable level above the ground, while the ploughman sat on a seat where he would have earlier walked. Direction was now controlled mostly through the draught team, with levers allowing fine adjustments. This led very quickly to riding ploughs with multiple mouldboards, dramatically increasing ploughing performance.

A single draught horse can normally pull a single-furrow plough in clean light soil, but in heavier soils two horses are needed, one walking on the land and one in the furrow. For ploughs with two or more furrows more than two horses are needed and, usually, one or more horses have to walk on the loose ploughed sod—and that makes hard going for them, and the horse treads the newly ploughed land down. It is usual to rest such horses every half hour for about ten minutes.

Heavy volcanic loam soils, such as are found in New Zealand, require the use of four heavy draught horses to pull a double-furrow plough. Where paddocks are more square than long-rectangular it is more economical to have horses four wide in harness than two-by-two ahead, thus one horse is always on the ploughed land (the sod). The limits of strength and endurance of horses made greater than two-furrow ploughs uneconomic to use on one farm.[citation needed]

Amish farmers tend to use a team of about seven horses or mules when spring ploughing and as Amish farmers often help each other plough, teams are sometimes changed at noon. Using this method about 10 acres can be ploughed per day in light soils and about 2 acres (8,100 m²) in heavy soils.[citation needed]

Steam ploughing

The advent of the mobile steam engine allowed steam power to be applied to ploughing from about 1850. In Europe, soil conditions were too soft to support the weight of the heavy traction engines. Instead, counterbalanced, wheeled ploughs, known as balance ploughs, were drawn by cables across the fields by pairs of ploughing engines which worked along opposite field edges. The balance plough had two sets of ploughs facing each other, arranged so when one was in the ground, the other set was lifted into the air. When pulled in one direction the trailing ploughs were lowered onto the ground by the tension on the cable. When the plough reached the edge of the field, the opposite cable was pulled by the other engine, and the plough tilted (balanced), the other set of shares were put into the ground, and the plough worked back across the field.

One set of ploughs was right-handed, and the other left-handed, allowing continuous ploughing along the field, as with the turnwrest and reversible ploughs. The man credited with the invention of the ploughing engine and the associated balance plough, in the mid nineteenth century, was John Fowler, an English agricultural engineer and inventor.

In America the firm soil of the Plains allowed direct pulling with steam tractors, such as the big Case, Reeves or Sawyer Massey breaking engines. Gang ploughs of up to fourteen bottoms were used. Often these big ploughs were used in regiments of engines, so that in a single field there might be ten steam tractors each drawing a plough. In this way hundreds of acres could be turned over in a day. Only steam engines had the power to draw the big units. When internal combustion engines appeared, they had neither the strength nor the ruggedness compared to the big steam tractors. Only by reducing the number of shares could the work be completed.

Stump-jump plough

The Stump-jump plough was an Australian invention of the 1870s, designed to cope with the breaking up of new farming land, that contains many tree stumps and rocks that would be very expensive to remove. The plough uses a moveable weight to hold the ploughshare in position. When a tree stump or other obstruction such as a rock is encountered, the ploughshare is thrown upwards, clear of the obstacle, to avoid breaking the plough's harness or linkage; ploughing can be continued when the weight is returned to the earth after the obstacle is passed.

A simpler system, developed later, uses a concave disc (or a pair of them) set at a large angle to the direction of progress, that uses the concave shape to hold the disc into the soil – unless something hard strikes the circumference of the disk, causing it to roll up and over the obstruction. As the arrangement is dragged forward, the sharp edge of the disc cuts the soil, and the concave surface of the rotating disc lifts and throws the soil to the side. It doesn't make as good a job as the mouldboard plough (but this is not considered a disadvantage, because it helps fight the wind erosion), but it does lift and break up the soil.

Modern ploughs

Modern ploughs are usually multiple reversible ploughs, mounted on a tractor via a three-point linkage. These commonly have between two and as many as seven mouldboards – and semi-mounted ploughs (the lifting of which is supplemented by a wheel about half-way along their length) can have as many as eighteen mouldboards. The hydraulic system of the tractor is used to lift and reverse the implement, as well as to adjust furrow width and depth. The ploughman still has to set the draughting linkage from the tractor so that the plough is carried at the proper angle in the soil. This angle and depth can be controlled automatically by modern tractors.

Specialist ploughs

Chisel plough

The chisel plough is a common tool to get deep tillage with limited soil disruption. The main function of this plough is to loosen and aerate the soils while leaving crop residue at the top of the soil. This plough can be used to reduce the effects of compaction and to help break up ploughpan and hardpan. Unlike many other ploughs the chisel will not invert or turn the soil. This characteristic has made it a useful addition to no-till and limited-tillage farming practices which attempt to maximise the erosion-prevention benefits of keeping organic matter and farming residues present on the soil surface through the year. Because of these attributes, the use of a chisel plough is considered by some to be more sustainable than other types of plough, such as the mouldboard plough.

The chisel plough is typically set to run up to a depth of eight to twelve inches (200 to 300 mm). However some models may run much deeper. Each of the individual ploughs, or shanks, are typically set from nine inches (229 mm) to twelve inches (305 mm) apart. Such a plough can encounter significant soil drag, consequently a tractor of sufficient power and good traction is required. When planning to plough with a chisel plough it is important to bear in mind that 10 to 15 horsepower (7 to 11 kW) per shank will be required.

Ridging plough

A ridging plough is used for crops, such as potatoes, which are grown buried in ridges of soil. A ridging plough has two mouldboards facing away from each other, cutting a deep furrow on each pass, with high ridges either side. The same plough may be used to split the ridges to harvest the crop.

Mole plough

The mole plough or subsoiler allows underdrainage to be installed without trenches, or it breaks up deep impermeable soil layers which impede drainage. It is a very deep plough, with a torpedo-shaped or wedge-shaped tip, and a narrow blade connecting this to the body. When dragged through the ground, it leaves a channel deep under the ground, and this acts as a drain. Modern mole ploughs may also bury a flexible perforated plastic drain pipe as they go, making a more permanent drain – or they may be used to lay pipes for water supply or other purposes.

Use of the mouldboard plough

In modern use, the mouldboard plough was used for three reasons:-

- Foremost was the control of weeds. In this function, mouldboard ploughing is very successful, a farmer can control weed growth with far fewer herbicides by using this technique than is otherwise possible with any other method, aside from hand weeding, which is labour-intensive and not practical for large operations.

- To break up the soil for planting.

- To warm the soil for planting.

Only the first reason for mouldboard ploughing really paid off. Most plants require little soil agitation to germinate, so breaking up soil is unnecessary beyond what a planting implement accomplishes on its own. Soil warming is also unnecessary beyond two or three inches (76 mm) below the surface, therefore bringing black fresh soil which heats more quickly and more deeply after the final frost of the year is unneeded.

Problems with mouldboard ploughing

Mouldboard ploughing has become increasingly recognised as a highly destructive farming practice with the possibility of rapidly depleting soil resources. In the short term, however, it can be successful, hence the reason it was practised for such a long time. A field that is mouldboarded once will generally have an extraordinary one time yield as the larvae of pests and seed from weeds are buried too deeply to survive. After the first harvest, however, continued mouldboarding will diminish yields greatly.

The diminishing returns of mouldboard ploughing can be attributed to a number of side effects of the practice:-

- Foremost is the formation of hardpan, or the calcification of the sub layer of soil. In some areas, hardpan could once be found so thick it could not be broken up with a pickaxe. The only effective means of removing hardpan is using a "ripper", or chisel plough, which is pulled through the hardpan by an extremely powerful and costly tractor. Obviously, this layer eventually becomes impenetrable to the roots of plants and restricts growth and yields. This layer also becomes impenetrable to water, leading to flooding and the drowning of crops.

- Deep (> 15-20 cm) mouldboard ploughing rapidly depletes the organic matter content of soil and promotes erosion; these two problems go hand in hand. As soil is brought to the surface, the root structure of the previous harvest is broken up, and the natural adhesion of soil particles is also lost; though loose soil appears good for plant germination (and it is), this loose soil without cohesion is highly susceptible to erosion, multiplying the rate of erosion by several factors compared to a non-mouldboarded plot. This increased rate of erosion will not only outpace the rate of soil genesis but also the replacement rate for organics in the soil, thus depleting the soil more rapidly than normal.

- Deep (> 15-20 cm) mouldboard ploughing leads to increased soil compaction and loss of pore space within the soil. Soil is a bit like a bucket full of balls filled with sand. Each ball represents a cohesive particle of soil, and when stacked the balls leave a great deal of air space, required for healthy root growth and proper drainage. Mouldboarding so disturbs the soil that it breaks these balls and releases their contents. When this happens, the much smaller particles that are within the larger particles are released and pore space diminishes, leading to hard compacted soil that floods easily and restricts root growth.

Soil erosion

One negative effect of ploughing is to dramatically increase the rate of soil erosion, both by wind and water, where soil is moved elsewhere on land or deposited in bodies of water, such as the oceans. Ploughing is thought to be a contributing factor to the Dust Bowl in the US in the 1930s. Alternatives to ploughing, such as the no till method, have the potential to limit damage while still allowing farming.

Plough parts

- Frame

- Frog

- Share (also called a plowshare or ploughshare)

- Mouldboard (or moldboard)

- Runner

- Landside

- Shin

- Trashboard

- Handles

- Hitch

- Knife, skeith or coulter

On modern ploughs and some older ploughs, the mouldboard is separate from the share and runner, allowing these parts to be replaced without replacing the mouldboard. Abrasion eventually destroys all parts of a plough that contact the soil.

See also

- Snowplow

- Ridge and furrow

Notes

- ↑ C.T. Onions, ed., Oxford Dictionary of English Etymology, s.v. "plough" (Oxford: Clarendon Press, 1996).

- ↑ Webster's Encyclopedic Unabridged Dictionary of the English Language, s.v. "plow" (NY: Gramercy Books, 1996).

- ↑ Vladimir Orel, A Handbook of Germanic Etymology, s.v. "plôZuz" (Leiden, Netherlands: Brill, 2003).

- ↑ Collins-Spurrell Welsh Dictionary, Collins, 1960. ISBN 0 00 433402 7: "Bwlch"

- ↑ Lynn White, Jr., Medieval Technology and Social Change (Oxford: University Press, 1962), p. 42.

- ↑ White, Medieval Technology, p. 50

- ↑ White, Medieval Technology, pp. 49f

- ↑ White, Medieval Technology, pp. 69-78

- ↑ Marc Bloch, French Rural History, translated by Janet Sondheimer (Berkeley: University Press, 1966), p.50

- ↑ "The Genius of China", Robert Temple, p.16–20

- ↑ A Brief History of The Plough

- ↑ John Deere (1804–1886)

ReferencesISBN links support NWE through referral fees

- The Genius of China", Robert Temple, Prion Books Limited, ISBN 1853752924

External links

- The Rotherham Plough – the first commercially successful iron plough

- History of the steel plough – as developed by John Deere in the US

- Breast Ploughs and other antique hand farm tools

- Various types of plough: photos

| ||||

|---|---|---|---|---|

|

Cutting tools - Adze | Axe | Bolt cutters | Ceramic tile cutter | Chainsaw | Machete | Kukri | Saw | Knife | Broach | Endmill | Reamer | Drill bit | Tool bit | Countersink | Front teeth | Milling cutter | Razor blade |Scalpel | Scissors | Blade | Fingernail | Switchblade | Water jet cutter

Garden tools - Cultivator | Garden fork | Hedge trimmer | Hoe | Hori hori | Lawnmower | Lawn aerator | Leaf blower | Leaf sweeper | Loppers | Mattock | McLeod | Mini-tractor | Pitchfork | Plow | Pruning shears | Pulaski | Rake (tool) | Secateurs | Spade | Sprinkler | String trimmer | Trimmer

Hand tools - Brace | Chisel | Hammer | Screwdriver | Handsaw | Pliers | Torque wrench | Clamp | Level | Sponge

Power tools - Band saw | Belt sander | Chainsaw | Circular saw | Concrete saw | Crusher | Diamond blade | Disc sander | Drill | Impact wrench | Grinder | Heat gun | Jointer | Jigsaw | Lathe | Radial arm saw | Random orbital sander | Rotary tool | Sander | Table saw | Thickness planer | Wood router

See also - Antique tools | Diamond tools

| ||||

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.