Difference between revisions of "Bakelite" - New World Encyclopedia

(imported latest version of article from Wikipedia) |

(added credit and category tags, deleted foreign language links) |

||

| Line 56: | Line 56: | ||

*[http://juliensart.be/bakeliet Virtual Bakelite Museum of Ghent 1907-2007] | *[http://juliensart.be/bakeliet Virtual Bakelite Museum of Ghent 1907-2007] | ||

| − | [[Category: | + | [[Category:Physical sciences]] |

| − | [[Category: | + | [[Category:Chemistry]] |

| − | [[Category: | + | [[Category:Chemical engineering]] |

| − | [[Category: | + | [[Category:Plastics]] |

| − | + | {{credit|228642644}} | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Revision as of 18:12, 30 July 2008

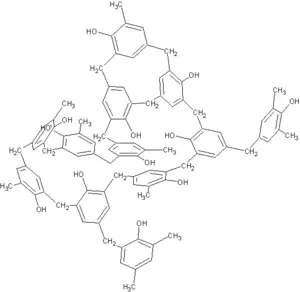

Template:Cleanup Bakelite (pronounced /ˈbеɪkɨlaɪt/) is a material based on the thermosetting phenol formaldehyde resin, polyoxybenzylmethylenglycolanhydride developed in 1907–1909 by Belgian Dr. Leo Baekeland. Formed by the reaction under heat and pressure of phenol (a toxic, colourless crystalline solid) and formaldehyde (a simple organic compound), generally with a wood flour filler, it was the first plastic made from synthetic components. It was used for its electrically nonconductive and heat-resistant properties in radio and telephone casings and electrical insulators, and was also used in such diverse products as kitchenware, jewelry, pipe stems, and children's toys. In 1993 Bakelite was designated an ACS National Historical Chemical Landmark in recognition of its significance as the world's first synthetic plastic.[1]

The retro appeal of old Bakelite products and labor intensive manufacturing has made them quite collectible in recent years.

Bakelite AG (a German company) claims to own the trademark in the following countries: Argentina, Australia, Austria, Bangladesh, Benelux, China, Cuba, Egypt, France, Germany, Great Britain, Greece, India, Ireland, Israel, Italy, Liechtenstein, Republic of Macedonia, Malaysia, Morocco, New Zealand, Norway, Pakistan, Switzerland, Singapore, Slovakia, Spain, Sri Lanka, South Africa, Taiwan, Thailand, Czech Republic, Tunisia, Hungary.[2]

History

Bakelite Corp. was formed in 1922 from the consolidation of three companies. General Bakelite Co., Condensite Corp. and Redmanol Chemical Products Company, an early plastics manufacturer formed in 1913 by Chemist L.H.Baekeland. The American Catalin Corporation acquired the Bakelite formulas in 1927 and currently manufactures Bakelite cast resins.

Bakelite Limited was formed in 1926 from the amalgamation of three suppliers of phenol formaldehyde materials: the Damard Lacquer Company Limited of Birmingham; Mouldensite Limited of Darley Dale and Redmanol Chemical Products Company of London. Around 1928 a new factory opened in Tyseley, Birmingham, England. (The building was demolished in 1998.) The company was acquired by the Union Carbide and Carbon Corporation in 1939.

Properties

Phenolics are seldom used in general consumer products today due to the cost and complexity of production and their brittle nature. An exception to the overall decline is the use in small precision-shaped components where their specific properties are required, such as moulded disc brake cylinders, saucepan handles, electrical plugs and switches and electrical iron parts. Today, Bakelite is manufactured and produced in the form of sheets, rods and tubes for hundreds of industrial applications in the electronics, power generation and aerospace industries, and under a variety of commercial brand names.

Phenolic sheet is a hard, dense material made by applying heat and pressure to layers of paper or glass cloth impregnated with synthetic resin. These layers of laminations are usually of cellulose paper, cotton fabrics, synthetic yarn fabrics, glass fabrics or unwoven fabrics. When heat and pressure are applied to the layers, a chemical reaction (polymerization) transforms the layers into a high-pressure thermosetting industrial laminated plastic. When rubbed, original Bakelite has a telltale odor.

Bakelite Phenolic is produced in dozens of commercial grades and with various additives to meet diverse mechanical, electrical and thermal requirements. Some common types include:

- PAPER REINFORCED PHENOLIC NEMA XX per MIL-I-24768 PBG Normal electrical applications, moderate mechanical strength, continuous operating temperature of 250°F.

- CANVAS REINFORCED PHENOLIC NEMA C per MIL-I-24768 TYPE FBM NEMA CE per MIL-I-24768 TYPE FBG Good mechanical and impact strength with continuous operating temperature of 250°F.

- LINEN REINFORCED PHENOLIC NEMA L per MIL-I-24768 TYPE FBI NEMA LE per MIL-I-24768 TYPE FEI Good mechanical and electrical strength. Recommended for intricate high strength parts. Continuous operating temperature 250°F.

- NYLON REINFORCED PHENOLIC NEMA N-1 per MIL-I-24768 TYPE NPG Superior electrical properties under humid conditions, fungus resistant, continuous operating temperature of 160°F.

Patents

- U.S. Patent 0942809 (PDF)—Condensation product and method of making same

(After following the patent link, click on the "Images" button to view the patent. You will need a TIFF (.tif) viewer to view the patent.)

Applications and usage

Although not extensively used as an industrial manufacturing material any more, in the past Bakelite was used in a myriad of applications, such as saxophone mouthpieces, cameras, solid-body electric guitars, rotary-dial telephones, early machine guns, and appliance casings. It was at one point considered for the manufacture of coins, due to a shortage of traditional manufacturing material.[citation needed]Template:Where`

See also

- Ansco panda — children's Bakelite box camera

- Bayko — A construction set toy in which most of the parts were made of Bakelite

- Catalin

- Novotext

- Phenol formaldehyde resin

- Phenolic resin

ReferencesISBN links support NWE through referral fees

- ↑ New Products

- ↑ Our reference - Protection of brands. Bakelite AG (June 18, 2007).

External links

- Bakelite: JJ Zimmermann's Virtual Bakelite Museum in Basel, Switzerland: one of the world's largest private collections can be visited in a special exhibition http://www.15squaredevergennes.com in Paris until August 2, 2008

- Bakelite: The Material of a Thousand Uses

- Virtual Bakelite Museum of Ghent 1907-2007

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.