Difference between revisions of "Kiln" - New World Encyclopedia

m (→Kiln History) |

m (→Kiln History) |

||

| Line 6: | Line 6: | ||

[[Image:Apollonia-79-lime-kiln.jpg|thumb|right|240px|Ancient Apollonia lime kiln in Israel]] | [[Image:Apollonia-79-lime-kiln.jpg|thumb|right|240px|Ancient Apollonia lime kiln in Israel]] | ||

| − | Kilns are thermally insulated chambers, or [[oven]]s, in which a controlled temperature regime is produced. They are used to harden, burn or dry materials. The firing of kilns requires a specific fuel, air or oxygen quality and flow to "feed" the fire, and a specific time for the firing. Specific uses include firing [[ceramic]] materials, heating wood to the point of [[pyrolysis]] to produce [[charcoal]], annealing, fusing, casting and deforming glass, wood drying for firewood including drying green [[lumber]] for immediate use, [[cremation]], drying malted barley or hops for [[brewing]], and tobacco leaves. | + | Kilns are thermally insulated chambers, or [[oven]]s, in which a controlled temperature regime is produced. They are used to harden, burn or dry materials. The firing of kilns requires a specific fuel, air or oxygen quality and flow to "feed" the fire, and a specific time for the firing. Specific uses include firing [[ceramic]] materials, heating wood to the point of [[pyrolysis]] to produce [[charcoal]], annealing, fusing, casting and deforming glass, wood drying for firewood including drying green [[lumber]] for immediate use, [[cremation]], creating lime, drying malted barley or hops for [[brewing]], and tobacco leaves. Types of fuel include: wood, electricity, oil, natural gas, coal, or propane. |

== Intermittent and Continuous Kilns == | == Intermittent and Continuous Kilns == | ||

| − | + | Kilns either allow the materials to come into contact with the flames, as in Lime kilns, and those in which the heat source is underneath or surrounding the enclosure, for brick, glass and pottery kilns, and the drying of organic materials. | |

| − | + | Currently, in the broadest terms, there are two styles of kilns, both sharing the same basic characteristics of being an insulated box with controlled inner temperature and atmosphere. | |

| − | ''Continuous''—Sometimes called ''tunnel'' kilns, these are long structures in which only the central portion is directly heated. From the cool entrance, ware is slowly transported through the kiln on a conveyor, and its temperature is increased steadily as it approaches the central, hottest part of the kiln for a specific period of time. From there, its transportation continues and the temperature is reduced until it exits the kiln at near room temperature. A specialty type of kiln, common in tableware and tile manufacture, is the ''Roller-hearth Kiln'', in which ware placed on bats (flat, high-fired clay | + | ''Intermittent''—The ''ware'' is loaded into the kiln, which is then sealed, and the internal temperature increased according to a schedule. There is an increase of heat to a specific temperature, a holding time, and then a decrease of temperature. This is a stationary firing system, nothing moves in or out of the kiln. After the firing process is complete, both the kiln and ware are cooled and then opened and emptied.<ref>The exception to this is Western Raku firing which uses the intermittent-type box kiln but the ware is taken out while still red hot and placed in a burning receptacle in order for the carbon to dye the piece.</ref> |

| + | |||

| + | ''Continuous''—Sometimes called ''tunnel'' kilns, these are long structures in which only the central portion is directly heated. From the cool entrance, ware is slowly transported through the kiln on a conveyor, and its temperature is increased steadily as it approaches the central, hottest part of the kiln for a specific period of time. From there, its transportation continues and the temperature is reduced until it exits the kiln on the other side at near room temperature. A specialty type of kiln, common in commercial tableware and tile manufacture, is the ''Roller-hearth Kiln'', in which ware placed on bats (flat, high-fired clay slabs)is carried through the kiln on rollers. | ||

==Kiln History== | ==Kiln History== | ||

| − | Kiln technology is very old. The development of the kiln from a simple earthen trench filled with pots and fuel ([[Pit fired pottery|pit firing]]) to modern methods occurred in several simple stages. One improvement was to build a firing chamber around pots with baffles and a stoking hole, which allowed heat to be conserved and used more efficiently. The use of a [[chimney]] stack improved the air flow or ''draw'' of the kiln, thus burning the fuel more completely | + | Kiln technology is very old. The development of the kiln from a simple earthen trench filled with pots and fuel ([[Pit fired pottery|pit firing]]) to modern methods occurred in several simple stages. One improvement was to build a firing chamber around pots with baffles <ref>A usually static device that regulates the flow of air. By controlling the air or oxygen flow, the temperature can be controlled.</ref>and a stoking hole<ref>The place where wood or other fuel is placed into the burn chamber.</ref>, which allowed heat to be conserved and used more efficiently. The use of a [[chimney]] stack improved the air flow or ''draw'' of the kiln, thus burning the fuel more completely. |

| − | |||

| − | |||

[[image:Anagama kiln.svg|thumb|250px|right|Anagama kiln<br /> | [[image:Anagama kiln.svg|thumb|250px|right|Anagama kiln<br /> | ||

| Line 28: | Line 28: | ||

6 Chimney.<br /> | 6 Chimney.<br /> | ||

7 Refractory arch]] | 7 Refractory arch]] | ||

| + | Early examples of kilns found in the [[United Kingdom]] include those for the making of roof-tiles during the [[Roman Britain|Roman]] occupation. These kilns were built up the side of a slope, such that a fire could be lit at the bottom and the heat would rise up into the kiln (similar to the Anagama kiln) for greater consistent heat control. | ||

| − | |||

[[Image:Anagama kiln being built.jpg|thumb|right|250px|Anagama kiln being built into the side of a hill to allow the upward natural flow of heat]] | [[Image:Anagama kiln being built.jpg|thumb|right|250px|Anagama kiln being built into the side of a hill to allow the upward natural flow of heat]] | ||

| + | '''Anagama kiln''' - the Asian [[Anagama kiln]] has been used greatly since medieval times and is the oldest style of kiln in [[Japan]]. This single-chamber kiln, was introduced from Korea in the fifth century; it is favored by potters who prefer natural ash glazes. This kiln usually consists of one long firing chamber, pierced with smaller stacking ports on one side, with a firebox at one end and a flue at the other end. The firing time can vary from one day to several weeks. Traditional Anagama kilns were also built on a slope to allow for a better draft. [[Noborigama]] (multi-chamber climbing) kilns were invented around the seventeenth century in Japan, which allowed for greater production during one firing, ten to twenty times more pottery could be fired at one time. Also, the glaze firing became more consistent with this style of kiln. Many potters favor the wood-burning Anagama kiln, for it produces fly ash, which settles on the pieces, melts, and creates a natural ash glaze that cannot be achieved with any other type of firing. The interior of the kiln "moves" and changes as the water and organic particles burn off producing varied results, none ever an exact copy of another. | ||

In modern times there has been a revival of Anagama kilns in Japan, led by Furutani Michio and Yasuhisa Kouyama. Also, a style of kiln known as ''Kazegama'', <ref>[http://www.kazegamas.com/kazegama.htm "Wind kiln"]. '''www.kazegamas.com''. Retrieved August 23, 2007.</ref>was developed by Steve Davis of the USA in 1997 as an alternative to traditional wood firing practices such as those achieved in an Anagama kiln. | In modern times there has been a revival of Anagama kilns in Japan, led by Furutani Michio and Yasuhisa Kouyama. Also, a style of kiln known as ''Kazegama'', <ref>[http://www.kazegamas.com/kazegama.htm "Wind kiln"]. '''www.kazegamas.com''. Retrieved August 23, 2007.</ref>was developed by Steve Davis of the USA in 1997 as an alternative to traditional wood firing practices such as those achieved in an Anagama kiln. | ||

| + | |||

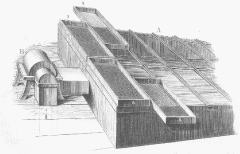

| + | ==Drying of tobacco and hops== | ||

| + | [[Image:Oast_House_in_Tudeley_Kent.jpg|thumb|230px|Oast House in Tudeley, Kent, now in residential use]] | ||

| + | Before modern technology simplified the drying of organic materials, they were usually dried in a barn or house with multiple, perforated floors allowing the heat, from a small kiln fueled by wood or charcoal, to slowly rise through all levels over a period of time. And the heat escaped through a cowl in the roof which turned with the wind. Tobacco was gathered by hand after it dried, packaged and sent for cigar, cigarette and chewing tobacco production. | ||

| + | |||

| + | The freshly picked hops from the fields were raked in to dry and then raked out to cool before being bagged up and sent to the brewery. England used [[oast houses]] - usually a round house with several floors to dry hops for brewing - in the sixteenth to twentieth centuries when square houses replaced the round ones. | ||

==Types of Kilns== | ==Types of Kilns== | ||

| + | There are a variety of types of kilns used over time as technology developed. Their use was specific for the type of ware produced. | ||

| + | |||

* '''Bottle kiln''' - a type of intermittent kiln, usually coal-fired, formerly used in the firing of pottery; such a kiln was surrounded by a tall brick hovel or cone, typically bottle shaped. | * '''Bottle kiln''' - a type of intermittent kiln, usually coal-fired, formerly used in the firing of pottery; such a kiln was surrounded by a tall brick hovel or cone, typically bottle shaped. | ||

| Line 49: | Line 58: | ||

== Ceramic or Pottery kilns == | == Ceramic or Pottery kilns == | ||

| − | Kilns are an essential part of the manufacture of [[ceramics]], which requires firing at high temperatures. During this process, chemical and physical reactions occur which cause the clay material to be permanently altered. For [[pottery]], clay materials are shaped, dried, and then fired in a kiln. The final look and condition is determined by the chemical composition of the clay body, the preparation process, the temperature at which it is fired, and the glazes that may be used. | + | Kilns are an essential part of the manufacture of [[ceramics]], which requires firing at high temperatures. During this process, chemical and physical reactions occur which cause the clay material to be permanently altered. For [[pottery]], clay materials are shaped, dried, and then fired in a kiln. The final look and condition is determined by the chemical composition of the clay body, the preparation process, the temperature and length of the "hold" time at which it is fired, and the glazes that may be used. |

[[Image:Stacked kiln.jpg|thumb|left|250px|A stacked kiln ready for firing glazed pottery]] | [[Image:Stacked kiln.jpg|thumb|left|250px|A stacked kiln ready for firing glazed pottery]] | ||

| − | [[Clay]] consists of fine-grained particles that are relatively weak and porous. Part of the firing process includes [[sintering]] where the clay becomes a coherent mass. The firing process heats the clay until the particles partially melt and flow together, creating a strong, single mass composed of pores and crystalline material <ref>Primarily [[silicon]] and [[aluminum]] oxides.</ref>and the glassy glaze. | + | [[Clay]] consists of fine-grained particles that are relatively weak and porous. Part of the firing process includes [[sintering]] where the clay becomes a coherent mass. The firing process heats the clay until the particles partially melt and flow together, creating a strong, single mass composed of pores and crystalline material<ref>Primarily [[silicon]] and [[aluminum]] oxides.</ref>and the glassy glaze. |

Through firing, the pores are reduced in size as water and organic materials burn off, causing the clay to shrink and become more dense resulting in a hard, and strong yet brittle piece. The higher the kiln temperature the denser the piece becomes. | Through firing, the pores are reduced in size as water and organic materials burn off, causing the clay to shrink and become more dense resulting in a hard, and strong yet brittle piece. The higher the kiln temperature the denser the piece becomes. | ||

| − | [[Earthenware]] is fired at 1800°F to 2100°F. It is lighter and easier to break and porous, thus needing to be glazed in order to seal it against moisture and the glaze is fused to the surface of the clay - which when hit - allows | + | [[Earthenware]] is fired at 1800°F to 2100°F. It is lighter and easier to break and porous, thus needing to be glazed in order to seal it against moisture, and the glaze is fused to the surface of the clay - which when hit - allows chipped edges. It is not frost proof. Yet it is cheaper to produce and the glaze colors are often brighter and can be more exciting. Stoneware is much denser, heavier and the glaze and clay join together on a cellular level. When you hit a stoneware piece the glaze doesn't break off but a piece of the pot with glaze connected can break off. It is impervious to liquids, freezing and is fired at 2000°F to 2300°F. It takes a longer time to fire increasing the cost. It is often referred to as "man-made rock." |

Prior to established kilns, pottery was fired in outdoor bonfires, open pits, or ditches. This style of firing was unreliable at best. Consistent results were seldom seen and the weather had a strong influence on the results of the firing. Since the temperature in these processes was unlikely to exceed 700°F, these wares are considered low-fired [[earthenware]] with a short life and were easily broken. Many pieces broke during the firing and it was impossible to keep a consistent temperature throughout the pit. | Prior to established kilns, pottery was fired in outdoor bonfires, open pits, or ditches. This style of firing was unreliable at best. Consistent results were seldom seen and the weather had a strong influence on the results of the firing. Since the temperature in these processes was unlikely to exceed 700°F, these wares are considered low-fired [[earthenware]] with a short life and were easily broken. Many pieces broke during the firing and it was impossible to keep a consistent temperature throughout the pit. | ||

| − | [[Image:Raku-pottery-kiln.jpg|thumb|right|200px|Western Raku kiln]] Mastering the art of kiln firing is a daunting task, and no two firings are ever exactly the same. Controlling the kiln - even by a master - is a challenge. There are just too many variables to consider: how much air/oxygen, wood, or other fuels to use. Timing of the fuel addition, control of temperatures, stoking in a wood fire, and how to stack the pieces, and where to place the pieces. Six tea cups placed in different areas of a kiln can turn out with totally different colors using the same glaze and clay because the interior of the kiln has 'hot' and 'cold' spots and some areas have faster moving air and different organic burn off. And then there is the possibility of another nearby pot affecting the glaze of your favorite piece. Sometimes a fine "mist" of another pot can be transfered to its neighbor. The potter controls about 85 percent of the process but the other factors are beyond his or her control. It is like the weather, always changing. Each time the kiln is finally opened to reveal the results of a firing, each potter holds his or her breath as if in prayer, to see the results which are often up to the whim of the 'kama no kami' or kiln god." <ref>[http://www.e-yakimono.net/guide/html/raku-yaki.html Raku kiln firing]. ''www.e-yakimono.net''. Retrieved August 29, 2007.</ref> | + | [[Image:Raku-pottery-kiln.jpg|thumb|right|200px|Western Raku kiln]] Mastering the art of kiln firing is a daunting task, and no two firings are ever exactly the same. Controlling the kiln - even by a master - is a challenge. There are just too many variables to consider: how much air/oxygen, wood, or other fuels to use. Timing of the fuel addition, control of temperatures, stoking in a wood fire, and how to stack the pieces, and where to place the pieces. Six tea cups placed in different areas of a kiln can turn out with totally different colors and surface texture using the same glaze and clay because the interior of the kiln has 'hot' and 'cold' spots and some areas have faster moving air and different organic burn off. And then there is the possibility of another nearby pot affecting the glaze of your favorite piece. Sometimes a fine "mist" off of another pot can be transfered to its neighbor. The potter controls about 85 percent of the process but the other factors are beyond his or her control. It is like the weather, always changing. Each time the kiln is finally opened to reveal the results of a firing, each potter holds his or her breath as if in prayer, to see the results which are often up to the whim of the 'kama no kami' or kiln god." <ref>[http://www.e-yakimono.net/guide/html/raku-yaki.html Raku kiln firing]. ''www.e-yakimono.net''. Retrieved August 29, 2007.</ref> |

==Glass kiln== | ==Glass kiln== | ||

[[Image:Cloisonnebeads.jpg|thumb|200px|Cloisonné beads]] | [[Image:Cloisonnebeads.jpg|thumb|200px|Cloisonné beads]] | ||

| − | Kilns are also used to heat glass to to the point that it can | + | Kilns are also used to heat glass to to the point that it can be molded into specific shapes, fuse glass onto another material, or melted for artistic use—a process called ''[[annealing]]''. |

| − | |||

| − | |||

| − | + | [[Cloisonné]] is enameled metal containing fine gold or silver lines into which powered colored glass called ''[[frit]]'' is poured. Spaces for the ''frit'' are made by wire glued to the surface of the metal and then melted in a kiln along with the ''frit'' that fills in the areas as it melts. Other uses for decorative glass, such as stained glass windows, jewelry, pottery decoration, and other uses can all involve melting glass in a small kiln. | |

| − | |||

| − | + | == Wood-drying kiln technology == | |

| + | Wood drying kilns shorten the time it takes for wood to be usable for burning as firewood, or used as building material. A variety of wood drying kiln technologies exist today. The types are conventional, dehumidification, solar, vacuum and radio frequency. | ||

| − | + | '''Conventional''' is either a side-loaded intermittent kiln filled by forklift, or a tram system like a tunnel kiln. Heat is typically introduced via steam running through fin/tube heat exchangers controlled by on/off pneumatic valves. | |

| − | + | In general, cool dry air is introduced at one end of the kiln while warm moist air is expelled at the other, and the introduction of humidity via either steam spray or cold water misting systems to keep the relative humidity inside the kiln from dropping too low. Fan directions are typically reversed periodically to ensure even drying of larger kiln charges. | |

Most softwood lumber kilns operate below 240°F. Hardwood lumber kiln drying schedules typically keep the dry bulb temperature below 180°F. Easy to dry species might not exceed 140°F. | Most softwood lumber kilns operate below 240°F. Hardwood lumber kiln drying schedules typically keep the dry bulb temperature below 180°F. Easy to dry species might not exceed 140°F. | ||

| − | + | '''[[Dehumidification]]''' kilns are very similar to conventional kilns in basic construction. Drying times are usually comparable. Heat is primarily supplied by an integral dehumidification unit which removes the humidity which dries out the kiln. | |

| − | + | '''[[Solar kiln]]'''s are conventional kilns, typically built by hobbyists to keep initial investment costs low. Heat is provided via solar radiation, while internal air circulation is typically passive. | |

| − | + | '''[[Vacuum]]''' kilns include the use of reduced atmospheric pressure to attempt to speed up the drying process, like a pressure cooker. Hot water [[platten vacuum kiln]]s use aluminum heating plates to circulate the hot water and operate at significantly reduced absolute pressure. When the kiln reaches full atmospheric pressure, the air in the chamber is then heated, and finally the vacuum is pulled. SSV kilns are significantly more popular in Europe where the locally harvested wood is easier to dry versus species found in North America. | |

| − | + | '''[[RF/V]]''' (radio frequency + vacuum) kilns use microwave radiation to heat the kiln, and typically have the highest operating cost due to the heat being provided by electricity rather than local fossil fuel or waste wood sources. | |

==Economic and Environmental Concerns for Wood Drying== | ==Economic and Environmental Concerns for Wood Drying== | ||

| Line 92: | Line 99: | ||

The total (harmful) air emissions produced by wood kilns, including their heat source, can be significant. Typically, the higher the temperature the kiln operates at, the larger amount of emissions are produced (per pound of water removed). This is especially true in the drying of thin veneers and high-temp drying of softwoods. | The total (harmful) air emissions produced by wood kilns, including their heat source, can be significant. Typically, the higher the temperature the kiln operates at, the larger amount of emissions are produced (per pound of water removed). This is especially true in the drying of thin veneers and high-temp drying of softwoods. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Cremation Kilns== | ==Cremation Kilns== | ||

Revision as of 01:57, 5 September 2007

Kilns are thermally insulated chambers, or ovens, in which a controlled temperature regime is produced. They are used to harden, burn or dry materials. The firing of kilns requires a specific fuel, air or oxygen quality and flow to "feed" the fire, and a specific time for the firing. Specific uses include firing ceramic materials, heating wood to the point of pyrolysis to produce charcoal, annealing, fusing, casting and deforming glass, wood drying for firewood including drying green lumber for immediate use, cremation, creating lime, drying malted barley or hops for brewing, and tobacco leaves. Types of fuel include: wood, electricity, oil, natural gas, coal, or propane.

Intermittent and Continuous Kilns

Kilns either allow the materials to come into contact with the flames, as in Lime kilns, and those in which the heat source is underneath or surrounding the enclosure, for brick, glass and pottery kilns, and the drying of organic materials.

Currently, in the broadest terms, there are two styles of kilns, both sharing the same basic characteristics of being an insulated box with controlled inner temperature and atmosphere.

Intermittent—The ware is loaded into the kiln, which is then sealed, and the internal temperature increased according to a schedule. There is an increase of heat to a specific temperature, a holding time, and then a decrease of temperature. This is a stationary firing system, nothing moves in or out of the kiln. After the firing process is complete, both the kiln and ware are cooled and then opened and emptied.[1]

Continuous—Sometimes called tunnel kilns, these are long structures in which only the central portion is directly heated. From the cool entrance, ware is slowly transported through the kiln on a conveyor, and its temperature is increased steadily as it approaches the central, hottest part of the kiln for a specific period of time. From there, its transportation continues and the temperature is reduced until it exits the kiln on the other side at near room temperature. A specialty type of kiln, common in commercial tableware and tile manufacture, is the Roller-hearth Kiln, in which ware placed on bats (flat, high-fired clay slabs)is carried through the kiln on rollers.

Kiln History

Kiln technology is very old. The development of the kiln from a simple earthen trench filled with pots and fuel (pit firing) to modern methods occurred in several simple stages. One improvement was to build a firing chamber around pots with baffles [2]and a stoking hole[3], which allowed heat to be conserved and used more efficiently. The use of a chimney stack improved the air flow or draw of the kiln, thus burning the fuel more completely.

Early examples of kilns found in the United Kingdom include those for the making of roof-tiles during the Roman occupation. These kilns were built up the side of a slope, such that a fire could be lit at the bottom and the heat would rise up into the kiln (similar to the Anagama kiln) for greater consistent heat control.

Anagama kiln - the Asian Anagama kiln has been used greatly since medieval times and is the oldest style of kiln in Japan. This single-chamber kiln, was introduced from Korea in the fifth century; it is favored by potters who prefer natural ash glazes. This kiln usually consists of one long firing chamber, pierced with smaller stacking ports on one side, with a firebox at one end and a flue at the other end. The firing time can vary from one day to several weeks. Traditional Anagama kilns were also built on a slope to allow for a better draft. Noborigama (multi-chamber climbing) kilns were invented around the seventeenth century in Japan, which allowed for greater production during one firing, ten to twenty times more pottery could be fired at one time. Also, the glaze firing became more consistent with this style of kiln. Many potters favor the wood-burning Anagama kiln, for it produces fly ash, which settles on the pieces, melts, and creates a natural ash glaze that cannot be achieved with any other type of firing. The interior of the kiln "moves" and changes as the water and organic particles burn off producing varied results, none ever an exact copy of another.

In modern times there has been a revival of Anagama kilns in Japan, led by Furutani Michio and Yasuhisa Kouyama. Also, a style of kiln known as Kazegama, [4]was developed by Steve Davis of the USA in 1997 as an alternative to traditional wood firing practices such as those achieved in an Anagama kiln.

Drying of tobacco and hops

Before modern technology simplified the drying of organic materials, they were usually dried in a barn or house with multiple, perforated floors allowing the heat, from a small kiln fueled by wood or charcoal, to slowly rise through all levels over a period of time. And the heat escaped through a cowl in the roof which turned with the wind. Tobacco was gathered by hand after it dried, packaged and sent for cigar, cigarette and chewing tobacco production.

The freshly picked hops from the fields were raked in to dry and then raked out to cool before being bagged up and sent to the brewery. England used oast houses - usually a round house with several floors to dry hops for brewing - in the sixteenth to twentieth centuries when square houses replaced the round ones.

Types of Kilns

There are a variety of types of kilns used over time as technology developed. Their use was specific for the type of ware produced.

- Bottle kiln - a type of intermittent kiln, usually coal-fired, formerly used in the firing of pottery; such a kiln was surrounded by a tall brick hovel or cone, typically bottle shaped.

- Top-hat Kiln - an intermittent kiln of a type sometimes used in the firing of pottery. The ware is set on a refractory hearth, or slab, over which a box-shaped cover is then lowered.

- Electric kilns - kilns operated by electricity were developed in the 20th century, primarily for smaller scale use in schools, universities, and hobby centers. As these electrical appliances improved in dependability they became a valuable tool for artists as well. The atmosphere in most designs of electric kiln is rich in oxygen, as there is no open flame to consume oxygen molecules, however reducing (of oxygen to produce specific glaze results) conditions can be created with appropriate gas input.

- Car kiln - The bottom of the kiln is not attached to the sides and is set upon a rail-mounted cart. This enables the floor to be loaded and unloaded without the inconvenience of working inside of the kiln.

- Modern kilns - with the advent of the industrial age, kilns were designed to utilize electricity and more refined fuels, including natural gas and propane. The majority of large, industrial pottery kilns now use natural gas, as it is generally clean, efficient and easy to control. Modern kilns can be fitted with computerized controls, allowing for refined adjustments during the firing cycle. A user may choose to control the rate of temperature climb or ramp, hold or soak the temperature at any given point, or control the rate of cooling. Both electric and gas kilns are common for smaller scale production in industry and craft, handmade and sculptural work.

- Microwave Assisted Firing - this technique combines microwave energy with more conventional energy sources such as radiant gas or electric heating in order to process ceramic materials to the required high temperatures. Microwave-assisted firing offers significant economic benefits.

Ceramic or Pottery kilns

Kilns are an essential part of the manufacture of ceramics, which requires firing at high temperatures. During this process, chemical and physical reactions occur which cause the clay material to be permanently altered. For pottery, clay materials are shaped, dried, and then fired in a kiln. The final look and condition is determined by the chemical composition of the clay body, the preparation process, the temperature and length of the "hold" time at which it is fired, and the glazes that may be used.

Clay consists of fine-grained particles that are relatively weak and porous. Part of the firing process includes sintering where the clay becomes a coherent mass. The firing process heats the clay until the particles partially melt and flow together, creating a strong, single mass composed of pores and crystalline material[5]and the glassy glaze.

Through firing, the pores are reduced in size as water and organic materials burn off, causing the clay to shrink and become more dense resulting in a hard, and strong yet brittle piece. The higher the kiln temperature the denser the piece becomes.

Earthenware is fired at 1800°F to 2100°F. It is lighter and easier to break and porous, thus needing to be glazed in order to seal it against moisture, and the glaze is fused to the surface of the clay - which when hit - allows chipped edges. It is not frost proof. Yet it is cheaper to produce and the glaze colors are often brighter and can be more exciting. Stoneware is much denser, heavier and the glaze and clay join together on a cellular level. When you hit a stoneware piece the glaze doesn't break off but a piece of the pot with glaze connected can break off. It is impervious to liquids, freezing and is fired at 2000°F to 2300°F. It takes a longer time to fire increasing the cost. It is often referred to as "man-made rock."

Prior to established kilns, pottery was fired in outdoor bonfires, open pits, or ditches. This style of firing was unreliable at best. Consistent results were seldom seen and the weather had a strong influence on the results of the firing. Since the temperature in these processes was unlikely to exceed 700°F, these wares are considered low-fired earthenware with a short life and were easily broken. Many pieces broke during the firing and it was impossible to keep a consistent temperature throughout the pit.

Mastering the art of kiln firing is a daunting task, and no two firings are ever exactly the same. Controlling the kiln - even by a master - is a challenge. There are just too many variables to consider: how much air/oxygen, wood, or other fuels to use. Timing of the fuel addition, control of temperatures, stoking in a wood fire, and how to stack the pieces, and where to place the pieces. Six tea cups placed in different areas of a kiln can turn out with totally different colors and surface texture using the same glaze and clay because the interior of the kiln has 'hot' and 'cold' spots and some areas have faster moving air and different organic burn off. And then there is the possibility of another nearby pot affecting the glaze of your favorite piece. Sometimes a fine "mist" off of another pot can be transfered to its neighbor. The potter controls about 85 percent of the process but the other factors are beyond his or her control. It is like the weather, always changing. Each time the kiln is finally opened to reveal the results of a firing, each potter holds his or her breath as if in prayer, to see the results which are often up to the whim of the 'kama no kami' or kiln god." [6]

Glass kiln

Kilns are also used to heat glass to to the point that it can be molded into specific shapes, fuse glass onto another material, or melted for artistic use—a process called annealing.

Cloisonné is enameled metal containing fine gold or silver lines into which powered colored glass called frit is poured. Spaces for the frit are made by wire glued to the surface of the metal and then melted in a kiln along with the frit that fills in the areas as it melts. Other uses for decorative glass, such as stained glass windows, jewelry, pottery decoration, and other uses can all involve melting glass in a small kiln.

Wood-drying kiln technology

Wood drying kilns shorten the time it takes for wood to be usable for burning as firewood, or used as building material. A variety of wood drying kiln technologies exist today. The types are conventional, dehumidification, solar, vacuum and radio frequency.

Conventional is either a side-loaded intermittent kiln filled by forklift, or a tram system like a tunnel kiln. Heat is typically introduced via steam running through fin/tube heat exchangers controlled by on/off pneumatic valves.

In general, cool dry air is introduced at one end of the kiln while warm moist air is expelled at the other, and the introduction of humidity via either steam spray or cold water misting systems to keep the relative humidity inside the kiln from dropping too low. Fan directions are typically reversed periodically to ensure even drying of larger kiln charges.

Most softwood lumber kilns operate below 240°F. Hardwood lumber kiln drying schedules typically keep the dry bulb temperature below 180°F. Easy to dry species might not exceed 140°F.

Dehumidification kilns are very similar to conventional kilns in basic construction. Drying times are usually comparable. Heat is primarily supplied by an integral dehumidification unit which removes the humidity which dries out the kiln.

Solar kilns are conventional kilns, typically built by hobbyists to keep initial investment costs low. Heat is provided via solar radiation, while internal air circulation is typically passive.

Vacuum kilns include the use of reduced atmospheric pressure to attempt to speed up the drying process, like a pressure cooker. Hot water platten vacuum kilns use aluminum heating plates to circulate the hot water and operate at significantly reduced absolute pressure. When the kiln reaches full atmospheric pressure, the air in the chamber is then heated, and finally the vacuum is pulled. SSV kilns are significantly more popular in Europe where the locally harvested wood is easier to dry versus species found in North America.

RF/V (radio frequency + vacuum) kilns use microwave radiation to heat the kiln, and typically have the highest operating cost due to the heat being provided by electricity rather than local fossil fuel or waste wood sources.

Economic and Environmental Concerns for Wood Drying

Valid economic studies of different wood drying technologies are based on the total energy, capital, insurance/risk, environmental impacts, labor, maintenance, and product degrade costs for the task of removing water from the wood fiber. The true costs of the drying system can only be determined when comparing the total plant costs and risks with and without drying.

The total (harmful) air emissions produced by wood kilns, including their heat source, can be significant. Typically, the higher the temperature the kiln operates at, the larger amount of emissions are produced (per pound of water removed). This is especially true in the drying of thin veneers and high-temp drying of softwoods.

Cremation Kilns

The place where the cremation of a body takes place is called a crematorium. The crematorium consists of one or more ovens or furnaces and facilities for handling of the ashes. A cremation furnace (crematory) is a large furnace capable of reaching high temperatures up to approximately 1600-1800 °F (870-980 °C) with special modifications to ensure the efficient disintegration of the corpse. One of these modifications is the aiming of the flames at the corpse's torso, where a majority of the corpse's mass rests.

The crematorium may be part of chapel or a funeral home, or it may be part of an independent facility, coroner's office or a service offered by a cemetery.

The furnaces use a number of different fuel sources, such as natural or propane gas. Modern cremation furnaces include control systems that monitor the conditions inside the furnace while a cremation is taking place. The operator can make adjustments to provide for more efficient burning, as well as ensuring that minimal environmental pollution occurs. [7]

Notes

- ↑ The exception to this is Western Raku firing which uses the intermittent-type box kiln but the ware is taken out while still red hot and placed in a burning receptacle in order for the carbon to dye the piece.

- ↑ A usually static device that regulates the flow of air. By controlling the air or oxygen flow, the temperature can be controlled.

- ↑ The place where wood or other fuel is placed into the burn chamber.

- ↑ "Wind kiln". 'www.kazegamas.com. Retrieved August 23, 2007.

- ↑ Primarily silicon and aluminum oxides.

- ↑ Raku kiln firing. www.e-yakimono.net. Retrieved August 29, 2007.

- ↑ Cremation. www.encyclopediaproject.net. Retrieved August 23, 2007.

See also

ReferencesISBN links support NWE through referral fees

- Chavarria, Joaquim. The Big Book of Ceramics: A Guide to the History, Materials, Equipment and Techniques of Hand-Building, Throwing, Molding, Kiln-Firing and Glazing Pottery and Other Ceramic Objects, Watson-Guptill, 1994. ISBN 978-0823005086

- Hamer, Frank and Janet. The Potter's Dictionary of Materials and Techniques. A & C Black Publishers, Ltd., 1991. ISBN 0-8122-3112-0.

- King, Alan G. Ceramic Technology and Processing, Noyes Publishing, 2002. ISBN 978-0815514435

- Norton, F.H. Elements of Ceramics, 2nd ed., 1974. Addison-Wesley, ISBN 978-0201053067

- Reed, James S. Introduction to the Principles of Ceramic Processing, Wiley-Interscience, 1988. ISBN 978-0471845546

- Richerson, David W. Modern Ceramic Engineering: Properties, Processing, and Use in Design, 3rd ed., 2005. ISBN 978-1574446937

- Terpstra, R.A., Paul Pex, and Andre de Vreies. Ceramic Processing, Springer, 1995. ISBN 978-0412598302

External links

- Woodfirer Association. yiwa.org. Retrieved March 20, 2007.

- Drying Hardwoods. cfquesnel.com. Retrieved March 20, 2007.

- History of bottle ovens (kilns), from Gladstone Pottery Museum, Stoke-on-Trent, UK. www.stoke.gov.uk. Retrieved March 20, 2007.

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.