Potter's wheel

The potter's wheel is a machine used in the shaping of round ceramic wares. Very occasionally it is also known as a "potter's lathe", however this is different machine used for a shaping process, 'turning,' which is similar to shape metal and wood pieces. The wheel may also be used during the process of trimming excess clay from dried wares and for applying incised decoration or rings of color.

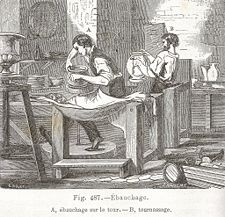

The techniques of jiggering and jolleying can be seen to be an extension of the Potters wheel: in jiggering, a shaped tool is slowly brought down onto a plastic (semi-dried) clay body that sits atop a rotating plaster mold. The jigger tool shapes one face as it molds the other. The term is specific to shaping of flatware, plates, and a similar technique, jolleying, refers to the production of holloware, cups or bowls (having a symmetrical, hollow center.

History

Many early ceramics were hand-built using a simple coiling technique in which the clay body was rolled into long coils that were then pinched and beaten together to form the body of a vessel. The vessel or the artist had to turn around the piece in order to wind the coils around the top of the piece, increasing in height at every complete turn.

In the coiling method of construction, all of the energy required to form the piece is supplied directly by the hands of the potter. This changed with the introduction of the fast-wheel. The wheel was kicked or turned with a stick and the heavy stone wheel continued to turn from its own weight. Unlike hand-building, in wheel-throwing the bulk of the energy used does not come directly from the hands of the potter but from the turning wheel. The introduction of the fast-wheel brought benefits in the form of speed, symmetrical shape and a job that might have taken hours, or even days, to complete was reduced to one that could be done in minutes.

Early ceramics built by coiling were often placed on mats or large leaves to allow them to be worked more conveniently. This arrangement allowed the potter to turn the vessel rather than walk around it to add coils to the clay body and it has been proposed that the earliest forms of the potter's wheel were developed as an extension to this procedure. The earliest versions of the wheel were probably turned slowly by hand or by foot while coiling a pot, but later developments allowed energy in the momentum of a flywheel to be used to speed up the process of throwing.

It is not known when the potter's wheel first came into use, but dates between about 6,000 B.C.E. to about 2,400 B.C.E. have been suggested. Many modern scholars suggest that it was first developed in Mesopotamia, although Egypt and China have also been claimed as possible places of origin. A stone potter's wheel found at the Mesopotamian city of Ur in modern-day Iraq has been dated to about 3,000 B.C.E., but fragments of wheel-thrown pottery of an even earlier date have been recovered in the same area. By the time of the early civilizations of the Bronze Age the use of the potter's wheel had become widespread.

In the Iron Age the potter's wheel in common use had a turning platform about a meter above the floor, connected by a long axle to a heavy flywheel at ground level. This arrangement allowed the potter to keep the turning-wheel rotating by kicking the flywheel with the foot, leaving both hands free for manipulating the vessel under construction.

Use of the potter's wheel became widespread throughout the Old World, but was unknown in the Pre-Columbian New World, where pottery was hand-made by methods that included coiling and beating.

The use of the motor-driven wheel has become common in modern times, particularly with craft potters and educational institutions, although human-powered ones are still in use and are much preferred by some potters.

Techniques of throwing

There are many techniques in use for throwing pots, although a typical procedure is:

1. Put a round, moist ball of clay body down onto the bat with water or small amount of clay smoothed over area to hold it, (attached to the wheel), less commonly known as a "batterboard"

2. Center the clay body on the wheel by applying pressure with a wet hand on the side and the other hand on the top. An alternative to this is to 'pull' the clay body up and down until it is centered

3. Find the center of the clay by moving a thumb across the clay until no more friction is felt as it turns

4. Push thumbs in the center of clay body; Stop at about 1/4 inch from the base

5. Widen the inside of the clay body

6. Pull up sides by crossing wet thumbs with two fingers on each side of the wall and slowly, slowly pulling up

7. Shape (push in or pull out)

8. Round the lip. Use a sponge or a piece of leather/chamois

9. Cut pot from bat by sliding a toggle, or cheese wire underneath the base of the pot to separate it from the bat

10. Dry until leatherhard

11. Trim base using carving tool attaching a griffin grip bat to the wheel or by securing the pot with other clay to hold it down

By using the Coil and Throw technique, it may be possible to throw larger pots, commonly up to 4 feet high. This requires more clay body, and generally greater skill:

1. Follow steps 1-7 in previous list

2. A blowlamp can be used to dry/firm the base. This allows larger coils to be added without fear of the pot collapsing

3. Add coils to the lip as the wheel is turning

4. Smooth coil to join with pot

5. Repeat step 4 as needed

6. Smooth lip with a chamois or by hand

7. Cut from bat with wire

8. Allow to get leatherhard

9. With great care, reverse pot on the wheel, secure and trim foot (base)

The potter's wheel in literature

In Ancient Egyptian mythology, the god Chnum was said to have formed the first humans on a potter's wheel.

The way in which clay body is shaped on a potter's wheel seems, even today, to have a magical quality to it; the clay body has the appearance of being a living thing that is being created or shaped by the potter. The potter and clay have long served as a metaphor for creation, and for the relationship of God to humankind:

- But now, O Lord, thou art our father; we are the clay, and thou our potter; and we all are the work of thy hand.

- —Isaiah 64:8

The "Rubaiyat of Omar Khayyam" makes sustained use of this metaphor. In FitzGerald's translation, a number of quatrains are collected into a Book of Pots, in which the pots engage in theological speculation:

And, strange to tell, among that Earthen Lot

Some could articulate, while others not:

And suddenly one more impatient cried—

“Who is the Potter, pray, and who the Pot?”

Another said—“Why, ne'er a peevish Boy,

“Would break the Bowl from which he drank in Joy;

“Shall He that made the vessel in pure Love

“And Fancy, in an after Rage destroy?”

None answer'd this; but after Silence spake

A Vessel of a more ungainly Make:

“They sneer at me for leaning all awry;

“What! did the Hand then of the Potter shake?”

Crankshaft

Ancient potters often used a stick to rotate the wheel, or an apprentice or servant would use the stick to turn the wheel.

The simplest way to spin the potter's wheel by foot is to sweep the foot from one side to the other against the spinning hub causing it to turn in one direction. From an ergonomic standpoint, this is rather awkward as only one leg is used in this process, much like driving a car using only the right foot, causing an imbalance in the muscles of the body. Yet the rhythm of the wheel turning on the kick wheel is an integral part of the balance and throwing of the pot, many weekend potters still use the traditional kick wheel for throwing clay for its link to early potters.

Another solution which was invented at an unknown time was to have a crankshaft with a lever, that converts up and down motion into rotary motion. Sewing machines such as those pioneered by the Singer Corporation have manual models operated by this method.

Types of potters wheels

Until the wheel was discovered, ancient potters had to deal with simple turning of the pot placed in their lap or on a plate or on the ground. Later, some wheels were used with a stick to push the pottery work area around. Finally, a kick wheel was devised where the foot could kick around the base wheel while the wheel head turned on a rotating shaft.

Modern potters tend to use the electric style of wheel as it gives consistent turning with little effort. Most wheels have several speeds at which to work, usually the foot presses down on an "accelerator" or foot plate to control the speed of the wheel head. Electric wheels tend to be smaller than kick wheels without the big concrete kick wheel below and the seat placed over it.

Electric wheels need only a small stool or other place to sit to work on the wheel. Additional parts may be added, such as a shelf for tools, water, sponges and so on. Different heads may be added to some of the electric wheels, making it easy to just add a new head and continue throwing while the previous pot dries on the last head. For wheels without interchangeable heads, a small bat may be attached to the wheel head with bolts or just several balls of clay.

The contemporary kick wheel is still a favorite for some potters who shun the electric wheel's commercialization and somewhat noisy electric motors. The kick wheel allows the potter to feel more of the rhythm of creation of a pot and the silence of the kick wheel allows a more "zen" sense of consciousness for the potter.

See also

ReferencesISBN links support NWE through referral fees

- Barnett, William & John Hoopes (eds.). (1995). The Emergence of Pottery. Washington: Smithsonian Institution Press. ISBN 1560985178

- Birks, Tony. The Complete Potter's Companion. Bulfinch Press Book: Little, Brown and Co., 1993. ISBN 0821224956

- Childe, V. G. (1951). Man Makes Himself. London: Watts & Co.

- Hamer, Frank and Janet Hamer. (1991). The Potter's Dictionary of Materials and Techniques, 3rd ed. London: A & C Black Publishers. ISBN 0812231120

- Hluch, Kevin. The Art of Contemporary American Pottery. Krause Pub., 2001. ISBN 0873419065

- Hopper, Robin. Advanced throwing on the potters wheel extended and altered forms, DVD video ©1995. OCLC: 57188895

- Kirkpatrick, Christian. "Potteries of Staffordshire." British Heritage. Available online from TheHistoryNet. Retrieved September 4, 2007.

- Rado, P. An Introduction to the Technology of Pottery, 2nd ed. Pergamon Press, 1988. ISBN 0080349307

- Rice, Prudence M. (1987). Pottery Analysis – A Sourcebook. Chicago: University of Chicago Press. ISBN 0226711188

- Utz, George Jacob. The potters wheel from past to present. Dissertation: Thesis (M.F.A.)—Ohio State University 1972. OCLC: 554506

- Warshaw, Josie. The Practical Potter. Anness Pub. Ltd., 2002. ISBN 1843092069

External links

Retrieved December 18, 2007.

- The Origins of the Potter's Wheel multi-page article on Ceramics Today site. www.ceramicstoday.com

- Video of a potter on a potter's wheel shaping clay to form a bottle video.google.com

Credits

New World Encyclopedia writers and editors rewrote and completed the Wikipedia article in accordance with New World Encyclopedia standards. This article abides by terms of the Creative Commons CC-by-sa 3.0 License (CC-by-sa), which may be used and disseminated with proper attribution. Credit is due under the terms of this license that can reference both the New World Encyclopedia contributors and the selfless volunteer contributors of the Wikimedia Foundation. To cite this article click here for a list of acceptable citing formats.The history of earlier contributions by wikipedians is accessible to researchers here:

The history of this article since it was imported to New World Encyclopedia:

Note: Some restrictions may apply to use of individual images which are separately licensed.